Press release

Oil Steel Pipe: Materials, Properties, and Common Sizes - ROYAL GROUP

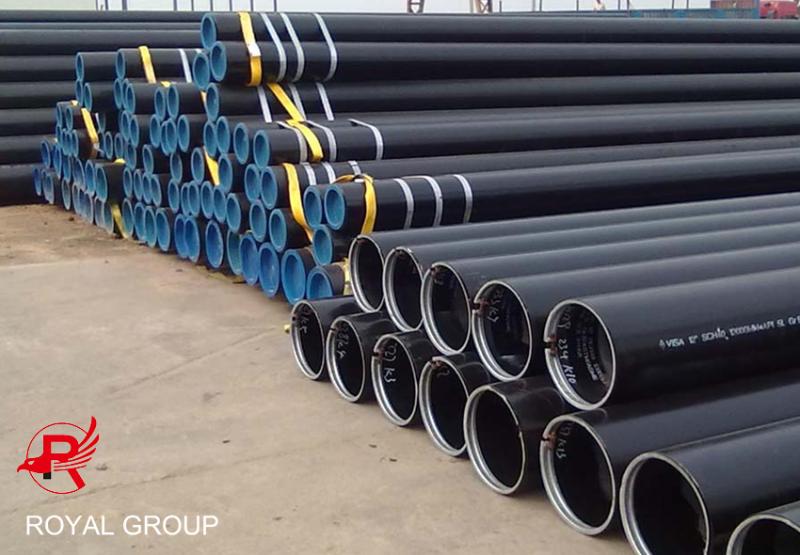

In the vast oil industry, Oil steel pipes play a vital role, serving as a key carrier in the delivery of oil and natural gas from underground extraction to end users. From drilling operations in oil and gas fields to long-distance pipeline transportation, various types of Oil [https://www.royalsteelgroup.com/api-5l-gr-b-astm-a53-a106-carbon-seamless-line-pipe-product/]steel pipes [https://www.royalsteelgroup.com/api-5l-gr-b-astm-a53-a106-carbon-seamless-line-pipe-product/], with their unique materials and properties, ensure the safe and efficient operation of the entire industry chain. This article will focus on carbon steel pipe, seamless steel pipe, and API 5L steel pipe (steel pipe that meets API 5L standards), including typical examples such as API 5L X70 pipe, API 5L X60 pipe, and API 5L X52 pipe, providing a detailed introduction to the materials, properties, and common sizes of Oil steel pipes.Image: https://www.royalsteelgroup.com/uploads/API-5L-Pipe-A-Critical-Pipeline-for-Energy-Transportation.pngMaterial Analysis

1. Carbon Steel Pipe [https://www.royalsteelgroup.com/api-5l-gr-b-astm-a53-a106-carbon-seamless-line-pipe-product/]

Carbon steel pipe is one of the most commonly used materials for Oil steel pipes. It is primarily composed of iron and carbon, with small amounts of manganese, silicon, sulfur, and phosphorus. Carbon content determines the strength and toughness of steel. Generally speaking, higher carbon content increases steel strength, but toughness and weldability decrease. In the oil industry, carbon steel pipe offers excellent overall performance. It not only possesses high strength to withstand the pressures of oil and gas transportation, but also possesses a certain degree of toughness to adapt to complex geological environments. Furthermore, carbon steel pipe is relatively low-cost and offers a high cost-effectiveness, making it widely used in oil and gas pipelines.

2. API 5L Steel Pipe Series Materials

API 5L Steel Pipe is manufactured according to the API 5L standard established by the American Petroleum Institute (API) and is primarily used for oil and gas pipelines. This series of steel pipe is classified into different grades based on the steel's strength, such as X52, X60, and X70. For example, API 5L X52 Pipe is made of high-strength low-alloy steel. In addition to basic elements such as carbon and iron, it also contains alloying elements such as niobium, vanadium, and titanium. The addition of these alloying elements significantly enhances the steel's strength and toughness, while also improving its weldability and corrosion resistance. The material of Api 5l X60 Pipe and Api 5l X70 Pipe is further optimized based on this foundation. By adjusting the alloying element ratio and heat treatment process, the steel's strength and overall performance are further enhanced, enabling it to meet the demands of oil and gas transportation under higher pressures and more complex operating conditions.

3. Seamless Steel Pipe [https://www.royalsteelgroup.com/astm-a16-gr-b-seamless-steel-pipe-product/]

Seamless steel pipe is manufactured through processes such as perforation and pipe rolling. Its material is essentially the same as the aforementioned carbon steel pipe and Api 5l series steel pipe, but the unique nature of its production process gives it unique advantages. Seamless steel pipe has no welds on its wall, resulting in a uniform overall structure and high strength. It can withstand higher pressures and harsher environmental conditions. Therefore, it is commonly used in the oil industry for applications requiring high performance, such as high-pressure oil and gas pipelines and wellheads.

Properties and Characteristics

1. Strength

Strength is a key property of oil pipes, directly impacting their safety during oil and gas transportation. The strength grade of API 5l series steel pipes is indicated by a number following the "X." For example, X52 indicates a minimum yield strength of 52 ksi (kilopounds per square inch), equivalent to approximately 360 MPa in megapascals; X60 has a minimum yield strength of 60 ksi (approximately 414 MPa); and X70 has a minimum yield strength of 70 ksi (approximately 483 MPa). As the strength grade increases, the pressure the pipe can withstand increases accordingly, making it suitable for oil and gas pipelines with varying pressure requirements. Seamless steel pipe, due to its uniform structure and more stable strength distribution, performs better when withstanding high pressures.

2. Corrosion Resistance

Oil and natural gas transportation may contain corrosive media such as hydrogen sulfide and carbon dioxide, so oil pipes must possess a certain level of corrosion resistance. Carbon steel pipe inherently has relatively weak corrosion resistance, but its corrosion resistance can be significantly improved by adding alloying elements (such as chromium and molybdenum in the Api 5l series) and applying surface anti-corrosion treatments (such as coatings and plating). Through appropriate material design and processing, Api 5l X70 Pipe, X60 Pipe, and X52 Pipe, among others, maintain a long service life in corrosive environments.

3. Weldability

During oil pipeline construction, steel pipes must be connected by welding, making weldability a crucial attribute of oil pipeline steel pipe. Api 5l series steel pipe is specifically designed for excellent weldability, ensuring the strength and tightness of welded joints. High-quality welds can also be achieved with carbon steel pipe and seamless steel pipe using appropriate welding techniques.

Image: https://www.royalsteelgroup.com/uploads/Learn-more-about-oil-casing-uses-differences-from-API-pipes-and-features.png Common Sizes

1. Outer Diameter

Oil pipeline steel pipes come in a wide range of outer diameters to meet diverse transportation needs. Common outer diameter sizes for Api 5L series steel pipes include 114.3mm (4 inches), 168.3mm (6.625 inches), 219.1mm (8.625 inches), 273.1mm (10.75 inches), 323.9mm (12.75 inches), 355.6mm (14 inches), 406.4mm (16 inches), 457.2mm (18 inches), 508mm (20 inches), 559mm (22 inches), and 610mm (24 inches). The outer diameter sizes of seamless steel pipes are similar to those of the Api 5L series, but non-standard sizes can also be produced to meet customer needs.

2. Wall Thickness

Wall thickness is a key factor affecting the strength and load-bearing capacity of steel pipes. The wall thickness of petroleum steel pipes varies depending on the pressure rating and application requirements. Taking API 5L X52 pipe as an example, for an outer diameter of 114.3mm, common wall thicknesses include 4.0mm, 4.5mm, and 5.0mm. For an outer diameter of 219.1mm, the wall thickness may be 6.0mm, 7.0mm, or 8.0mm. API 5L X60 and X70 pipes, due to their higher strength requirements, typically have thicker walls than X52 pipes of the same outer diameter to ensure adequate strength and safety. The wall thickness of seamless steel pipe can be precisely controlled based on production processes and customer requirements, ranging from 2mm to several tens of millimeters.

3. Length

The standard length of petroleum steel pipe is generally 6 meters, 12 meters, etc., for ease of transportation and construction. In actual applications, custom lengths can also be produced based on the specific requirements of the pipeline project, reducing on-site cutting and welding workload and improving construction efficiency.

In summary, the material, properties, and conventional dimensions of Oil steel pipes are key factors in their design and application. Carbon Steel Pipe, Seamless Steel Pipe, and steel pipes in the Api 5l Steel Pipe [https://www.royalsteelgroup.com/api-5l-gr-bx42-x52-x60-x65-psl2-carbon-steel-line-pipe-product/] series, such as X70, X60, and X52, each play an important role in different areas of the Oil industry due to their unique advantages. With the continuous development of the Oil industry, the performance and quality requirements for Oil steel pipes are becoming increasingly stringent. In the future, more high-performance Oil steel pipes will be developed and applied to meet the needs of complex working conditions and long-distance, high-pressure transportation.

Contact Us for More Information

Email: sales01@royalsteelgroup.com (Sales Director)

Tel / WhatsApp: +86 153 2001 6383

Factory Contact: +86 199 0219 7728 (Factory Contact)

Media Contact

Company Name: ROYAL GROUP.

Contact Person: Media Relations

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=oil-steel-pipe-materials-properties-and-common-sizes-royal-group]

Phone: +86 153 2001 6383

Country: China

Website: https://www.royalsteelgroup.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Oil Steel Pipe: Materials, Properties, and Common Sizes - ROYAL GROUP here

News-ID: 4159060 • Views: …

More Releases from ABNewswire

Krew Supply Co Builds Competitive Clarity Across Industrial Tooling Markets with …

Krew Supply Co strengthened competitive positioning and procurement conversations across industrial tooling markets using Playwise HQ. By centralising competitor battlecards, objection handling, and field intelligence, the team improved consistency across product categories, responded faster in tenders, and built greater confidence in high-stakes B2B buying environments.

SYDNEY, Australia - 25 February, 2026 - Playwise HQ [https://playwisehq.com/], the AI-native competitive intelligence platform for B2B sales teams, today shared new customer results demonstrating how…

PITAKA Turns the Galaxy S26 Case Into a Programmable Control Hub With Aaron Butt …

Hong Kong, China - 25th Feb, 2026 - PITAKA [https://pitakagermany.com/] today introduces its Galaxy S26 case lineup featuring the Aaron Button, a built-in three-button shortcut system that transforms a traditional phone case into an intelligent hardware interface.

Image: https://www.abnewswire.com/upload/2026/02/c965846dc9c58a7700fa39917f7786c5.jpg

Designed for productivity and customization, Aaron Button allows users to assign programmable shortcuts to physical buttons integrated into the case. With a single press, users can launch apps, trigger smart home routines, activate…

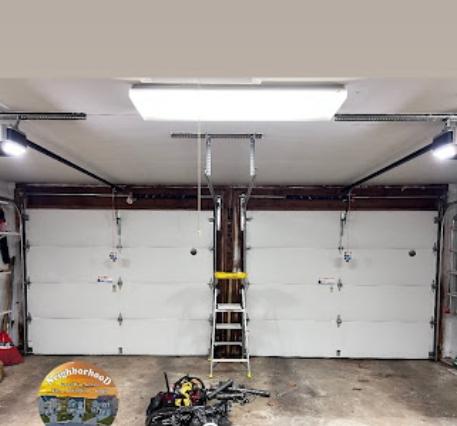

Garage Door Repair Insights Released by Neighborhood Garage Door Repair Of Rockv …

Neighborhood Garage Door Repair Of Rockville continues to serve as a consistent source of garage door support for homeowners and businesses throughout Rockville MD. By maintaining service availability and responding to both routine and urgent repair needs, Neighborhood Garage Door Repair Of Rockville contributes to reliable property access and operational continuity across the local community.

Introduction: Garage Door Repair in Rockville MD

Garage Door Repair [https://www.neighborhood-gds.com/#:~:text=Expert-,garage%20door%20repair,-and%20installation%20services] in Rockville MD remains readily available…

Garage Door Cable Replacement Resource for Rockville MD Homeowners Established b …

Neighborhood Garage Door Repair Of Rockville is a consistent provider of garage door installation and support in Rockville, MD. By maintaining high service availability, the firm ensures homeowners have access to dependable replacement solutions and mechanical maintenance. Their ongoing presence supports regional safety and functional standards, providing the community with reliable, professional options for maintaining secure garage door systems now and in the future.

Introduction: Garage Door Cable Replacement in Rockville…

More Releases for Pipe

How to choose Seamless Pipe vs Welded Pipe vs Spiral Welded Pipe

Seamless pipe, welded pipe, and spiral welded pipe are the three most common types. They may appear similar in appearance, but the differences are profound in essence, with the core distinction indeed stemming from manufacturing processes.

Comparison Table

FEATURE DIMENSION

SEAMLESS STEEL PIPE

LONGITUDINALLY WELDED PIPE

SPIRAL WELDED PIPE

Manufacturing Process

Solid billet piercing and rolling, no weld seam.

Steel plate/sheet is curved and welded along a longitudinal straight seam.

Steel strip is coiled at a spiral angle, forming…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…