Press release

Top Fabric Laser Cutting Machine Factory at ITMA Showcases High-Speed, Accurate Cutting for Apparel Fabrics

In the fast-paced and ever-evolving world of textiles, apparel, and technical fabrics, innovation is the cornerstone of progress. The International Textile Machinery Association (ITMA) exhibition serves as the preeminent global platform for showcasing the future of the industry, with a strong emphasis on sustainability, automation, and digital transformation. Amidst this landscape, MimoWork, a results-oriented laser manufacturer with over 20 years of expertise, stands out by presenting a comprehensive suite of laser cutting solutions that align perfectly with these global trends.MimoWork's presence at ITMA is not merely about exhibiting machinery; it is a clear demonstration of how their technology is redefining textile manufacturing by offering high-speed, accurate, and environmentally conscious solutions. By integrating state-of-the-art automation and advanced processing capabilities, their laser systems are more than just tools-they are a strategic investment in efficiency, quality, and a sustainable future for the entire textile supply chain.

Engineered for Diverse Fabric Applications

MimoWork's laser cutting technology(https://www.mimowork.com/contour-laser-cutter/) is designed to provide unparalleled versatility, catering to three key categories of fabrics that are critical to modern textile production. Their machines deliver tailored solutions that address the specific challenges and requirements of each material type.

Synthetic Fibers: Synthetic fabrics like polyester, nylon, and synthetic leather are a cornerstone of modern apparel and home textiles. A significant challenge with these materials is preventing fraying and ensuring clean, durable edges. MimoWork's laser cutting machines utilize the inherent thermal properties of these materials to achieve perfectly sealed edges during the cutting process. The laser's heat melts and fuses the edges, eliminating the need for post-processing steps like sewing or overlocking. This not only prevents unraveling but also streamlines the manufacturing workflow, boosts production efficiency, and reduces labor costs. The result is a slim, fine incision and an intact, high-quality edge, all without material distortion.

Functional and Technical Textiles: The demand for high-performance textiles used in safety, medical, and automotive applications is rapidly growing. Materials such as Aramid fibers (e.g., Kevlar), fiberglass, and other high-tech composites require a cutting method that is precise and gentle to preserve their structural integrity. MimoWork's laser cutters provide a non-contact, high-precision solution that avoids the mechanical stress and potential damage caused by traditional knife cutting. The laser beam, with a fineness of less than 0.5mm, ensures delicate and intricate designs can be cut with extreme accuracy, making it ideal for products like protective apparel, medical fabrics, and automotive safety components. This capability ensures that the high-performance properties of these materials are maintained, meeting the stringent quality standards of critical applications.

Organic and Natural Fibers: While synthetic and technical fabrics benefit from the laser's thermal properties, natural fibers like organic cotton, wool, and other plant-based materials require a different approach. MimoWork's machines are equipped to handle these delicate fabrics, providing clean cuts without fraying or scorching. The versatility of the laser technology allows for the creation of complex patterns, intricate lace designs, and ventilation holes, catering to the growing market for customizable and personalized apparel and accessories. The non-contact nature of the laser ensures that even the most delicate materials are not stretched or deformed during processing, preserving their natural drape and feel.

Aligning with ITMA's Core Trends

The true value of MimoWork's technology lies in its profound alignment with the core themes of the ITMA exhibition. The company's laser systems are a practical embodiment of the industry's shift toward a more intelligent, efficient, and responsible future.

Automation and Digitalization

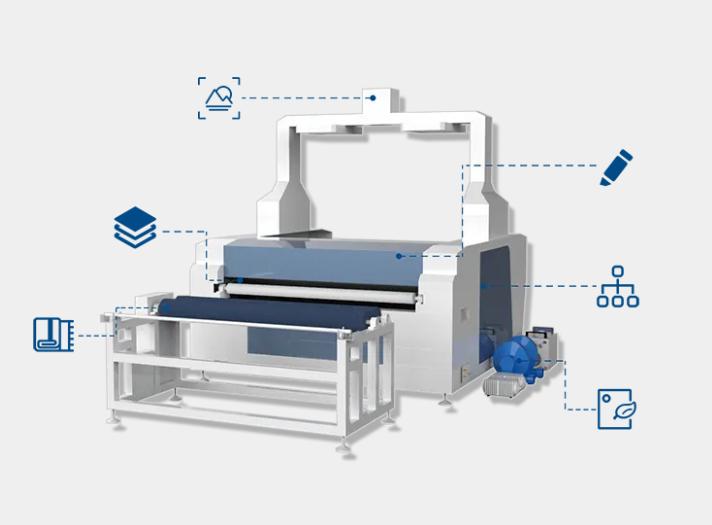

Automation is at the heart of modern manufacturing, and MimoWork's laser cutting machines exemplify this trend. Their systems feature a range of automated functionalities that reduce labor costs, increase productivity, and minimize human error. Key features include:

Automatic Feeding Systems: Roll fabrics are automatically fed onto the conveyor table, enabling continuous, unattended production. This seamless material handling significantly boosts throughput and streamlines the entire workflow.

Vision Recognition Systems: For printed fabrics, a CCD camera automatically detects and cuts along the contours of the printed design, ensuring precise alignment and eliminating the need for manual positioning. This is particularly crucial for applications like sublimation sportswear and printed banners, where accuracy is paramount.

Intelligent Software: MimoWork's software includes advanced features like MimoNEST, which intelligently nests cutting patterns to optimize material usage and minimize waste. This digital integration makes the entire process more efficient and cost-effective.

Sustainability and Environmental Protection

In an era where environmental responsibility is paramount, MimoWork's laser cutting solutions offer a compelling alternative to traditional manufacturing methods. The technology contributes to a greener industry in several ways:

Waste Reduction: The high-precision cutting and intelligent nesting software of MimoWork's machines ensure maximum material utilization, dramatically reducing fabric waste. Laser cutting also enables the easy recycling and upcycling of fabric scraps, diverting waste from landfills and contributing to a circular economy.

Chemical-Free Process: Unlike traditional methods that may require chemical dyes or solvents, laser cutting is a dry, non-contact process that eliminates the use of hazardous substances. This not only protects the environment but also creates a safer working environment.

Minimal Resource Consumption: Laser cutting fabric does not require water, a scarce resource in many areas. Furthermore, MimoWork machines are designed for high energy efficiency and have a longer operational lifespan than traditional equipment, reducing the need for frequent replacements and disposal.

High Precision and Diversified Processing

The versatility and accuracy of MimoWork's laser systems are a testament to their commitment to high-quality manufacturing. The precision of the laser beam allows for the cutting of highly complex and intricate designs that would be impossible with manual or mechanical methods. This capability is essential for creating everything from fine lace and decorative patterns to functional air holes and micro-perforations in technical fabrics. By offering a single machine that can handle a wide range of materials and complex designs, MimoWork provides a flexible solution that empowers businesses to meet diverse market demands, from mass production to highly customized, on-demand jobs.

Conclusion

MimoWork's participation in the ITMA exhibition highlights its role as a key innovator in the textile industry. By showcasing laser cutting systems that are not only high-speed and accurate but also deeply integrated with the principles of automation and sustainability, the company is demonstrating its commitment to shaping a more efficient, responsible, and digitally advanced future. Their machines are more than just equipment; they are a strategic asset that provides manufacturers with a competitive edge, enabling them to meet the demands of a global market that values both performance and environmental consciousness. For businesses seeking to navigate the next generation of textile manufacturing, MimoWork offers a powerful and comprehensive solution, solidifying its position as a trusted partner in progress.

For more information, please visit Mimowork's official website: https://www.mimowork.com/

Email:info@mimowork.com

Tel : +86 173 0175 0898

Add :No. 1188 Jiang Yue Road, Minhang District, Shanghai, China

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20-year deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Top Fabric Laser Cutting Machine Factory at ITMA Showcases High-Speed, Accurate Cutting for Apparel Fabrics here

News-ID: 4233268 • Views: …

More Releases from Mimowork

Laser Wood Cutter Factory Exhibits High-Speed Cutting Solutions At India Interna …

The INDIA INTERNATIONAL LASER CUTTING TECHNOLOGY EXPO is a crucial event that serves as a nexus where global innovation meets the soaring demand of a rapidly growing local market. For industries in South Asia, particularly India's burgeoning manufacturing sector, this expo is more than just a trade show; it is a barometer of technological trends and a gateway to new opportunities. Against this dynamic backdrop, Mimowork, a top-tier laser manufacturer…

TOP Laser Cutter for Dye Sublimation & DTF Printing Showcased at FESPA

The FESPA Global Print Expo, a highly anticipated event on the international calendar for the print, signage, and visual communications industries, recently served as the stage for a significant technological debut. Amidst a bustling showcase of cutting-edge machinery and innovative solutions, a new contender emerged to redefine material processing: a state-of-the-art laser system from Mimowork, a Shanghai and Dongguan-based laser manufacturer with two decades of operational expertise. This new system,…

Top Chinese CO2 Laser Machine Factories Highlight High-Precision, Fray-Free Fabr …

The global textile industry is at a pivotal moment, driven by a powerful trifecta of technological advancements: digitalization, sustainability, and the burgeoning market for high-performance technical textiles. This transformative shift was on full display at Texprocess, the premier international trade fair for the garment and textile processing industry held in Frankfurt, Germany. The exhibition served as a critical barometer for the sector's future, showcasing cutting-edge solutions designed to enhance efficiency,…

A Leading Chinese Laser Engraving Machine Supplier Demonstrates High-Resolution …

The manufacturing landscape is in the midst of a profound revolution, a shift towards greater intelligence, efficiency, and sustainability. At the forefront of this transformation is laser technology, which is evolving beyond simple cutting and engraving to become a cornerstone of smart manufacturing. This evolution was on full display at the recent LASERFAIR SHENZHEN, a pivotal event that showcased the latest innovations driving the industry forward. As a leading hub…

More Releases for ITMA

YIXUN MACHINERY Showcases Innovation As A High-Performance Warp Knitting Machine …

Danyang Yixun Machinery Co., Ltd., a recognized High-Performance Warp Knitting Machine Manufacturer(https://www.yixun-machine.com/warp-knitting-machine/), recently highlighted its latest technological advancements at ITMA, the world's most influential textile and garment technology exhibition. During this premier event, the company demonstrated its commitment to engineering excellence by showcasing specialized machinery designed for the production of technical textiles and composite reinforcements. As global industries increasingly pivot toward high-strength, lightweight materials, YIXUN MACHINERY's participation at ITMA serves…

GrandStar Shines at ITMA Singapore 2025 with Its Next-Generation Tricot Warp Kni …

Image: https://www.grandstarcn.com/uploads/web1.jpg

During ITMA Singapore 2025 (October 28-31), GrandStar Warp Knitting Company made a powerful impression by unveiling its latest Tricot warp knitting machine [https://www.grandstarcn.com/curtain-machine-karl-mayer-warp-knitting-machine-raschel-machine-for-lace-curtain-fabric.html], which quickly became one of the most talked-about highlights of the exhibition's opening day. The booth attracted a continuous flow of industry professionals eager to witness GrandStar's innovations in warp knitting technology - machines built upon the values of efficiency, stability, and cost optimization.

GrandStar COP4E+M: The…

Fibre2Fashion Facilitates Key UK-India Collaboration Dialogue at ITMA Asia + CIT …

Singapore, October 2025:

At the prestigious ITMA Asia + CITME Singapore 2025, Fibre2Fashion once again emerged as the trusted platform connecting global textile industry leaders. The team had an insightful interaction with Mr. Jason Kent, CEO of the British Textile Machinery Association (BTMA), discussing the strengthening partnership between the UK and India.

During the conversation, Mr. Kent highlighted that the UK-India Free Trade Agreement (FTA) is set to become a…

ITMA 2019: Predictive maintenance secures production processes in the fiber indu …

Neukirchen-Vluyn (Germany), May 2, 2019. The production of textiles and clothing will be the focus of this year's ITMA 2019 in Barcelona. From June 20 to 26, 2019, the German specialist SCHWING Technologies will be presenting thermal cleaning solutions for polymer-contaminated production tools. In hall 7 / booth C120, SCHWING experts, Managing Director Thomas Schwing and Head of Sales Virgilio Perez Guembe, will inform about the potentials and advantages of…

Abercrombie Textiles Announces Introductions for 2012 ITMA Market Set To Differe …

Abercrombie Textiles, a domestic manufacturer of jacquard and dobby fabrics for the residential furniture, jobber, hospitality, outdoor, recreational vehicle, healthcare and contract markets, announces a dual design plan for introductions at the upcoming 2012 Summer Showtime-ITMA Market. With the 2012 introductions, Abercrombie Textiles will present industry buyers with two collections that clearly differentiate between the ABERCROMBIE TEXTILES brand and their newly acquired CONE DECORATIVE brand.

Abercrombie’s North Carolina based design…

ITMA ASIA + CITME 2008 | Asia’s largest international textile machinery and ac …

This first combined exhibition, "ITMA ASIA + CITME 2008" will be held at the Shanghai New International Expo Centre in Shanghai from 27 to 31 July 2008. Starting from 2008, a combined show known as “ITMA ASIA + CITME 2008” will be held in China, scheduled to take place every two years. ITMA ASIA – Asian International Exhibition of Textile Machinery – and CITME – China International Textile Machinery Exhibition…