Press release

TOP Laser Cutter for Dye Sublimation & DTF Printing Showcased at FESPA

The FESPA Global Print Expo, a highly anticipated event on the international calendar for the print, signage, and visual communications industries, recently served as the stage for a significant technological debut. Amidst a bustling showcase of cutting-edge machinery and innovative solutions, a new contender emerged to redefine material processing: a state-of-the-art laser system from Mimowork, a Shanghai and Dongguan-based laser manufacturer with two decades of operational expertise. This new system, designed to deliver high-precision, efficient cutting on textiles and other materials, signals a major leap forward for small and medium-sized enterprises (SMEs) seeking to enhance their capabilities and expand their service offerings, particularly in the booming fields of sportswear and outdoor advertising.The Evolution of FESPA: A Hub for Converging Technologies

To understand the full impact of Mimowork's new product launch, it's essential to grasp the scale and significance of the FESPA Global Print Expo. FESPA, which stands for the Federation of European Screen Printers Associations, has grown from its roots as a regional trade body into a global powerhouse for the specialty print and visual communications sectors. The annual Global Print Expo is its flagship event, a must-attend for industry professionals looking to stay ahead of the curve. This year, the focus was squarely on a few key themes: sustainability, automation, and the convergence of traditional printing with new technologies.

The lines between traditional printing and other material processing methods, such as laser cutting(https://www.mimowork.com/our-laser-solutions/) and engraving, are blurring. Print service providers are increasingly looking for ways to add value beyond two-dimensional printing. They want to offer customized, three-dimensional products, intricate signage, and engraved promotional items. This is where Mimowork's new laser cutter makes its mark, fitting perfectly into this trend by providing a robust, versatile tool that complements existing print operations. Its presence at FESPA highlights that specialized material processing is now an integral part of the modern print and visual communications landscape, not a separate, niche industry.

Pioneering Solutions for Dye Sublimation and DTF Printing

The Mimowork system on display at FESPA is a prime example of this convergence, specifically tailored to meet the demands of two key market sectors: dye sublimation and DTF (Direct to Film) printing. Dye sublimation, a popular method for creating vibrant, all-over prints on fabrics like those used in sportswear and fashion, requires a precise post-processing step. The laser cutter excels at this, performing critical functions such as clean-edge cutting and sealing to prevent fabric fraying. The precision of the laser ensures that the cut matches the printed outline perfectly, even with complex or intricate designs, a task that would be difficult and time-consuming with manual methods.

For outdoor advertising flags and banners produced with DTF printing, the Mimowork laser cutter provides a solution to challenges related to large format, weather-resistant materials, and the need for rapid production. The system is capable of working with large-format materials, a necessity for banners and flags. Beyond simply cutting, it can be combined with laser engraving to perform a range of edge treatments, such as creating clean, sealed edges to enhance durability against the elements, punching holes for mounting, or adding decorative details to elevate the final product.

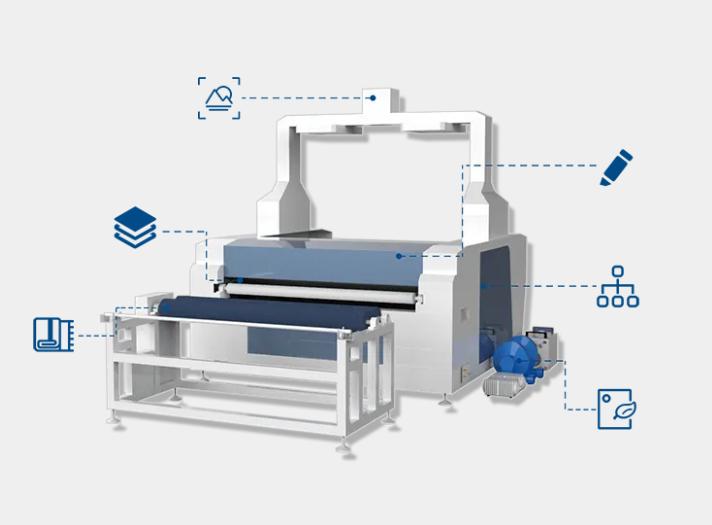

The Power of Automation: Mimo Contour Recognition and Automatic Feeding

What truly sets this system apart and aligns it with the modern trend of automation is the integration of the Mimowork Contour Recognition System and the Automatic Feeding System. These two features embody visual recognition and automated workflow, dramatically improving efficiency and reducing labor costs.

The Mimo Contour Recognition System, equipped with an HD camera, is an intelligent option for laser cutting fabrics with printed patterns. It works by detecting the cutting contours based on the graphic outlines or color contrast on the material. This eliminates the need for manual cutting files, as the system automatically generates the cutting outline, a process that can take as little as 3 seconds, significantly improving production efficiency. It is a fully automatic process that corrects for fabric deformation, deviation, and rotation, ensuring a highly precise cut every time.

Paired with this is the Automatic Feeding System, a continuous feeding solution for materials in a roll. This system works in tandem with a conveyor table, continuously transmitting the roll of fabric to the cutting area at a set speed. This eliminates the need for constant human intervention, allowing a single operator to supervise the machine while it works, increasing productivity and reducing labor costs. The system is also adaptable to a wide range of materials and is equipped with automatic deviation correction to ensure accurate feeding.

Mimowork's Core Competencies: A Legacy of Quality and Customization

Mimowork is not a newcomer to the laser manufacturing scene. With over two decades of deep operational expertise, the company has established a strong reputation for producing reliable laser systems and providing comprehensive processing solutions. The company's core business philosophy is centered on empowering SMEs by giving them access to high-quality, dependable technology that helps them compete with larger enterprises.

One of Mimowork's most significant competitive advantages is its unwavering commitment to quality control. They meticulously control every part of the production chain, ensuring that every laser system they produce-whether it's a laser cutter, marker, welder, or engraver-delivers consistently excellent performance. This level of vertical integration gives their customers confidence in the longevity and reliability of their investment.

Beyond their product quality, Mimowork's primary core competency lies in their ability to provide high-quality equipment and tailored services. The company operates more like a strategic partner than a simple equipment vendor. They go to great lengths to understand each client's unique manufacturing process, technology context, and industry background, offering bespoke solutions that are perfectly suited to the client's needs.

The new laser cutter's debut at FESPA is more than just a product launch; it's a testament to Mimowork's legacy of engineering excellence and customer-focused innovation. By showcasing a device that directly addresses the evolving needs of the print and visual communications industries, Mimowork solidifies its position as a leading solutions provider for businesses seeking to enhance their capabilities. Whether you're an SME looking to upgrade your workshop or a large firm aiming for greater precision, Mimowork's blend of deep expertise, stringent quality control, and commitment to customized solutions provides a clear path to success.

To learn more about Mimowork's comprehensive range of laser systems and processing solutions, visit their official website at https://www.mimowork.com/.

Email:info@mimowork.com

Tel : +86 173 0175 0898

Add :No. 1188 Jiang Yue Road, Minhang District, Shanghai, China

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20-year deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release TOP Laser Cutter for Dye Sublimation & DTF Printing Showcased at FESPA here

News-ID: 4233275 • Views: …

More Releases from MimoWork

Laser Wood Cutter Factory Exhibits High-Speed Cutting Solutions At India Interna …

The INDIA INTERNATIONAL LASER CUTTING TECHNOLOGY EXPO is a crucial event that serves as a nexus where global innovation meets the soaring demand of a rapidly growing local market. For industries in South Asia, particularly India's burgeoning manufacturing sector, this expo is more than just a trade show; it is a barometer of technological trends and a gateway to new opportunities. Against this dynamic backdrop, Mimowork, a top-tier laser manufacturer…

Top Fabric Laser Cutting Machine Factory at ITMA Showcases High-Speed, Accurate …

In the fast-paced and ever-evolving world of textiles, apparel, and technical fabrics, innovation is the cornerstone of progress. The International Textile Machinery Association (ITMA) exhibition serves as the preeminent global platform for showcasing the future of the industry, with a strong emphasis on sustainability, automation, and digital transformation. Amidst this landscape, MimoWork, a results-oriented laser manufacturer with over 20 years of expertise, stands out by presenting a comprehensive suite of…

Top Chinese CO2 Laser Machine Factories Highlight High-Precision, Fray-Free Fabr …

The global textile industry is at a pivotal moment, driven by a powerful trifecta of technological advancements: digitalization, sustainability, and the burgeoning market for high-performance technical textiles. This transformative shift was on full display at Texprocess, the premier international trade fair for the garment and textile processing industry held in Frankfurt, Germany. The exhibition served as a critical barometer for the sector's future, showcasing cutting-edge solutions designed to enhance efficiency,…

A Leading Chinese Laser Engraving Machine Supplier Demonstrates High-Resolution …

The manufacturing landscape is in the midst of a profound revolution, a shift towards greater intelligence, efficiency, and sustainability. At the forefront of this transformation is laser technology, which is evolving beyond simple cutting and engraving to become a cornerstone of smart manufacturing. This evolution was on full display at the recent LASERFAIR SHENZHEN, a pivotal event that showcased the latest innovations driving the industry forward. As a leading hub…

More Releases for Mimo

Top Trends Transforming the Massive MIMO Market Landscape in 2025: Advanced Prod …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

What Will the Massive MIMO Industry Market Size Be by 2025?

In recent years, the enormous mimo market has seen exponential growth. The market is projected to expand from $8.12 billion in 2024 to $11.28 billion in 2025, with a compound annual growth rate (CAGR) of 38.9%. The growth…

The Ultimate Complete Guide To Massive MIMO

The massive multiple input/multi output (MIMO) market is witnessing growth attributed to the increasing new and enhanced software implementation in communication networks with an aim to increase data transfer speed with efficient network connectivity.

Grab PDF To Know More:-https://www.theinsightpartners.com/sample/TIPRE00003165?utm_source=Open_PR&utm_medium=10392

key players influencing the massive MIMO market are CommScope Inc., Ericsson, Huawei Technologies Co., Ltd., Nokia Corporation, Samsung, Sprint Corporation, Verizon Communications Inc., Vodafone Group plc., and ZTE Corporation among others.

Contact Us:

Contact…

Massive MIMO - An Ultimate Technology

The massive multiple input/multi output (MIMO) market is witnessing growth attributed to the increasing new and enhanced software implementation in communication networks with an aim to increase data transfer speed with efficient network connectivity. With the increasing number of device ownership, the connectivity amongst devices is significantly increasing resulting in high data traffic. Thus, massive MIMO is extensively used across diverse industries to reduce data traffic. Also, high signal to…

Massive MIMO Market 2033: Connecting the World at Unprecedented Speeds - Shaping …

The global Massive MIMO Market revenues totalled US$ 3.3 billion in 2022. Overall demand in the market is forecast to increase at 27.4% from 2022 to 2032, according to a recently published Persistence Market Research report. By 2033, the massive MIMO industry is expected to reach a valuation of US$ 37.5 billion.

LTE advance pro technology segment will continue to dominate the global market through 2032. The target segment…

Latest Trends In Global 5G MIMO Antenna Market

Massive MIMO is a cutting-edge antenna technique used in 5G NR networks to improve spectrum efficiency, network capacity, coverage, and possible data speeds.

To accommodate numerous users at once, massive MIMO makes use of a lot of antenna components inside the transmitter and reception antenna panels.

The term MIMO describes the integration of several antennas into a single wireless device with the goal of boosting data transmission speeds.

Request for Sample@ https://mobilityforesights.com/product/5g-mimo-antenna-market/

This…

Massive MIMO Market

MIMO stands for multiple input and multiple output which is a radio communications technology and is able to provide higher link capacity and reliability by using multiple transmission and reception antennas. In this system, same data gets transmitted over the same route via multiple antennas. Due to this, in the reception antenna, every signal reaches through a different path resulting in more reliable data.

The massive MIMO market is expected to…