Press release

CRP USA Elevates Wheelchair Racing Gear for Paralympics Champion Tatyana McFadden

Wheelchair racing demands exceptional performance from athletes due to the high friction generated by constant hand-wheel contact. Traditional gloves often fail to meet the standards required by athletes like Tatyana McFadden, an 8-time Paralympics Gold medallist. Before adopting CRP USA's solution, Tatyana used standard mould kits for her gloves, finding the quality inadequate.Conventional methods struggled to produce gloves that could withstand the intense stress of wheelchair racing while maintaining precision and comfort.

Tatyana recalls, "My first wheelchair racing gloves were called 'harness gloves'. They were shaped like thumbs and made of heavy-duty fabric with rubber padding. Their softness made me feel the impact every time I hit the hand ring.

By the 2008 Paralympic Games, my team and I began making hard gloves. We would take plastic beads, melt them in a pot of boiling water, and then mould the plastic to my hands. This process took days to perfect. Sometimes we would have to start over and throw the whole plastic glove back in the water. Once perfected, I did not let the gloves out of my sight because they would melt if left in the car or in the heat for too long. Over time, the plastic would wear down, so we made the gloves thick, but they were heavy." Even these gloves were not up to Tatyana's needs for the highest sporting level.

In 2015, a significant change occurred when Tatyana had the opportunity to experiment with 3D-printed gloves. In 2016, Tatyana connected with CRP USA to continue developing 3D printing racing gloves, aiming for them to be "stronger and more durable" compared to what they were using in 2015. "After a friend of mine told me about CRP USA," Tatyana adds, "I reached out to them and shared my story. I was so excited when I met everyone in person. They are an incredible partner and have really helped me so much. Not just in their innovation but the confidence they gave me since I do not have to worry about the performance of my racing gloves." Tatyana explained that the CRP USA team helped bring her vision for the current gloves to life, making the vision a reality.

Strength and durability were undoubtedly important characteristics that Tatyana required from CRP USA to compete at her best, but they were not the only ones. Lightness, stiffness, resistance to wear and tear, and resistance to weather were other important features Tatyana wanted for her new gloves. "When I met with the CRP USA team," she specifies, "we also talked about heat, rubber, weather effects, and straps for the gloves so they can stay in my hands better. When competing outside, we face various weather conditions, and I want to be ready for anything. My gloves have cracked in the past. My strokes produce a lot of force when I hit the hand ring, and my previous gloves lasted less than a year. I also wanted a better way to add rubber to the hand rings. The CRP USA team listened to my needs and managed to satisfy them in the best possible way."

Before the construction of the parts, discussions with customers are essential to understand their needs in order to satisfy them as best as possible. After several meetings with Tatyana, the CRP USA team opted for Laser Sintering technology and Windform XT 2.0 as the manufacturing material. This solution was selected as the best one to address Tatyana's everyday challenges. In this specific case, the rubber used in the 3D printed gloves is a standard off-the-shelf item. The CRP USA team trims it to size and bonds it to the gloves using a structural adhesive. This operation demonstrates the high professionalism of the CRP USA team and the compatibility of Windform XT 2.0 with various components, ensuring seamless bonding without any issues.

Nathan "Nate" Baker, Senior Project Coordinator at CRP USA, explains, "Throughout her career, Tatyana found that the quality and detail of her gloves were just not up to the high standard she needed. That's when the Windform range of composites for 3D printing, created by our Italian partner CRP Technology, came into play. At CRP USA, we have tried several different Windform materials for her, with the gold standard becoming Windform XT 2.0."

Windform XT 2.0 is known for its superior mechanical properties. These properties ensured the gloves could withstand the constant, high-friction environment of wheelchair racing without deterioration. This durability significantly extended the lifespan of the gloves compared to traditional materials. Additionally, the flexibility and shock-absorbing properties of Windform XT 2.0 ensured maximum comfort, allowing Tatyana to focus solely on her performance without discomfort or distraction.

Here are some of the technical properties of Windform XT 2.0:

• Melting point: 179.3° C / 355° F

• Density (20° C/68° F): 1.097 g/cc

• Tensile strength: 83.84 MPa / 12,200 psi

• Tensile modulus: 8,928.20 MPa / 1,290 ksi

• Heat Deflection Temperature (HDT; 1.82 MPa): 173.4° C / 344° F

• Elongation at break: 3.80%

(Note: The first unit is in the SI system, and the second is in the US customary system; with a period as a decimal separator.)

CRP USA hollowed the parts out and inserted an internal structuring. This allowed a reduction in the weight of the gloves while maintaining strength, integrity, and improving durability. This was a significant contribution to Tatyana's agility and speed during races. The weight reduction was indeed substantial, with the resulting 3D printed gloves in Windform XT 2.0 weighing approximately 100 grams, a 50% reduction from traditional gloves. Once completed, the 3D printed wheelchair racing gloves in Windform XT 2.0 underwent testing for weight and durability, and the results were excellent.

Tatyana was very satisfied with the outcome: "I remember using the gloves in Windform XT 2.0 for the very first time on the track and on the road," she says. "I was so impressed by how light and durable they were. My hands felt so light, it felt like I wasn't holding onto anything. When I first put my hands into the glove, it was so smooth. They had also built in two holes where I could strap on the gloves to my hands instead of using additional clips."

CRP USA and Tatyana continue to collaborate to enhance the 3D printed wheelchair racing gloves, focusing on improving grip and comfort, especially when competing in the rain. This ongoing partnership ensures that Tatyana always has access to the latest advancements in additive manufacturing technology, allowing her to maintain her competitive edge. As Tatyana emphasizes, "CRP USA team keeps finding ways to make the gloves even better. Together, we continuously strive to improve my performance."

crp-usa.net

windform.com

About Tatyana McFadden:

Tatyana McFadden is a Paralympic champion with 20 medals, including eight golds, and 24 World Major Marathon wins. She is known for her relentless pursuit of excellence and is currently training for the Paris Paralympics 2024. On June she is the new American record holder in the 400m

Veronica Negrelli

Press Office Manager CRP USA

127 Goodwin Circle

Mooresville, NC 28115

USA

CRP USA specializes in advanced 3D printing and manufacturing solutions with Windform rage of high-performance composite materials. The company collaborates with athletes and various industries to create innovative, customized solutions that meet the most demanding requirements.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release CRP USA Elevates Wheelchair Racing Gear for Paralympics Champion Tatyana McFadden here

News-ID: 3584228 • Views: …

More Releases from CRP USA LLC

CRP USA to Exhibit at Small Satellite Conference 2025

CRP USA will exhibit at the 39th Small Satellite Conference, August 11-13, 2025, at the Salt Palace Convention Center in Salt Lake City (booth #328). The team will showcase flight-ready components for space applications, manufactured using Selective Laser Sintering (SLS) and Windform® composite materials, known for their strength, reliability, and performance in orbit.

Salt Lake City, Utah - August 2025 - CRP USA will participate as an exhibitor at the 39th…

CRP USA Announces the Appointment of Rom Quintos as New Director of Sales

CRP USA, a leader in advanced 3D printing services and additive manufacturing technologies, is excited to welcome Rom Quintos as its new Director of Sales. With over 20 years of experience in high-tech industries, including aerospace, defense, and semiconductor markets, Rom is well-equipped to drive CRP USA's sales strategy and strengthen the company's position in key sectors.

Rom Quintos brings a wealth of expertise in sales and commercial leadership, having developed…

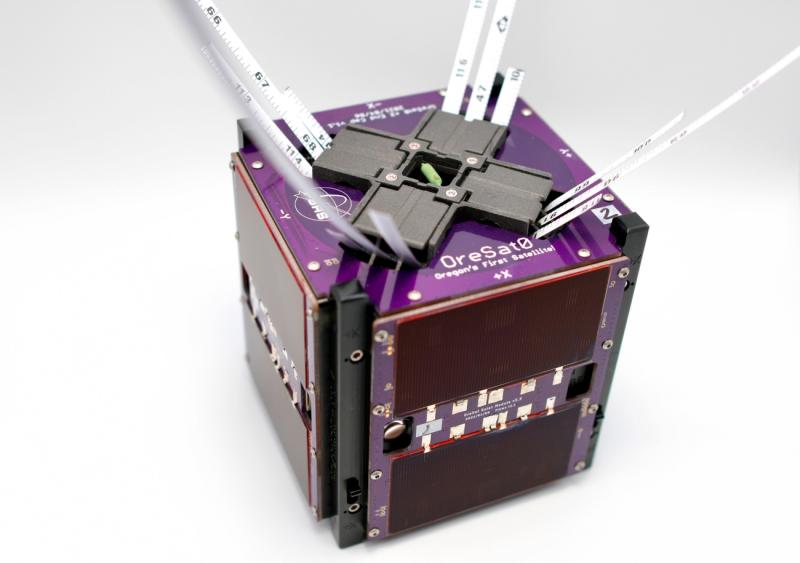

3D printing in Space: Laser sintering process and composite material helped Port …

Kilogram-class satellites, like CubeSats, now have functionality that were only available in larger 100 to 1,000 kg class satellites. Recently, 3D printing has helped speed up this revolution, especially in universities.

CubeSats have been launched by dozens of countries, universities and companies all around the world. And the state of Oregon joined them recently thanks to the Portland State Aerospace Society (PSAS) that built OreSat0, their very own artisanally hand-crafted…

How professional 3D printing and Carbon fiber filled composites help Formula SAE …

The CRP USA and UVic Formula Racing partnership have created across the years many functional parts in Carbon fiber filled composite materials and Laser Sintering as manufacturing process. These components distinguish for versatility, mechanical properties and durability

The versatility and mechanical properties of the functional components made in Windform materials are well recognized by specialists and insiders. One of the latest examples comes from the world of Formula SAE.

Luke Wooldridge,…

More Releases for Tatyana

TATYANA MOSHCHENKOV NAMED PRESIDENT OF OPERATIONS OF WORLD CLASS DIGITAL MARKETI …

One of the world's fastest-growing digital marketing agencies, Jeremy McGilvrey, doesn't attribute their meteoric rise to their half-million in client revenue from Upwork, over 700+ 5-star reviews, or even being consistently featured on publications such as Forbes, and The Huffington Post.

In fact, while their ability to generate ROI-producing, conversion-focused sales funnels and websites that make an incredible first impression and attract high-quality leads is second to none -…

Tatyana Moshchenkov - 5 Common Online Business Models Simplified

Tatyana Moshchenkov (Business Consultant & Strategist) - Most beginners who are new to online marketing tend to get overwhelmed by the sheer number of ways one can make money online. Unfortunately, all money-making methods are NOT made equal.

Survey sites, performing microtasks for pennies, etc. are mostly a waste of time and effort. Whereas other methods such as affiliate marketing, arbitrage, product creation, etc. are very lucrative.

Knowing which business model to…

Tatyana Moshchenkov - What Do You REALLY Need to Build a Successful Online Busin …

Tatyana Moshchenkov is a Business Consultant & Strategist - As per Tatyana "Building, an online business can seem like a convoluted and arduous process." There are so many moving parts and you need to get them all in alignment and running smoothly to start generating profits.

While there is some truth to the scenario mentioned above, the truth is that to build a successful online business requires only 5 components.…

Tatyana Moshchenkov shared tips for creating the website of your dreams

Have you always wanted to design a website but never known where to start? Do you want to get your business online, but can't afford to hire someone to help? This article will be a great start for you, as it contains many great ideas to aid you in creating the website of your dreams!

Use ALT tags whenever possible. These helpful tags describe an image to a viewer, assisting the…

Learn With Tatyana Moshchenkov How To Use Newsletters to Jack Up Revenues

The main use of a newsletter is to distribute information to your readers about your site including product announcements, site updates, news, and more. For business or affiliate websites the newsletter becomes a tool to remind your visitors about your site in order to bring them back or make a sale.

Returning visitors are more focused on what your site has to offer. Also, the more your visitors come back,…

Tatyana Moshchenkov - Is email still a reliable vehicle to deliver your marketin …

"Permission Email Marketing", is the only way to market your business via Email without getting yourself into trouble and giving you the ability to stay in touch and build an ongoing relationship with your customers and subscribers.

The only question is... is email still a reliable vehicle to deliver your marketing messages to your potential customers and/or subscribers?

With the rising concerns of SPAM, Blacklisting, Email Filters, and CAN-SPAM laws, it's getting…