Press release

High Heat Foam Market is Expected to Reach a Valuation of USD 29.7 billion by 2035 | FactMR Report

The global high heat foam market is forecast to reach USD 29.7 billion by 2035, up from USD 13.4 billion in 2025, advancing at a compound annual growth rate (CAGR) of 8.3% during the forecast period. This growth is being driven by increasing demand across aerospace, automotive, and electronics industries, particularly due to the lightweight yet high-temperature-stable properties of these foams.For More Insights into the Market, Request a Sample of this Report: https://www.factmr.com/connectus/sample?flag=S&rep_id=7496

Segmentation by Type

In terms of product types, the market is segmented into Polyurethane (PU) Foam, Polyimide Foam, Melamine Foam, Polystyrene Foam (EPS/XPS), Silicone Foam, and other specialty foams. Among these, Polyurethane Foam is expected to maintain its dominance as it provides an effective balance of lightweight construction, durability, and cost efficiency. Melamine and Polyimide foams are gaining ground in applications where superior heat resistance is required, while Silicone foams are widely chosen for their excellent flexibility and sealing performance. Polystyrene foams, both EPS and XPS, continue to be integral in insulation solutions, especially within the construction industry.

Segmentation by Application

The high heat foam market serves a wide range of applications, including thermal insulation, acoustic insulation, sealing and gasketing, cushioning and vibration damping, pipe and duct insulation, and fireproofing. Thermal insulation remains the most significant application area, largely driven by the automotive and electronics industries where maintaining stable operating conditions is essential. Acoustic insulation is becoming increasingly important with the need to enhance comfort in vehicles, aircraft, and residential spaces.

Sealing and gasketing applications rely on foams for their ability to withstand both high pressure and temperature fluctuations. Cushioning and vibration damping are also crucial, particularly in transportation and industrial machinery, where vibration control enhances both safety and efficiency. Furthermore, pipe and duct insulation, as well as fireproofing, highlight the critical role of high heat foams in construction and safety systems.

Segmentation by End-Use Industry

The end-use industries for high heat foam are diverse, reflecting the versatility of these materials. In the automotive and transportation sector, the increasing adoption of electric vehicles is creating higher demand for lightweight, thermally stable foams that can be used in battery insulation, dashboards, and seating systems. The aerospace and defense industry requires high-performance insulation and fireproofing solutions, making foams an essential component in aircraft interiors and safety systems. In the electronics and electrical sector, the need for thermal management is rising rapidly as devices and infrastructure become more advanced, particularly with the rollout of 5G and high-performance computing systems.

The building and construction industry continues to rely heavily on foams for energy-efficient insulation and fire protection. Industrial manufacturing incorporates foams for sealing, vibration control, and equipment protection. Consumer appliances, ranging from ovens to refrigerators, depend on high heat foams for both insulation and durability. The marine and offshore industry also benefits from these materials, utilizing them in insulation and safety applications in environments exposed to harsh operating conditions.

Buy Report - Instant Access: https://www.factmr.com/checkout/7496

Recent Market Developments and Competitor Insights

The high heat foam market is highly competitive, with a mix of global corporations and specialized players working to expand their market presence. Companies such as BASF SE, Rogers Corporation, Dow, Evonik Industries, Huntsman, Saint-Gobain, Armacell, Wacker Chemie AG, and Morgan Advanced Materials are among the prominent leaders shaping the industry. Their strategies range from expanding production capacity to introducing innovative product lines tailored to the growing needs of end-use sectors.

Recent developments indicate a strong focus on sustainability and the circular economy. Many producers are moving toward bio-based raw materials and recyclable foam structures that meet stricter environmental regulations while maintaining performance. Innovation is also targeting electric vehicles, where foams are increasingly used to provide lightweight solutions that improve thermal management and extend battery life. Aerospace applications continue to drive the demand for advanced fireproof and vibration-damping foams, while construction markets emphasize fire resistance and energy efficiency.

Regional dynamics also play an important role in shaping the competitive landscape. Asia-Pacific, particularly China and India, has emerged as a high-growth hub thanks to rapid industrialization, rising automotive production, and expanding infrastructure development. Meanwhile, North America and Europe remain innovation leaders, with companies investing heavily in R&D to develop high-performance foams aligned with strict regulatory frameworks.

Several companies have taken notable strategic steps in recent years. Dow has expanded its production facilities and introduced new foam products with enhanced fire resistance, while also advancing sustainability efforts. Saint-Gobain has been channeling significant investments into research and development to create advanced foams for both construction and transportation applications. Armacell and Evonik Industries are focusing on expanding their product portfolios and strengthening their positions in specialty foams with high resistance to extreme conditions.

Browse Full Report: https://www.factmr.com/report/high-heat-foam-market

Forecast Summary

The growth outlook for high heat foams is robust. The global market is expected to reach USD 29.7 billion by 2035, up from USD 13.4 billion in 2025, registering a CAGR of 8.3%. This expansion is underpinned by the increasing use of lightweight and high-temperature-resistant foams across aerospace, automotive, and electronics industries. The growing emphasis on energy efficiency, sustainability, and safety standards across multiple sectors further solidifies the role of high heat foams as essential materials for modern applications.

Check out More Related Studies Published by Fact.MR Research:

Triisostearyl Citrate Market: https://www.factmr.com/report/3198/triisostearyl-citrate-market

Metal Powder Market: https://www.factmr.com/report/3202/metal-powder-market

Nanoporous Materials Market: https://www.factmr.com/report/3204/nanoporous-mnanoporous-materials-market

Brightness Enhancement Films Market: https://www.factmr.com/report/3207/brightness-enhancement-films-market

Contact:

US Sales Office:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

Sales Team : sales@factmr.com

About Us:

Fact.MR is a distinguished market research company renowned for its comprehensive market reports and invaluable business insights. As a prominent player in business intelligence, we deliver deep analysis, uncovering market trends, growth paths, and competitive landscapes. Renowned for its commitment to accuracy and reliability, we empower businesses with crucial data and strategic recommendations, facilitating informed decision-making and enhancing market positioning.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release High Heat Foam Market is Expected to Reach a Valuation of USD 29.7 billion by 2035 | FactMR Report here

News-ID: 4155785 • Views: …

More Releases from Fact.MR

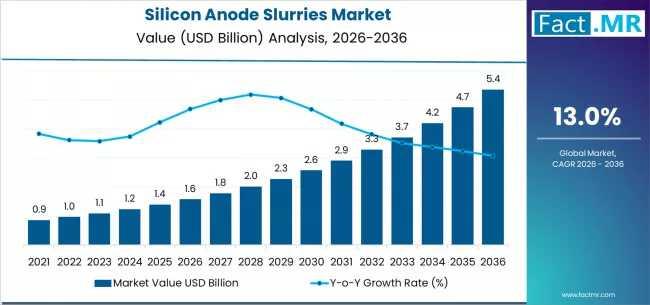

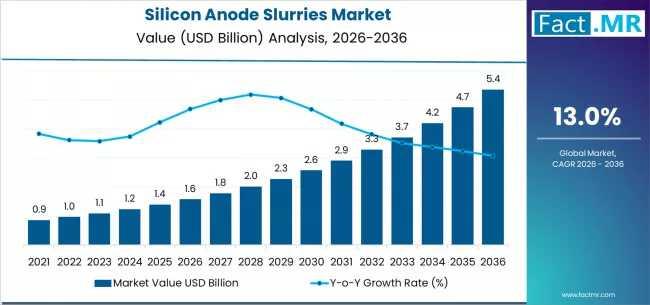

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

Silicon Anode Slurries Market Forecast 2026-2036: Market Size, Share, Competitiv …

The global silicon anode slurries market is set for significant expansion between 2026 and 2036, fueled by the rising adoption of high-energy-density lithium-ion batteries across electric vehicles (EVs), consumer electronics, and grid-scale energy storage. As battery manufacturers increasingly transition from graphite to silicon-enhanced anodes, the demand for high-performance, scalable silicon anode slurries is projected to grow sharply.

To access the complete data tables and in-depth insights, request a Discount On The…

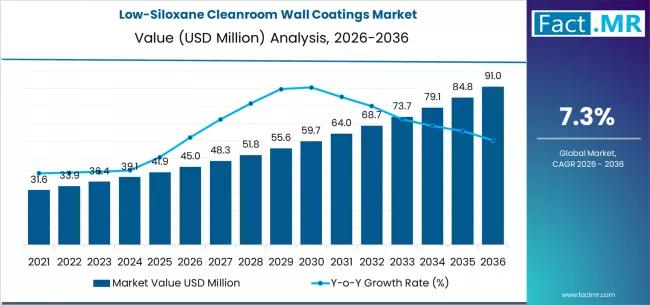

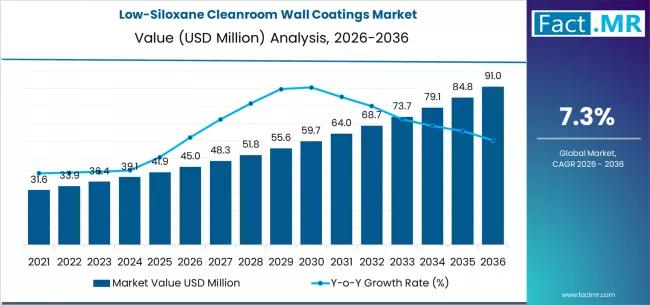

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

Low-Siloxane Cleanroom Wall Coatings Market Deep-Dive 2026-2036: Strategic Forec …

The low-siloxane cleanroom wall coatings market is poised for steady growth over the next decade, driven by rising contamination-control requirements across semiconductor, pharmaceutical, biotechnology, and precision manufacturing industries. These coatings are specifically engineered to minimize siloxane outgassing and volatile organic compound emissions, helping maintain ultra-clean environments where even trace contamination can disrupt production quality.

By 2036, the market for low-siloxane cleanroom wall coatings is expected to grow to USD 91.04 million.…

More Releases for Foam

Foam Concentrate Market: High-growth Regions to Expand Geographic Footprint | Ch …

"This research study presents a comprehensive compilation of insightful findings concerning key aspects of the global Foam Concentrate industry, impacting its growth trajectory over the forecast period from 2023 to 2029. The report sheds light on the evolving sales trends of various tech products across different regions and countries, highlighting both growth and decline. A detailed regional analysis is a crucial part of this Foam Concentrate report, offering a meticulous…

Packaging Foams Market Report with Forecast 2020-2025 | Top Key Players: BASF, A …

Global Packaging Foams market would thus note a steady growth over the forecast period of 2020 - 2025. The robust CAGR (Compound Annual Rate Growth) will chart an upward growth curve and create lucrative growth opportunities in the global Packaging Foams market. In, turn, this will lead to improvement in market worth.

Request a PDF sample of this report: https://www.adroitmarketresearch.com/contacts/request-sample/1415

Global Packaging Foams Market: Notable Development

Global Packaging Foams market is set to…

Technical Foam Services Develops Innovative New Scaffold Foam

Northamptonshire, United Kingdom (8th February, 2013) - Technical Foam Services Ltd, a leading independent engineer-based manufacturer and foam producer, announces the creation of a new scaffold foam.

Technical Foam Services Ltd and their strategic construction partner have been working in unison to develop the Closed Cell PE Scaffold Foam, which uses high density polyethylene foam to offer protection against work equipment damage to decorated surfaces. The scaffold foam also uses a…

Technical Foam Services Creates Foam Inserts for Rak Ceramics

Northamptonshire, United Kingdom (18th February, 2013) - Technical Foam Services Ltd, a leading independent engineering-based manufacturer and foam producer, earlier this month secured a contract with leading ceramic tile design and manufacturer Rak Ceramics.

Rak Ceramics specialises in offering a range of high-quality ceramic tiles, distributing their products to DIY retailers and kitchen designers nationwide.

Sales representatives from the company were becoming increasingly concerned with the loss and damage of these tiles…

Technical Foam Services Manufactures Cancer Prevention Foam

Northamptonshire, United Kingdom (17 June, 2011) - Technical Foam Services, a leading independent engineering-based manufacturer and foam producer, is proud to have been part of an exciting new development in the world of cancer prevention.

A far cheaper and more patient-friendly method has been developed by the UK Medical Research Council, which involves the use of a reticulated foam sponge encapsulated within a pill. Once the pill is swallowed, it dissolves…

Technical Foam Services Expand Range of Foam Insert Fabrics

Northamptonshire, United Kingdom (19th May, 2011) – Technical Foam Services, a leading independent engineering-biased manufacturer and foam producer, has expanded their range of fabrics to be used with foam inserts.

Technical Foam Services have long been recognised as the UK’s leading supplier of foam inserts, producing them for a wide variety of applications, such as large suitcase inserts suitable for holding ceramics and glassware through to small inserts used…