Press release

Flexible End Load Cartoner Market to Reach USD 5,448 Million by 2031 Top 10 Company Globally

Flexible end-load cartoners are horizontal cartooning machines designed to establish, load and close cartons at the end of the carton (end-load), optimized to handle flexible packaged products such as pouches, sachets, bags, bottles and tray-packed goods; they are valued for high throughput, rapid changeover, and the ability to feed a wide mix of product formats in food, confectionery, pharmaceuticals, personal care and household segments. End-load cartoners are sold as intermittent- or continuous-motion systems, from compact benchtop models used for low-to-mid speeds to fully automated high-speed lines integrated with counting, collating and secondary case-packing. The flexible qualifier reflects mechanical and software design choices (servo drives, intelligent feeders, vision-guided insertion, modular tooling) that let one machine run many SKUs with minimal downtime an increasingly important capability for brand owners pursuing SKU proliferation, e-commerce-ready packaging and sustainable carton formats that replace plastic trays or overwraps. Modern vendors bundle the machine, HMI recipe management, inspection/vision systems and integration services so buyers receive a production-ready solution that dovetails with upstream dunnage and downstream case-packing lines.The flexible end load cartoner market at approximately USD 3,564 million in 2024, and a prudent planning CAGR of 6,3 % through 2031, which captures sustained automation demand, SKU diversification needs and mid-term factory modernizations across food & beverage, pharma and personal-care customers. The 2024 ASP market of USD 15,000 per unit implies roughly 237,500 units sold globally in 2024. average cost-of-goods-sold per machine of USD 9,000, yielding an estimated gross profit per unit of USD 6,000 and a factory gross margin of 40% per machine. Based on OEM and global manufacturing footprints, full-machine annual production capacity is estimated at roughly 300,000 units per year.

Latest Trends and Technological Developments

The flexible end-load cartoner markets most important recent trends are rapid adoption of servo-driven changeover systems for sub-minute format swaps, integration of vision and pick-and-place robotics for delicate product insertion, expanded modularity to support sustainable carton formats (reduced board, no internal plastic trays), and the rise of rental or turnkey carton-as-a-service offerings for short-run production. Notable dated vendor signals include Bradman Lake promoting its SL903 series and associated cascade loader at PACK EXPO and industry shows (coverage through 2024 to 2025 highlighted new high-speed and compact end-load cartoners). R.A. Jones (Coesia) recently announced the mid-speed Alterion CL-170 at PACK EXPO as a lower-cost, flexible option for mid-sized producers, underlining vendor focus on affordability and flexibility for smaller lines. Syntegon and other major OEMs showcased intelligent infeed and MagTRAC solutions for end-load cartoners during trade events in 2024 and 2025, demonstrating how intelligent infeeds and servo systems are being bundled with cartoners to shorten downtime and increase throughput. These dated product rollouts and show demonstrations in 2024 to 2025 show the technology trajectory and OEM responses to the markets need for versatility and sustainability.

Asia-Pacific is the largest regional buyer and manufacturing base for flexible end-load cartoners due to the concentration of food, beverage, pharmaceutical and personal-care contract manufacturers and brand-owned factories across China, India, Taiwan, South Korea, Japan and increasingly Southeast Asia. The regions combination of domestic consumer demand, large-scale contract packers, and rapid expansion of small-format production lines for e-commerce and retail have driven strong demand for modular, flexible cartoning machines. Vendors maintain local service hubs and demonstration centers in APAC to shorten integration cycles for customers and support fast calibration and spare-part supply; this proximity is a significant purchasing factor for high-uptime lines. Recent market commentary and vendor announcements reinforce APACs leading share in installations and growing appetite for automation across factory sizes.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5047145

Flexible End Load Cartoner by Type:

Automatic Cartoner

Semi Automatic Cartoner

Robotic Cartoner

Others

Flexible End Load Cartoner by Application:

Food Industry

Beverage Industry

Pharmaceutical Industry

Industrial Packaging

Others

Global Top 10 Key Companies in the Flexible End Load Cartoner Market

Bosch Packaging Technology

Bradman Lake Group

LEAD Packaging Technologies

Unista

Marchesini Group

IMA Group

Klikklok International

AFA Systems

Krones AG

Coesia S.p.A.

Regional Insights

ASEAN is a unit-growth hotspot for flexible end-load cartoners, where rising middle classes, expanding foodservice and snack segments, and growth in pharmaceutical packaging create frequent mid-speed cartoner demand. Indonesia, in particular, is notable because its large domestic market and expanding manufacturing base have encouraged both local assembly of packaging lines and increasing imports of flexible cartoners for bakery, snack, condiment and FMCG packaging. The typical ASEAN purchase mix skews toward mid-ASP machines (compact servo cartoners and intermittent-motion models) and retrofit/used equipment for smaller converters, while Singapore and Malaysia pilot higher-end automated lines for premium and export-oriented brands. Vendors and distributors are expanding local demonstration lines, training and spare-parts stocks across ASEAN to capture first-mover mid-volume opportunities as producers migrate from semi-manual to fully automated cartoning.

The sector faces several constraints that shape procurement cycles and margins. First, lead times and capital intensity: high-speed turnkey cartoning lines require long lead times for engineering and integration, which tightens order flow and creates project-timing risk for buyers. Second, labor and skills: successful deployment requires trained technicians and maintenance regimes, and in regions with shallow technical labor pools OEMs must invest heavily in training and service. Third, price competition and commoditization at the lower end compress margins for suppliers who must still offer high reliability and compliance for food and pharma customers. Fourth, sustainability and material transitions: carton-only formats and recycled board change mechanical handling and closing dynamics, requiring R&D and tooling updates. Fifth, regulatory and validation demands in pharmaceutical cartoning (serialization, tamper-evidence, clean-room compatibility) raise the bar for vendors serving regulated markets and increase sales-cycle length. These structural constraints are evident in industry surveys and vendor roadmaps that highlight service and integration as key differentiators.

Suppliers and integrators that will capture the largest share combine modular mechanical platforms with standardized servo libraries, offer rapid-change tooling and digital recipe management, and pair machines with vision-based quality inspection and predictive maintenance services. Offering flexible financing, rental and pilot-line or on-site test cells helps mid-sized customers adopt automated cartoning without onerous capex. For buyers, prioritizing machines with robust changeover and digital recipe capabilities yields rapid ROI when running multi-SKU campaigns, while prioritizing vendors with local service footprints in APAC/ASEAN reduces downtime risk. For investors, attractive plays include OEMs expanding retrofit accessories (robotic feeders, vision) that increase aftermarket recurring revenues, rental/ATE businesses that smooth cyclical capital spending, and regional distributors building service and spare ecosystems in Indonesia and neighboring ASEAN markets.

Product Models

Flexible end load cartoners are packaging machines designed to load products horizontally into cartons, widely used in food, pharmaceutical, and consumer goods industries. They provide versatility and efficiency, with different automation levels to suit production needs.

Automatic cartoners for high-speed continuous operations. Notable products include:

IWK SC Series IWK Verpackungstechnik: High-speed automatic cartoner for pharmaceuticals and cosmetics with quick changeovers.

Bosch Sigpack TTM Syntegon (Bosch Packaging): Modular automatic cartoner offering flexibility for food and healthcare packaging.

Marchesini MA 80 Marchesini Group: Compact, efficient automatic cartoner designed for blister packs and bottles.

CAM HV CAM Packaging Machines: Automatic horizontal cartoner ideal for high-speed carton loading.

Uhlmann C 130 Uhlmann Pac-Systeme: Automatic cartoner specialized for pharmaceutical blister and bottle packaging.

Semi automatic cartoners for medium-scale flexible packaging. Examples include:

Adco 15SVE Adco Manufacturing: Semi-automatic cartoner with manual product loading and automatic carton closing.

Economode Semi-Auto Cartoner Economode Packaging: Cost-effective cartoner for small to mid-scale operations.

MGS Eclipse Semi-Automatic Cartoner MGS: Compact semi-automatic solution for short-run packaging.

PMI Semi-Auto Cartoner PMI Cartoning: Versatile semi-automatic cartoner for flexible packaging needs.

EconoCartoner Spartan Econocorp: Rugged semi-auto cartoner designed for entry-level automation.

Robotic cartoners that integrate advanced robotics for precision and adaptability. Notable products include:

Bosch Sigpack TTMP Syntegon (Bosch Packaging): Robotic cartoner enabling complex product loading with modular design.

Schubert TLM Cartoner Gerhard Schubert GmbH: Robotics-driven cartoner offering unmatched flexibility and efficiency.

Fanuc Robotic Cartoner System Fanuc: Robotic cartoner integrating Fanuc robots for precision handling.

JLS Osprey Robotic Cartoner JLS Automation: Robotic cartoner ideal for fragile and irregular-shaped products.

Adco Robotic Top Load Cartoner Adco Manufacturing: Robotic end load system designed for high-speed continuous operation.

Flexible end load cartoners are a mature but innovation-active segment of packaging machinery, with an estimated focused market size of about USD 3,564 million in 2024 and a modeled CAGR of 6,3 % through 2031 as manufacturers worldwide seek faster changeovers, higher uptime and sustainable carton formats. Unit volumes depend on product mix and geography, and transparent ASP sensitivity at USD 15,000 implies a plausible 2024 shipment range of 237,500 units; Asia Pacific and ASEAN (including Indonesia) will drive most unit growth due to factory expansions, contract packer penetration and e-commerce packaging needs. Vendors that combine modularity, robust local service and finance/rental options will best capture the growth opportunity while managing lead-time and integration risk.

Investor Analysis

What investors should note is that flexible end-load cartoners sit at the intersection of recurring food and pharma packaging demand and the secular move to automation and SKU proliferation; how investors capture value is by backing OEMs with strong aftermarket service and retrofit portfolios, investing in rental/ATE operators that convert cyclical capex into utilization revenue, or financing regional distributors that control spare-parts and training in fast-growing APAC/ASEAN markets. Why this matters now is because recent vendor innovation (servo modularity, vision inspection, robotic feeders) and rising local production in Indonesia and neighboring ASEAN countries create a 25 year window where service-enabled suppliers and rental operators can convert factory modernizations into predictable annuity streams. Key diligence points include installed-base data, service penetration, average order lead time, retrofit accessory attach rates, and signed reseller or OEM supply agreements in target ASEAN countries.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5047145

5 Reasons to Buy This Report

It reconciles multiple public market sources into a defensible 2024 baseline and provides a transparent CAGR to 2031 to support scenario modelling.

It converts revenue into practical unit ranges using explicit ASP sensitivity bands so planners can test capacity and manufacturing economics.

It documents dated product and trade-show developments that indicate vendor roadmaps and buyer options.

It provides granular APAC and ASEAN insight so distributors and investors can prioritize local assembly, spare-parts stocking and training investments to shorten lead times.

It profiles the competitive set and strategic levers modularity, vision/robotics add-ons, rental/finance models and service penetration that determine which suppliers will scale margins and share.

5 Key Questions Answered

What is a defensible global market size for flexible end-load cartoners in 2024 and which CAGR should financial models use to 2031?

What ASP bands are realistic for entry, mid-range and high-end end-load cartoners, and what do those prices imply about global unit shipments in 2024?

Which recent dated vendor/product announcements (20242025) materially change machine capability and buyer choice for flexible cartoning?

How will Asia and ASEAN influence unit growth and which regional service investments shorten commercial ramp-time?

Which business models generate the most durable returns and which KPIs should investors prioritize in diligence?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Flexible End Load Cartoner Market to Reach USD 5,448 Million by 2031 Top 10 Company Globally here

News-ID: 4188844 • Views: …

More Releases from QY Research

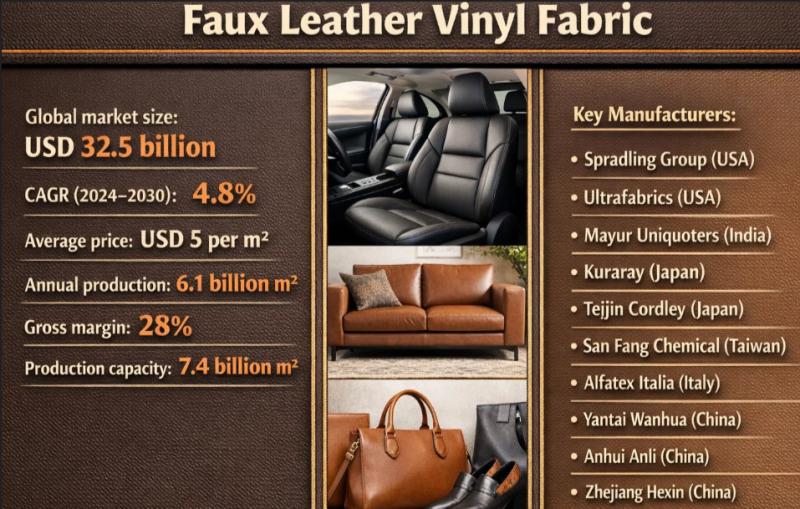

Why Faux Leather Vinyl Fabric Is Replacing Genuine Leather Across Automotive, Fu …

Problem

Manufacturers using genuine leather faced rising raw material costs, inconsistent quality, limited color consistency, and supply chain volatility. Natural leather also posed challenges related to moisture sensitivity, maintenance requirements, and regulatory scrutiny over animal welfare and environmental impact. These issues increased production costs and limited scalability across automotive interiors, furniture, fashion, and commercial upholstery.

Solution

Producers increasingly adopted Faux Leather Vinyl Fabric, a synthetic material typically based on PVC or PU coatings…

Global and U.S. Metal Bellows Expansion Joints Market Report, Published by QY Re …

QY Research has released a comprehensive new market report on Metal Bellows Expansion Joints, refers to flexible mechanical components made from thin-walled, corrugated metal (bellows) designed to absorb thermal expansion, vibration, and mechanical movement in piping and duct systems. They help protect pipes, equipment, and structures by compensating for axial, lateral, angular, or combined movements caused by temperature changes, pressure fluctuations, or seismic activity, and are widely used in power…

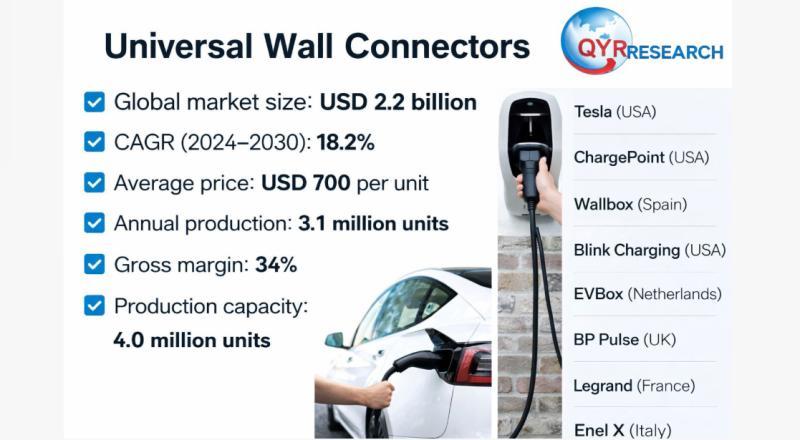

Global and U.S. Universal Wall Connectors Market Report, Published by QY Researc …

QY Research has released a comprehensive new market report on Universal Wall Connectors, wall-mounted AC electric vehicle (EV) charging devices designed to deliver safe, efficient, and interoperable charging across multiple vehicle brands and connector standards. Supporting protocols such as Type 1 (SAE J1772), Type 2 (IEC 62196), and region-specific configurations, universal wall connectors are foundational infrastructure for residential garages, workplaces, commercial parking, fleet depots, and multi-unit dwellings. As EV adoption…

Top 30 Indonesian Paper Manufacturing Public Companies Q3 2025 Revenue & Perform …

1) Overall companies performance (Q3 2025 snapshot)

PT Indah Kiat Pulp & Paper Tbk (INKP) Integrated pulp & paper

PT Pabrik Kertas Tjiwi Kimia Tbk (TKIM) Paper and cultural products

PT Toba Pulp Lestari Tbk (INRU) Pulp producer

PT Suparma Tbk (SPMA) Industrial & consumer paper products

PT Indonesia Fibreboard Industry Tbk (IFII) Fibreboard & related materials

PT SLJ Global Tbk (SULI) Forestry & wood-linked products

PT Inter Delta Tbk (INTD)…

More Releases for Cartoner

Global Flexible End Load Cartoner Market Size, Market Share, Industry Analysis R …

Global Info Research's report offers key insights into the recent developments in the global Flexible End Load Cartoner market that would help strategic decisions. It also provides a complete analysis of the market size, share, and potential growth prospects. Additionally, an overview of recent major trends, technological advancements, and innovations within the market are also included. Our report further provides readers with comprehensive insights and actionable analysis on the…

United States Beverage Cartoner Industry Sector Trends 2025: Top Players, Smart …

DataM Intelligence has released an in-depth research report on "Beverage Cartoner Market Size 2025". This report delivers power-packed insights into key growth drivers, market segmentation, regional trends, CAGR forecasts, revenue performance of top players, and emerging opportunities. Gain a 360° market perspective with detailed analysis on value, volume, and future development trends your ultimate guide to spotting high-impact opportunities and staying ahead in this dynamic market.

Latest M&A (July-September 2025)

Market-wide M&A…

Beverage Cartoner Market Analysis, Insight, & Scope, Opportunities, Developments …

Beverage cartoner market was valued at USD 710.71 million in 2022 and is expected to reach USD 1082.47 million by 2030, registering a CAGR of 5.40% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically…

Beverage Cartoner Market Analysis, Insight, & Scope, Opportunities, Developments …

Beverage cartoner market was valued at USD 710.71 million in 2022 and is expected to reach USD 1082.47 million by 2030, registering a CAGR of 5.40% during the forecast period of 2023 to 2030. In addition to the insights on market scenarios such as market value, growth rate, segmentation, geographical coverage, and major players, the market reports curated by the Data Bridge Market Research also include in-depth expert analysis, geographically…

Sleeve Cartoner from ÉLITER Packaging Machinery Goes to ENSURE in the United St …

ÉLITER Packaging Machinery, manufacturer of secondary packaging equipment has completed a project with the nutrition drinks brand ENSURE in the United States to install a cartoning machine to wrap bottles of nutritional shakes with cardboard sleeve and in a 2x3 multipack.

Zhiwei Bao, general manager at ÉLITER Packaging Machinery, family-owned business located in Wenzhou, China, manufacturer and global supplier of cartoner, overwrapping machine and wrap-around sleever, comments that this is a…

Global Automatic Cartoner for Medical Market Huge Growth Opportunity between 202 …

LP INFORMATION recently released a research report on the Automatic Cartoner for Medical market analysis, which studies the Automatic Cartoner for Medical's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global "Automatic Cartoner for Medical Market 2020-2025" Research Report categorizes the global Automatic Cartoner for Medical market by key players, product type, applications and regions,etc. The report also covers the latest…