Press release

Setting Up a HDPE Corrugated Pipe Plant in Saudi Arabia 2025: A Complete Business & Cost Guide

IMARC Group's "HDPE Corrugated Pipe Manufacturing Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a detailed roadmap for establishing a HDPE corrugated pipe manufacturing plant in Saudi Arabia. The report offers every critical aspect of the setup process, such as unit operations, raw material requirements, utility supply, infrastructural needs, machinery models, labour necessities, transportation timelines, packaging costs, etc.In addition to the operational aspects, the report also provides in-depth insights into HDPE corrugated pipe manufacturing plant cost, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful HDPE corrugated pipe production unit.

Request a Sample Report: https://www.imarcgroup.com/hdpe-corrugated-pipe-manufacturing-plant-project-report/requestsample

What is HDPE Corrugated Pipe?

HDPE (High-Density Polyethylene) corrugated pipe is a durable, lightweight, and flexible piping solution designed for drainage, sewage, and stormwater management. In Saudi Arabia, it is widely used in infrastructure projects, residential developments, and industrial applications due to its corrosion resistance, ease of installation, and long service life, making it ideal for the country's arid and urbanizing regions.

Key Market Trends and Drivers:

The HDPE corrugated pipe industry in Saudi Arabia is experiencing strong growth, driven by massive infrastructure projects, urban development, and expanding water management initiatives under Vision 2030. The demand for efficient stormwater drainage and sewage systems is increasing, while the material's durability and low maintenance requirements enhance its appeal. Additionally, government-led investments in residential, commercial, and industrial construction projects are boosting consumption. Technological advancements in pipe manufacturing, including larger diameters and reinforced wall structures, are also improving performance. Sustainability trends, coupled with long-term cost savings and reduced installation time, are further reinforcing HDPE corrugated pipes as the preferred solution in the Saudi market.

Why Set Up a HDPE Corrugated Pipe Plant in Saudi Arabia

Saudi Arabia's Vision 2030 prioritizes industrial diversification and local manufacturing to reduce oil dependency and expand the non-oil economy. Establishing a HDPE corrugated pipe plant aligns perfectly with this vision, as the chemical sector is one of the key focus industries under the National Industrial Strategy. The Kingdom offers competitive feedstock and energy prices, well-developed industrial zones (Jubail, Yanbu, Rabigh), and strategic access to global markets across Asia, Africa, and Europe. Investors also benefit from government incentives, including financing programs, industrial land grants, and export support through initiatives like "Made in Saudi." Moreover, such projects contribute to job creation, technology transfer, and sustainability goals under the Circular Carbon Economy initiative, reinforcing Saudi Arabia's position as a regional hub for chemical manufacturing and industrial innovation.

Ask Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=8239&flag=C

Steps to Setup an HDPE Corrugated Pipe Manufacturing Cost Analysis Plant in Saudi Arabia

• Feasibility Study & Market Research: Evaluate domestic and GCC demand for HDPE corrugated pipes in water management, sewage, stormwater, and infrastructure projects. Analyze competitors, pricing trends, and regulatory requirements from SASO and the Ministry of Industry.

• Site Selection & Infrastructure: Choose an industrial zone with access to utilities, transport links, and proximity to construction and municipal projects (e.g., Riyadh, Dammam, Jeddah).

• Regulatory Approvals: Obtain industrial licenses, environmental clearances, and compliance certifications for plastic products from SASO.

• Raw Material Procurement: Secure high-quality HDPE resin, color masterbatches, and additives from local or international suppliers.

• Machinery & Equipment: Install extrusion machines, corrugators, cooling tanks, haul-off units, cutting machines, and quality inspection systems for continuous pipe production.

• Plant Layout & Utilities: Design efficient workflow from resin feeding to extrusion, corrugation, cooling, cutting, and packaging. Ensure stable electricity, water supply, and compressed air.

• Quality Control & Testing: Set up labs for pressure testing, dimensional accuracy, impact resistance, and chemical resistance in compliance with SASO standards.

• Workforce Recruitment & Training: Hire skilled technicians, machine operators, quality inspectors, and administrative staff; provide training in operations and safety.

• Production & Distribution Planning: Establish packaging, storage, and logistics for supplying construction companies, municipalities, and industrial projects.

• Cost Analysis & Financial Planning: Calculate CAPEX, OPEX, labor, utilities, raw material costs, break-even units, and ROI for sustainable profitability.

How IMARC Can Help?

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Setting Up a HDPE Corrugated Pipe Plant in Saudi Arabia 2025: A Complete Business & Cost Guide here

News-ID: 4238043 • Views: …

More Releases from IMARC Group

Polylactic Acid Prices in January 2026: Trend Analysis & Forecast

The Polylactic Acid (PLA) Price Index indicates evolving global momentum driven by feedstock cost shifts, bioplastic demand, and regional supply balances. Recent Polylactic Acid (PLA) Prices have reflected moderate volatility across Asia, Europe, and North America due to changing corn-based feedstock economics and sustainable packaging adoption. This report provides a detailed review of the Polylactic Acid (PLA) price trend analysis 2026, Polylactic Acid (PLA) historical price data, and the Polylactic…

Soybean Oil Prices Rise in Q4 2025: Trend Analysis & Forecast

Soybean Oil Price Trend Analysis is essential for understanding how global supply conditions, trade flows, and policy decisions influence pricing movements across major regions. In 2025-2026, prices have remained sensitive to crop output, biodiesel blending requirements, freight costs, and changing procurement strategies. Seasonal harvest cycles and export competitiveness continue to shape short-term fluctuations. This report delivers a structured overview of recent developments, historical performance, and forward-looking price expectations to support…

India Gold Loan Market Forecast 2026-2034: Industry Size, Trends, Expansion and …

According to IMARC Group's report titled "India Gold Loan Market Size, Share, Trends and Forecast by Market Type, Type of Lenders, Application, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Gold Loan Market Report

The India gold loan market size reached USD 3.8 Billion in 2025. Looking ahead, the market is projected to grow and reach USD 5.2 Billion…

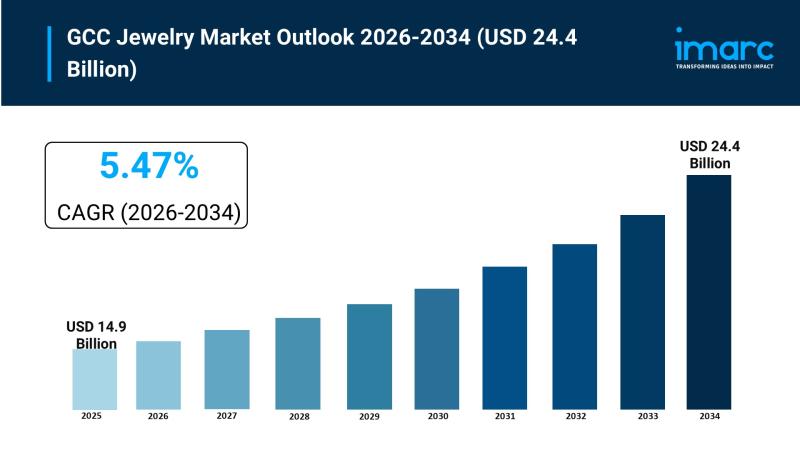

GCC Jewelry Market Size to Reach USD 24.4 Billion by 2034 | With a 5.47% CAGR

GCC Jewelry Market Overview

Market Size in 2025: USD 14.9 Billion

Market Size in 2034: USD 24.4 Billion

Market Growth Rate 2026-2034: 5.47%

According to IMARC Group's latest research publication, "GCC Jewelry Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2026-2034," The GCC jewelry market size was valued at USD 14.9 Billion in 2025. Looking forward, IMARC Group estimates the market to reach USD 24.4 Billion by 2034, exhibiting a CAGR of 5.47%…

More Releases for HDPE

Beyond Numbers: Understanding PCR HDPE Market Size

In this comprehensive report, analysts conduct an in-depth study of the global PCR HDPE market, delving into key factors such as drivers, challenges, recent trends, opportunities, advancements, and the competitive landscape. Utilizing research techniques like PESTLE and Porter's Five Forces analysis, the researchers provide a clear understanding of both the current and future scenarios within the global PCR HDPE industry. Accurate data on PCR HDPE production, capacity, price, cost, margin,…

Latest Trends In Global Recycled HDPE Market

Recycled HDPE, or High-Density Polyethylene, is a versatile and environmentally friendly material derived from the recycling of plastic products made from HDPE.

HDPE is a type of plastic commonly used for items like milk jugs, detergent bottles, and plastic bags. The recycling process for HDPE involves collecting, cleaning, and melting down these used plastic items to create new products.

Request for Sample@

https://mobilityforesights.com/contact-us/?report=20042

Recycled HDPE is valued for its durability, resistance…

Geomembrane manufacturer, HDPE geomembrane factory, geosynthetics supplier

MTTVS® Geosynthetics company specializes in research ,development,production,promotion and application of geosynthetics.And is the world's leading supplier of geosynthetics. Founded in 2014,located in Shandong China.With ISO9001,ISO14001,ISO45001 international authoritative management system certification of powerful large manufucture.We have more than 10 international advanced equipment production lines and a huge professional engineering and technical team.and has successfully consolideated and developed core markets to maximize value for customers.Through the processing of synthetic raw materials.we develop,manufacture…

hdpe geomembrane liner fabric manufacturer,geotextile manufacturer Company,HDPE …

GD Geosynthetics Company is a comprehensive processing enterprise of composite geosynthetics, geotextiles, geomembranes, geogrids, geounits, three-dimensional composite drainage nets, ecological bags, drainage boards. High-level management, high-level scientific research team, conform to the trend of domestic and international chemical fiber market, constantly innovate and update, cater to the market and meet the needs of consumers. Gained the trust of consumers.

Geosynthetics are widely used in anti-seepage treatment of roads, bridges, reservoirs, tunnels,…

Research Focuses on Global HDPE Geomembrane

HDPE Geomembrane Report by Material, Application, and Geography – Global Forecast to 2021 is a professional and in-depth research report on the world's major regional market conditions, focusing on the main regions (North America, Europe and Asia-Pacific) and the main countries (United States, Germany, united Kingdom, Japan, South Korea and China).

The report firstly introduced the HDPE Geomembrane basics: definitions, classifications, applications and market overview; product specifications; manufacturing processes; cost structures,…

Global HDPE Decking Market Research Report 2017

HDPE Decking Revenue, means the sales value of HDPE Decking This report studies HDPE Decking in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with capacity, production, price, revenue and market share for each manufacturer, covering UPM Kymmene Universal Forest Products Advanced Environmental Recycling Technologies Fiberon Azek Building Products Cardinal Building Products Certainteed Corporation Duralife Decking and Railing…