Press release

Wafer Level Vacuum Laminator Market to Reach USD 355 Million by 2031 Top 10 Company Globally

Wafer-level vacuum laminators are precision process tools used to bond films, adhesive tapes, protective covers and thin-sheet materials to wafers and wafer-sized substrates under controlled vacuum and thermal conditions; they are central to wafer-level packaging (WLP), fan-out and wafer-level chip-scale packaging (WLCSP) flows, as well as to certain high-precision PCB build-up, flexible-display and optics assembly steps where air-free, bubble-free lamination and exact pressure control determine yield. These systems range from benchtop, small-wafer units for R&D and pilot production to automated, multi-chamber production machines that integrate carrier-film handling, vacuum diaphragm presses and flattening stages; the equipment is sold into semiconductor OSATs, advanced packaging fabs, MEMS and sensor manufacturers, and specialty electronics converters that require high first-pass yield and low particulate/void formation during lamination. The tool family therefore sits at the intersection of advanced packaging demand, wafer throughput economics and the increasing complexity of multi-die, multi-layer packaging stacks.The wafer-level vacuum laminator equipment market of USD 237 million in 2024. For growth to 2031 we model a central scenario of 5,9% CAGR to 2031, this produces a projected market in the range of USD 355 million by 2031. For an ASP of USD 1,5 million per unit, the market implies 160 units sold in 2024.

Latest Trends and Technological Developments

Recent industry activity is driven by continued expansion of wafer-level packaging, rising interest in fan-out and panel-level packaging alternatives, higher wafer sizes and automation for throughput, and supply-chain strengthening for critical vacuum and dry-processing subsystems. On October 2024 the U.S. CHIPS-era announcement around Edwards Vacuum (dry vacuum pump manufacturing) and associated efforts to secure vacuum-equipment supply chains signalled government-level emphasis on reliable vacuum componentry for semiconductor toolmakers and fabs, which benefits laminator manufacturers that depend on high-performance pumps and vacuum systems. In 2024 to 2025 multiple niche equipment suppliers exhibited updated multi-stage vacuum laminators and automated handling upgrades at regional trade shows (TPCA and Semicon Europa coverage through 2024 to 2025), demonstrating shorter cycle times and improved diaphragm/flattening sequences for lower void rates. More recently, industry groupings addressing wafer-level packaging efficiency and panel-level packaging alternatives have gained traction; for example, consortium and industrial commentary around new wafer-to-panel flows surfaced through 2025 (Resonacs JOINT3 consortium activity noted Sept 2025), indicating that laminator tools will be required to adapt to new substrate sizes and bonding methods. These dated signals vacuum-supply industrial policy (Oct 2024), equipment refreshes at trade shows 2024 to 2025, and panel/WLP consortia activity (Sept 2025) are shaping product roadmaps toward larger-area handling, integrated vacuum sub-systems and enhanced automation.

Asia-Pacific is the dominant regional market for wafer-level vacuum laminators because it concentrates wafer-level packaging, OSAT providers, PCB and advanced substrate production, and major consumer-electronics and sensor OEMs. Country-level dynamics place China, Taiwan, South Korea, Japan and Singapore at the center of demand: OSAT growth in Taiwan and China and increased packaging capacity in South Korea and Japan directly translate into new line-level laminator purchases, pilot rigs and spare-tool buys. Supplier directories show a dense cluster of equipment manufacturers and custom integrators in East Asia, and distributor/rental networks favor APAC service footprints. Regional market studies indicate APAC captured the largest share of vacuum lamination equipment demand in 2023 to 2024 and will continue to be the primary growth engine for the tool class through 2031 given ongoing packaging upgrades and regional investments in semiconductor manufacturing capacity.

Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/5049009

Wafer Level Vacuum Laminator by Type:

Hot Press Vacuum Laminator

UV Curing Laminator

Normal Temperature Laminator

Wafer Level Vacuum Laminator by Application:

Advanced Packaging

MEMS Manufacturing

3D Integration

Global Top 10 Key Companies in the Wafer Level Vacuum Laminator Market

Nikko

EV Group

SUSS MicroTec

Tokyo Electron

Applied Materials

ELEADTK

S3 Alliance

GTI Technologies

USUNTEK

Powatec

Regional Insights

ASEAN is an emerging consumer of wafer-level vacuum laminators rather than a major manufacturing base for high-end wafer-level packaging today, but the region is rapidly maturing as contract manufacturing and localized assembly expand. Indonesia is notable for two reasons: first, its rapidly growing electronics assembly and contract PCBA activity creates demand for smaller bench and mid-range vacuum laminators used in substrate lamination and PCB build-up; second, broader regional incentive programs and supply-chain diversification trends (companies relocating or adding capacity in Vietnam, Malaysia and Indonesia) are increasing demand for higher-throughput packaging tools over a multi-year horizon. Expect ASEAN demand to be concentrated initially in lower-ASP tools and retrofit upgrades, with gradual uptake of higher-spec laminators as local OSAT ecosystems deepen and as global OEMs localize packaging and testing activities. Distributor tender notices and regional trade-show participation in 20242025 corroborate rising inquiries and first-tier installations across ASEAN hubs.

The wafer-level vacuum laminator segment faces several structural challenges that shape adoption speed and supplier economics. First, tool demand is tightly coupled to wafer-level packaging cycles and OSAT capital plans, creating cyclical demand that can compress utilisation and order books when packaging investment slows. Second, high precision and cleanliness requirements (particle control, outgassing, uniform pressure) mean long tool qualification cycles and service demands; suppliers must maintain strong field service and spare parts footprints, which is costly to scale globally. Third, component supply particularly dry vacuum pumps, diaphragm seals, high-precision motion stages and cleanroom-grade automation can be constrained by broader vacuum-equipment supply dynamics, a risk underscored by 20242025 efforts to localize vacuum-pump manufacturing. Fourth, evolving packaging formats (larger panels, heterogeneous integration stacks) require laminator re-engineering for size handling and new bonding chemistries, which increases R&D and capital burden for equipment vendors. Finally, competition from lower-cost laminators and from alternative bonding technologies (thermo-compression, adhesive dispensing with out-gassing controls, room-temperature bonding chemistries) places downward pressure on pricing for commodity laminators while rewarding higher-value, higher-yield systems.

Winning suppliers will combine robust vacuum sub-system integration (or secure local pump supply), modular automation that scales from pilot to production, and tight co-development relationships with OSATs and OEM packaging teams to shorten qualification cycles. For customers, procurement strategies that favor staged buys pilot benchtop units followed by modular high-throughput add-ons reduce risk and align CAPEX with validated yield improvements. In ASEAN, local service partners and spare-parts hubs are critical to reduce downtime and to win retrofit/upgrade cycles; suppliers that offer conversion kits or retrofit packages for existing laminators capture an important aftermarket revenue stream. Investors should prioritize equipment vendors with recurring service revenue, strong installed bases in APAC, and component-supply resilience (either through vertical supply or preferred supplier agreements for pumps and motion subsystems).

Product Models

Wafer level vacuum laminators are specialized equipment used in semiconductor packaging, advanced displays, and microelectronics manufacturing. They provide uniform bonding, encapsulation, and protection of wafers or panels by removing trapped air and ensuring defect-free lamination.

Hot Press Vacuum Laminators for high-strength bonding. Notable products include:

SKY Technology Hot-Press Vacuum Laminator SKY Technology: Precision equipment for semiconductor wafer encapsulation.

Nisshinbo Hot-Press Vacuum Laminator Nisshinbo Holdings: Used in high-reliability IC packaging applications.

Toray Engineering Vacuum Hot-Press Laminator Toray Engineering: Applied in flexible displays and OLED panel lamination.

Hanwha Precision Hot-Press Vacuum Laminator Hanwha Precision Machinery: Ensures strong lamination with minimal voids.

Shibaura Mechatronics Vacuum Laminator Shibaura Mechatronics: Designed for semiconductor back-end packaging.

UV Curing Laminators for fast curing of adhesives and films. Examples include:

Toray UV-Curing Laminator Toray Engineering: For flexible electronics and thin-film bonding.

Nisshinbo UV Vacuum Laminator Nisshinbo Holdings: Used in photonics and UV-curable adhesive packaging.

EV Group EVG® UV-Laminator EV Group (EVG): Industry leader in UV nanoimprint and bonding.

SUSS MicroTec UV-Curing Laminator SUSS MicroTec: Precise UV-curing for wafer-level optics packaging.

Hanwha UV Vacuum Laminator Hanwha Precision Machinery: Optimized for high-throughput flexible OLED lamination.

Normal Temperature Laminators for delicate substrates requiring low-heat processing. Notable products include:

SKY Technology Room-Temperature Vacuum Laminator SKY Technology: Used for wafer and flexible substrate encapsulation.

Toray Engineering Low-Temp Laminator Toray Engineering: Applied in flexible OLED and sensor packaging.

Shibaura Normal Temperature Laminator Shibaura Mechatronics: Designed for MEMS and delicate device assembly.

EV Group EVG® RT-Laminator EV Group (EVG): Specializes in low-heat wafer bonding.

SUSS MicroTec Room-Temp Laminator SUSS MicroTec: Ensures high-quality lamination of photosensitive materials.

Wafer-level vacuum laminators are an essential, if niche, capital-equipment class that enables high-yield wafer-level packaging and advanced substrate assembly; using reconciled sources we estimate a 2024 market of about USD 237 million and model a central 5,9% CAGR to 2031 that produces a mid-hundreds-of-millions market by the end of the decade under our base case. Asia-Pacific will remain the primary market for both unit volumes and high-value production systems, while ASEAN (including Indonesia) will be an important unit-volume growth theatre for bench and mid-range tools as regional assembly and OSAT ecosystems expand. Tool vendors that secure vacuum-pump supply chains, offer modular upgrade paths, and maintain strong APAC service footprints will capture the most durable share of the expanding wafer-level packaging demand.

Investor Analysis

What investors should see is exposure to a capital-equipment niche whose demand is mechanically tied to wafer-level packaging and OSAT investments a sector that benefits from secular trends toward heterogeneous integration, miniaturization and fan-out packaging. How investors capture value is by backing equipment OEMs with diversified portfolios (benchtop → production), recurring spares and service streams, or distribution/service businesses that operate retrofit and on-site calibration fleets across APAC/ASEAN. Why this matters now is that wafer-level packaging capacity expansions, supply-chain localization for vacuum components (notably the U.S. CHIPS-era vacuum supply initiatives announced Oct 2024) and panel-level packaging consortia activity are shortening the path from pilot to production for new packaging flows creating a near-term window for equipment vendors to secure multi-line orders and long service contracts. Key diligence items include a vendors installed base and retention rate in APAC, spare-parts margins, component-supply partnerships for pumps and motion stages, and any binding offtake or integration agreements with OSATs and packaging fabs.

Request for Pre-Order Enquiry On This Report

https://www.qyresearch.com/customize/5049009

5 Reasons to Buy This Report

It reconciles specialist equipment trackers and wafer-level packaging demand signals into a defensible 2024 baseline and provides an explicit CAGR scenario that is suitable for investor and procurement modelling.

It translates dollars into practical unit ranges using transparent ASP sensitivity bands, producing implied 2024 unit volumes so capex planners can size buying programs and spare-parts inventories.

It documents dated, material industry signals that materially affect procurement timing and supply risk.

It provides regionally actionable APAC and ASEAN intelligence, linking packaging line expansions and regional assembly moves to likely laminator demand and aftermarket service needs.

It profiles the supplier ecosystem and strategic levers vacuum sub-system resilience, modular automation and service annuities that determine winner economics in a capital-intensive segment.

5 Key Questions Answered

What is a defensible market size for wafer-level vacuum laminators in 2024 and which CAGR should be used to model growth to 2031?

What realistic price-per-unit ranges exist for bench, mid-range and high-throughput wafer laminators and what implied shipment volumes did 2024 represent?

Which dated developments in 20242025 materially reduce supply risk or change tool specifications?

How will APAC and ASEAN differ in unit mix and service requirements for laminators, and what local investments shorten procurement cycles?

Which vendor capabilities best predict durable margins and why should investors prioritize those capabilities?

Chapter Outline

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

Contact Information:

Tel: +1 626 2952 442 (US) ; +86-1082945717 (China)

+62 896 3769 3166 (Whatsapp)

Email: willyanto@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wafer Level Vacuum Laminator Market to Reach USD 355 Million by 2031 Top 10 Company Globally here

News-ID: 4185390 • Views: …

More Releases from QY Research

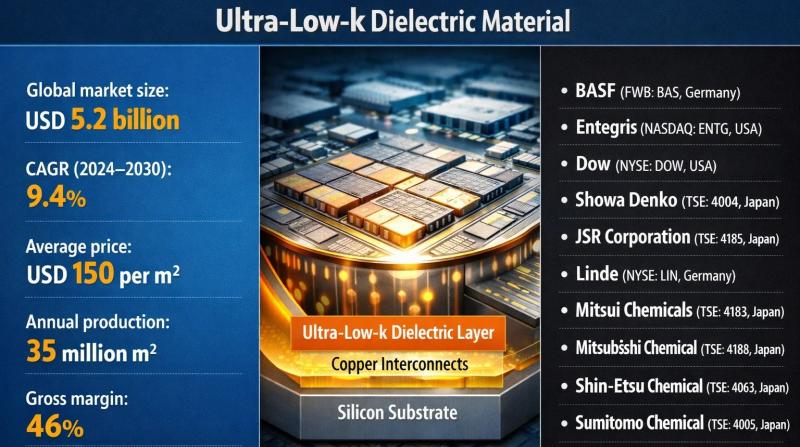

Market Overview - Ultra-low-k Dielectric Material

QY Research has recently published a comprehensive market study on Ultra-low-k Dielectric Material, a critical class of advanced insulating materials engineered to reduce parasitic capacitance and signal delay in advanced semiconductor interconnects. Ultra-low-k dielectrics are essential enablers for sub-7 nm logic nodes, advanced memory, high-performance computing, and AI accelerators, where interconnect RC delay increasingly limits device performance and power efficiency.

The market is transitioning from dense SiO2 and conventional low-k materials…

Global and U.S. Quadruped Mobile Robots Market Report, Published by QY Research.

QY Research has released a comprehensive new market report on Quadruped Mobile Robots, are four-legged robotic systems designed to move and operate in complex, unstructured environments by mimicking the locomotion of animals. They use a combination of advanced sensors, actuators, AI algorithms, and real-time control systems to maintain balance, navigate uneven terrain, climb obstacles, and adapt to dynamic conditions. Because of their high stability and mobility, quadruped robots are widely…

Global and U.S. Industrial Edge Cloud Devices Market Report, Published by QY Res …

QY Research has released a comprehensive new market report on Industrial Edge Cloud Devices, ruggedized computing platforms that bring cloud-native processing, storage, and AI analytics directly to the industrial edge-close to machines, sensors, and control systems. By executing latency-sensitive workloads locally while synchronizing with central or public clouds, these devices enable real-time decision-making, improved reliability, and secure data governance across factories, utilities, energy assets, and transportation infrastructure. As Industry 4.0,…

Top 30 Indonesian Ceramic Public Companies Q3 2025 Revenue & Performance

1) Overall companies performance (Q3 2025 snapshot)

PT Arwana Citramulia Tbk (ARNA)

PT Cahayaputra Asa Keramik Tbk (CAKK)

PT Intikeramik Alamasri Industri Tbk (IKAI)

PT Keramika Indonesia Assosiasi Tbk (KIAS)

PT Mulia Industrindo Tbk (MLIA)

PT Asahimas Flat Glass Tbk (AMFG) (glass & ceramic-adjacent)

PT Niro Ceramic Nasional Indonesia

PT Eleganza Tile Indonesia

PT Roman Ceramic International

PT Platinum Ceramics Industry

PT Granito (Citra Granito)

PT Diamond Keramik Indonesia

PT Indogress (Inti Keramik Sejahtera)

PT Indopenta Sakti Teguh

PT Sun Power Ceramics

PT Satyaraya Keramindo Indah…

More Releases for Laminator

Solventless Laminator for Flexible Packaging Market Summary

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Solventless Laminator for Flexible Packaging- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2026-2032), this report provides a comprehensive analysis of the global Solventless Laminator for Flexible Packaging market, including market size, share, demand, industry development status, and forecasts for…

Best Laminator For 24 Inch Graphics

Top 5 Laminators for 24" Graphics in 2025: Why MF1700 Series Dominates Print Shops?

The graphics industry is rapidly evolving, with new technologies and techniques transforming how printed materials are created and presented. Laminators have become indispensable tools in this field, offering a reliable way to enhance the durability, visual appeal, and overall quality of prints. Whether you're producing signage, posters, or other large-format graphics, choosing the right laminator can make…

Global Tabletop Pouch Laminator Market Insights Analysis 2025-2031

On 2025-2-25 Global Info Research released【Global Tabletop Pouch Laminator Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031】. This report includes an overview of the development of the Tabletop Pouch Laminator industry chain, the market status of Consumer Electronics (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), Household Appliances (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot…

2020 Global Market Analysis on Laminator Industry

The global Laminator market 2020 mainly focuses on the market trend, market share, size and forecast. It is a brief and professional analysis on the current scenario of the Global Laminator market.

The report on Laminator market is a comprehensive study on global market analysis and insights. The report focuses on the emerging trends in the global and regional spaces on all the significant components, such as market capacity, cost, price, demand and supply, production, profit,…

Global Laminator Market Share 2020-2025

Global Laminator Market Overview:

GLOBAL INFO RESEARCH�has evaluated the global Laminator market�in its latest research report. The research report, titled [Global Laminator Market 2020 by Manufacturers, Regions, Type and Application, Forecast to 2025], presents a detailed analysis of the drivers and restraints impacting the overall market. Analysts have studied the key trends defining the trajectory of the market. The research report also includes an assessment of the achievements made by the…

Explore Global Thermal Laminator Market forecast 2019 – 2025

The research report published by QY Research is a comprehensive study of the global Thermal Laminator market. The subject matter experts and team of highly-skilled researchers have put in hours of work to collate an authentic research report on the global Thermal Laminator market. Analysts have studied the various products in the market and offered an unbiased opinion about the factors that likely to drive the market and restrain it.…