Press release

CRP USA to Exhibit at Small Satellite Conference 2025

CRP USA will exhibit at the 39th Small Satellite Conference, August 11-13, 2025, at the Salt Palace Convention Center in Salt Lake City (booth #328). The team will showcase flight-ready components for space applications, manufactured using Selective Laser Sintering (SLS) and Windform® composite materials, known for their strength, reliability, and performance in orbit.Salt Lake City, Utah - August 2025 - CRP USA will participate as an exhibitor at the 39th edition of the Small Satellite Conference, to be held August 11-13, 2025, at the Salt Palace Convention Center in Salt Lake City, Utah. This year's theme, "Reaching New Horizons", reflects the innovative spirit that defines CRP USA's approach to additive manufacturing for small satellite development. The company will be exhibiting at booth #328.

At the event, CRP USA will showcase real 3D printed components designed for space applications, manufactured using the Selective Laser Sintering (SLS) process and Windform® composite materials. These cutting-edge materials, originally developed by CRP Technology in Italy, are carbon or glass fiber-reinforced thermoplastics, offering outstanding mechanical strength, thermal resistance, and dimensional stability - all critical properties for space-bound hardware.

Windform materials have been successfully employed in a variety of small satellite applications, including:

• structural panels and enclosures

• antenna and payload supports

• deployable systems

• CubeSat components

All Windform materials used in space applications have passed outgassing tests in accordance with major space agency requirements, confirming their suitability for use in orbit.

"SmallSat continues to be one of the most important venues for meeting face-to-face with the aerospace community," said Chris Brewster, CEO of CRP USA. "We're proud to return and share how Windform and SLS are enabling our customers to move faster, innovate smarter, and deliver reliable parts ready for the final frontier."

"Our customers in the small satellite industry rely on us for more than just parts - they depend on us for speed, quality, and technical insight," added Vu Mai, Senior Director of Sales at CRP USA. "At booth #328, we'll be showcasing new success stories and parts that demonstrate how additive manufacturing in Windorm can truly change the game."

Who: CRP USA

What: Exhibiting at the 39th Small Satellite Conference

When: August 11-13, 2025

Where: Salt Palace Convention Center, Salt Lake City, Utah - Booth #328

Why: To showcase advanced 3D printed solutions for the small satellite industry using Windform® materials and SLS

CRP USA LLC

127 Goodwin Circle

Mooresville, NC 28115 USA

Veronica Negrelli

pressoffice@crp-group.com

via Cesare Della Chiesa, 21

41126 Modena

ITALY

CRP USA specializes in advanced additive manufacturing using the Selective Laser Sintering (SLS) process and Windform® composite materials, developed by CRP Technology in Italy. Based in Mooresville, North Carolina, CRP USA serves the aerospace, defense, and high-tech sectors with high-performance, functional parts for demanding applications, including flight-ready components for small satellites. The company offers AS9100D-certified services, combining technical expertise, fast lead times, and proven material performance to support innovation from prototype to launch.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CRP USA to Exhibit at Small Satellite Conference 2025 here

News-ID: 4136997 • Views: …

More Releases from CRP USA LLC

CRP USA Announces the Appointment of Rom Quintos as New Director of Sales

CRP USA, a leader in advanced 3D printing services and additive manufacturing technologies, is excited to welcome Rom Quintos as its new Director of Sales. With over 20 years of experience in high-tech industries, including aerospace, defense, and semiconductor markets, Rom is well-equipped to drive CRP USA's sales strategy and strengthen the company's position in key sectors.

Rom Quintos brings a wealth of expertise in sales and commercial leadership, having developed…

CRP USA Elevates Wheelchair Racing Gear for Paralympics Champion Tatyana McFadde …

Wheelchair racing demands exceptional performance from athletes due to the high friction generated by constant hand-wheel contact. Traditional gloves often fail to meet the standards required by athletes like Tatyana McFadden, an 8-time Paralympics Gold medallist. Before adopting CRP USA's solution, Tatyana used standard mould kits for her gloves, finding the quality inadequate.

Conventional methods struggled to produce gloves that could withstand the intense stress of wheelchair racing while maintaining…

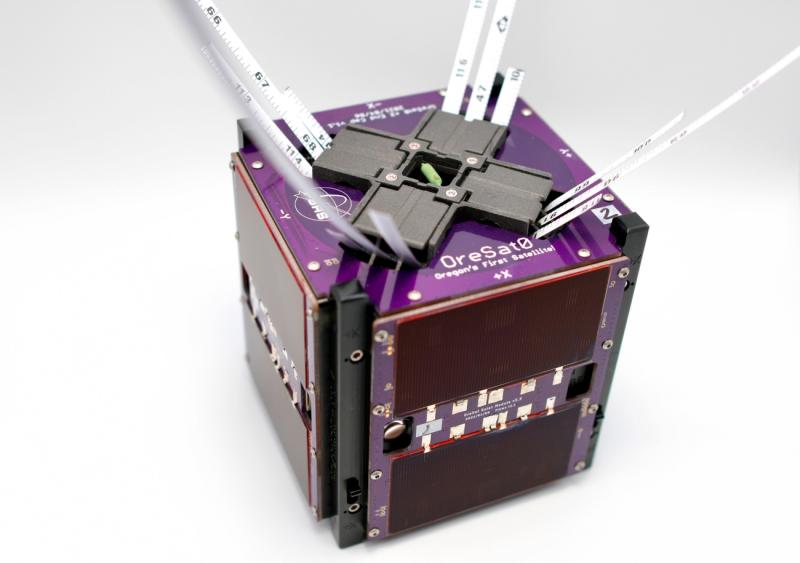

3D printing in Space: Laser sintering process and composite material helped Port …

Kilogram-class satellites, like CubeSats, now have functionality that were only available in larger 100 to 1,000 kg class satellites. Recently, 3D printing has helped speed up this revolution, especially in universities.

CubeSats have been launched by dozens of countries, universities and companies all around the world. And the state of Oregon joined them recently thanks to the Portland State Aerospace Society (PSAS) that built OreSat0, their very own artisanally hand-crafted…

How professional 3D printing and Carbon fiber filled composites help Formula SAE …

The CRP USA and UVic Formula Racing partnership have created across the years many functional parts in Carbon fiber filled composite materials and Laser Sintering as manufacturing process. These components distinguish for versatility, mechanical properties and durability

The versatility and mechanical properties of the functional components made in Windform materials are well recognized by specialists and insiders. One of the latest examples comes from the world of Formula SAE.

Luke Wooldridge,…

More Releases for Windform

Excellent Electrical Insulation Performance for Windform Composites

3D printing service bureau CRP Technology's Glass fiber reinforced Windform thermoplastic composites were subjected to dielectric constant and dielectric strength tests, and the results were excellent, exhibiting a dielectric constant of approximately 4 and withstanding peak voltages of at least 2.5 kV/mm.

3D printing service bureau CRP Technology is pleased to inform that their Glass fiber reinforced Windform thermoplastic composites for Selective Laser Sintering, have demonstrated outstanding electrical insulation performance as…

Windform RS and Windform LX 3.0 officially approved for space flight

Carbon fiber reinforced composite Windform RS and Glass fiber reinforced composite Windform LX 3.0 from CRP Technology's Windform TOP-LINE, passed ESA standard screening outgassing tests in accordance with ESA-TEC-PR-002015 (based on ECSS-Q-ST-70-02C): they are officially approved for the construction of applications to launch into Space.

Franco Cevolini, CEO and Technical Director of CRP Technology, says: "Passing the outgassing tests is a crucial factor for those who supply materials to the…

Windform® RS, the outstanding composite material with amazing mechanical proper …

CRP Technology launches a new polyamide-based Carbon fiber filled composite for production-grade PBF 3D printing: the top-of-the-range Windform® RS. Engineer Franco Cevolini, CEO and CTO, CRP Technology: "In the Additive Manufacturing world Windform® RS is unparalleled. We created a material that combines high tensile strength with high elongation at break and low density: Windform® RS is unique of its kind"

CRP Technology, a leading 3D printing company, announces the…

3D printed satellite deployer in Windform XT 2.0 acclaimed for its mechanical fe …

Recently Alba Orbital’s AlbaPod V2 hyped up for its unique design, lightweight, easily integration into space launch vehicles, maintenance of the demanding quality standards for space. These characteristics have also made possible thanks to the use of AM and Windform XT 2.0 Carbon composite material

The European Space Agency (ESA) dedicated an article on Alba Orbital's cutting edge 3D printed satellite dispenser, AlbaPod V2, manufactured by CRP Technology using laser sintering…

CRP Windform FR2, new cutting-edge composite material for Additive Manufacturing

CRP Technology, the long-standing leading company in the field of advanced technologies and professional 3D printing, launches on the market a flame-retardant glass fiber reinforced material for Selective Laser Sintering

CRP Technology's hi-tech advancement is unstoppable. Less than six months after the launch on the market of Windform FR1, the first carbon fiber-reinforced flame-retardant material for professional 3D printing, CRP Technology is presenting a new composite material from the TOP-LINE family…

CRP Technology launches Windform® P2, thermoplastic glass fiber filled material …

CRP Technology, a leading company in the creation of prototypes and final applications in professional 3D printing, launches Windform® P2 material.

Windform® P2 is a glass fiber reinforced thermoplastic polyamide material with excellent mechanical properties for High Speed Sintering process.

Engineer Franco Cevolini, CRP Technology CTO and VP, states: “Windform® P2 is the second polymer from P-LINE, the new Windform® range of materials for high speed production-grade 3D printing, introduced on the…