Press release

Global Industrial Non-Contact Vibration Measurement Devices Market to Reach $1,784 Million by 2031

According to the recent report by QYResearch, the global Industrial Non-Contact Vibration Measurement Devices market is projected to grow significantly, reaching an estimated $1.784 billion by 2031, from $862 million in 2024. This growth represents a Compound Annual Growth Rate (CAGR) of 11.0% from 2025 to 2031. This surge is driven by advancements in sensor technologies, increasing demand for predictive maintenance solutions, and the expansion of industrial automation systems.Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)https://www.qyresearch.com/sample/4800529

Leading Companies in the Market

The market is dominated by several key players, including:

• Polytec

• Omron

• SKF

• Keyence

• National Instruments

• Rion Co. Ltd.

• OptoMET GmbH

• Ometron

• Smartec SA

• Ono Sokki

These companies are pioneering innovations in laser Doppler vibrometers, optical interferometric vibration meters, and portable non-contact vibration meters. Polytec, in particular, is leading the 2024 sales figures in this market segment.

Five key Industrial Non-Contact Vibration Measurement Devices

1. Polytec - OFV-5000 Modular Vibrometer Controller

• Type: Laser Doppler Vibrometer

• Function: Non-contact vibration measurement for microstructures, MEMS, acoustics, etc.

• Key Features:

o Modular design compatible with various sensor heads

o Frequency range expandable up to 24 MHz

o High accuracy and excellent signal-to-noise ratio

• Applications: Automotive components, electronics manufacturing, material testing

2. Omron - Vibration Sensor with IO-Link (Model: D7S Series)

• Type: Micro MEMS seismic/vibration detection sensor

• Function: Enables remote, non-contact vibration detection integrated with IO-Link systems

• Key Features:

o Real-time vibration threshold monitoring

o Easy integration into automation systems

o High reliability with strong resistance to electrical noise

• Applications: Equipment condition monitoring, smart factories, predictive maintenance

3. SKF - Machine Condition Advisor CMAS 100-SL (with laser mode)

• Type: Portable non-contact vibration analyzer

• Function: Combines vibration and temperature monitoring with laser-assisted alignment

• Key Features:

o Quickly detects bearing and machine faults

o LED status indicators with digital display

o Rugged design for maintenance teams

• Applications: Power plants, petrochemical facilities, mechanical equipment inspection

4. Keyence - VK-X3000 Series 3D Laser Scanning Confocal Microscope

• Type: Laser confocal system for micro vibration analysis

• Function: Non-contact 3D surface profiling and vibration detection at the nanoscale

• Key Features:

o Capable of measuring transparent, mirrored, and complex surfaces

o High-speed laser scanning head

o Combined 3D and vibration data output

• Applications: Semiconductor analysis, precision parts inspection, materials science

5. Rion - UV-16/UV-15 Laser Doppler Vibrometer

• Type: Laser Doppler-type non-contact vibrometer

• Function: High-sensitivity measurement of vibration velocity and displacement

• Key Features:

o High-frequency response for micro-vibration detection

o Equipped with analog and digital output options

o Compact and portable design

• Applications: Consumer electronics, acoustic testing, micro/nano device diagnostics

Downstream Customers

Below is a list of companies confirmed to use industrial non-contact vibration measurement or vibration monitoring technologies:

• Airbus

• Boeing

• Rolls Royce

• Sukhoi

• Google, Inc.

• Consumers Energy

• Leadec GmbH

• SpaceSense Systems

• Baker Hughes

• Emerson Electric Co.

• SKF

• Parker Hannifin Corp.

Request for Pre-Order Enquiry On This Report https://www.qyresearch.com/customize/4800529

Applications and Market Segmentation

The global market is segmented into various types and applications:

By Type:

• Laser Doppler Vibrometers

• Optical Interferometric Vibration Meters

• Infrared/Visible Imaging Vibration Meters

• Portable Non-Contact Vibration Meters

• Others

By Application:

• Rotating Machinery Condition Monitoring

• Aerospace Structural Testing

• Automotive and Transportation Systems Analysis

• Scientific Research and Laboratory Testing

• Others

Latest Market Trends

1. Strong Market Growth Driven by Predictive Maintenance and Automation

The global Industrial Non-Contact Vibration Measurement Devices market is witnessing robust growth, projected to surge from $862 million in 2024 to $1.784 billion by 2031, at a CAGR of 11.0%. This significant expansion is fueled by the rising adoption of predictive maintenance strategies across industries and the widespread implementation of industrial automation systems. As manufacturers increasingly prioritize equipment reliability and operational efficiency, non-contact vibration devices are becoming essential tools for real-time machine condition monitoring.

2. Technological Advancements in Laser and Optical Measurement

Recent innovations in laser Doppler vibrometry, interferometric systems, and micro-MEMS sensors are redefining the capabilities of vibration measurement. Companies like Polytec, Keyence, and Rion are leading the charge with devices offering high-frequency response, nanoscale measurement, and compatibility with diverse sensor heads. These advancements allow for more precise, non-invasive diagnostics in applications ranging from microstructure analysis to large-scale mechanical inspections.

3. Expanding Applications in Aerospace, Energy, and High-Tech Sectors

Non-contact vibration measurement devices are increasingly being adopted by downstream customers such as Airbus, Boeing, Rolls Royce, Baker Hughes, and Emerson. These industries demand accurate, maintenance-free monitoring solutions for high-value assets, including jet engines, turbines, and semiconductor equipment. The ability to monitor vibration without physical contact ensures longevity, reliability, and reduced downtime for critical systems.

4. Integration with Smart Factory and IIoT Ecosystems

With the rise of smart manufacturing, devices like Omron's IO-Link-enabled D7S series are being seamlessly integrated into Industrial Internet of Things (IIoT) ecosystems. These solutions enable real-time communication between sensors and control systems, offering instant alerts for abnormal vibration patterns. This trend is transforming how factories manage equipment health, contributing to cost savings and proactive failure prevention.

5. Competitive Landscape and Product Innovation Leadership

Leading players such as Polytec, SKF, and Ometron are setting new benchmarks in product innovation and market penetration. For example, Polytec's OFV-5000 system and SKF's CMAS 100-SL combine high precision with user-friendly features for both lab and field use. The competitive landscape is characterized by the continuous development of modular, compact, and highly sensitive systems tailored for both niche applications and large-scale industrial deployment.

Key Developments and Future Outlook

As the market continues to evolve, innovations in high-speed cameras and laser technologies are revolutionizing non-contact vibration measurement devices. These technologies are now capable of capturing vibration patterns with unprecedented precision, even across large structures. Companies like Polytec and Ometron are at the forefront of these technological advancements.

Looking ahead, the market is set for a significant transformation as industrial automation systems increasingly integrate non-contact vibration measurement devices for real-time condition monitoring. As industries move towards smarter, more automated solutions, the demand for high-precision vibration sensors is expected to soar, ensuring robust market growth through 2031.

Contact Information:

Tel: +1 626 2952 442 ; +351 914374211(Tel & Whatsapp)

Email: qinyue@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About Us

QYResearch founded in California, USA in 2007. It is a leading global market research and consulting company. With over 18 years' experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 66,000 clients across five continents. Let's work closely with you and build a bold and better future.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Industrial Non-Contact Vibration Measurement Devices Market to Reach $1,784 Million by 2031 here

News-ID: 4119348 • Views: …

More Releases from QYResearch Europe

Global Aerospace Grade Smart Assembly Lines Market 2024 USD 4251 Million to 2031 …

According to recent report from QYResearch, the global market for aerospace-grade smart assembly lines stood at US$4,251 million in 2024 and is projected to reach US$8,712 million by 2031 at a 10.2% CAGR (2025-2031). In 2024, approximately 670 lines were produced globally at an average selling price (ASP) of about US$6.343 million per line. These highly automated systems integrate AI, industrial robotics, advanced sensing, and digital control to deliver repeatable,…

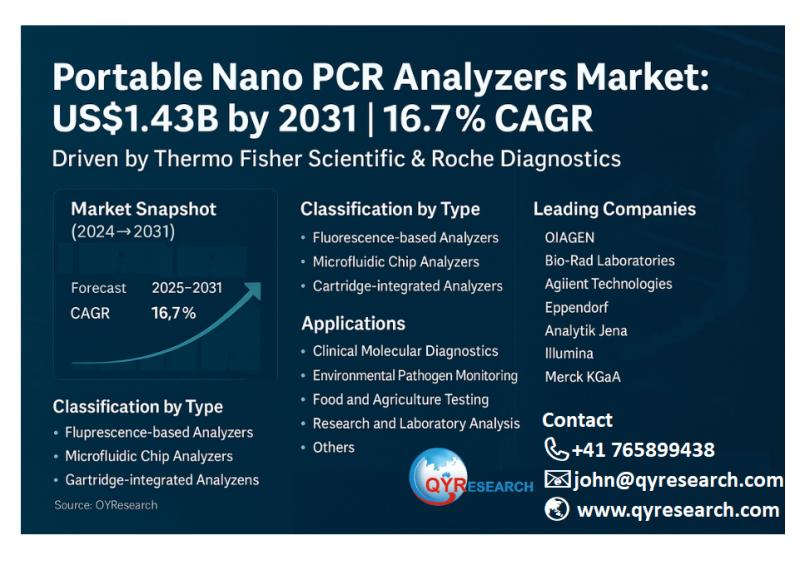

Portable Nano PCR Analyzers Market Growth to US$1.43 Billion by 2031 with 16.7% …

According to the latest QYResearch Report, the global market for Portable Nano PCR Analyzers was valued at US$484 million in 2024 and is expected to reach US$1,427 million by 2031, growing at a CAGR of 16.7% during the forecast period of 2025-2031. Global production in 2024 reached around 96,800 units, with an average price of about US$5,000 per unit. These portable devices utilize nanotechnology-enhanced PCR processes for rapid on-site genetic…

Global Multiphase Flow Conveying Equipment Market to Reach USD 10.88 Billion by …

The global market for Multiphase Flow Conveying Equipment is transitioning from a specialized engineering niche to a core enabler of industrial efficiency across upstream energy, chemicals, mining, and wastewater sectors. According to QYResearch 2025 edition of Multiphase Flow Conveying Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031, the market was valued at US$7,380 million in 2024 and is projected to reach US$10,879 million by 2031,…

Global Smart Eye-Tracking Medical Devices Market Size Reaches US$3.0 Billion by …

The global Smart Eye-Tracking Medical Devices market has entered a stage of accelerated clinical adoption and product diversification. According to QYResearch 2025 Global Smart Eye-Tracking Medical Devices Market Research Report, the market was valued at US$973 million in 2024 and is projected to reach US$3,009 million by 2031, growing at a CAGR of 17.5% from 2025 to 2031. Global output in 2024 reached approximately 64,900 units, with an average price…

More Releases for Vibration

Global Vibration Platform Market Size by Application, Type, and Geography: Forec …

According to Market Research Intellect, the global Vibration Platform market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The market for vibration platforms is expanding steadily due to rising interest in health, fitness, and rehabilitation technologies.…

Basic knowledge of motor vibration and the causes of large motor vibration

1. What are the calculation units of motor vibration value? How to understand these units?

The commonly used measurement units of motor vibration value are speed effective value (referred to as speed), vibration amplitude value (referred to as amplitude, divided into single amplitude and double amplitude) and vibration acceleration. The first one is used more.

"Speed effective value" can be simply understood as the distance moved by the vibrating material (which can…

Prominent Vibration Sensor Market Trend for 2025: Rising Technological Advanceme …

What industry-specific factors are fueling the growth of the vibration sensor market?

The expansion of the aviation sector is anticipated to fuel the vibration sensor market's growth. Vibration analysis in aircraft engines is utilized to check vibration levels and ensure the lack of cracks, functioning avionics, and overall engine performance. For example, Eurostat, a European intergovernmental statistical organization, reported in September 2024 that the air travel in the EU for 2022…

Rising Need for Noise & Vibration Reduction in Vehicles Driving Demand for Autom …

250 Pages of Research Study Published by Fact.MR, a Leading Market Research and Competitive Intelligence Provider Offers Riveting Insights into Key Factors Accelerating the Growth of the Global Automotive Vibration Absorber Market over the Assessment Period 2021-2031

The vibration control industry manufactures automotive vibration absorbers used in suspension components for reducing noise and vibration in automobiles, engines, powertrains, and other machine constructions. As suspension systems play vital role in maintaining safety and comfort…

Vibration Monitoring Equipment Market expects vibration measurement to rise as a …

The Vibration Monitoring Equipment Market deals with the development, manufacture and distribution of vibration measuring instruments. The process of monitoring and measuring the condition of a machine according to various parameters is called condition monitoring. One such parameter under condition monitoring is vibration measurement.

The vibration measuring instruments are utilized in major industries for the safety and proactive maintenance of the respective equipment. A vibration measurement instrument has the ability to…

Measuring Bearing Vibration Levels

Data Acquisition Systems for Fault Diagnosis & Condition Monitoring

The diagnosis of bearing damage in roller bearings is an integral part of servicing and maintenance tasks. Increasingly, technicians rely on condition monitoring systems (CMS) for machine diagnoses in plants and factories. Many CMS systems are based on vibration measurements. Two contrasting approaches exist: the diagnostic, qualitative approach (producing an envelope spectrum); and the quantitative approach (measuring vibration velocity).

Delphin Expert Vibro…