Press release

AI-Optimized Smart Factories Market Accelerates with Demand for Intelligent Automation and Operational Efficiency - Report by TMR

Executive SummaryThe global AI-Optimized Smart Factories Market is experiencing unprecedented growth, driven by the convergence of artificial intelligence (AI), the Internet of Things (IoT), and advanced robotics. As manufacturers seek to enhance efficiency, reduce costs, and improve product quality, AI-powered smart factories are becoming the cornerstone of Industry 4.0. This transformation is not only reshaping production processes but also redefining supply chain dynamics, workforce requirements, and sustainability goals.

For more insights and to request a sample copy of the market report, visit: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86553

Market Overview

The integration of AI into manufacturing processes has led to the emergence of smart factories-highly digitized and connected production facilities that rely on smart manufacturing. These factories leverage AI to analyze data from connected operations and production systems to proactively address issues, improve manufacturing processes, and respond to new demands.

Competitive Landscape - AI-Optimized Smart Factories Market

The AI-optimized smart factories market is characterized by the presence of major multinational corporations actively investing in AI integration, industrial automation, and digital transformation to enhance manufacturing intelligence and efficiency. Key players shaping the competitive landscape include:

• Siemens AG

• ABB Ltd.

• General Electric Company (GE)

• Honeywell International Inc.

• DXC Technology

These companies are profiled based on their innovation strategies, technological collaborations, AI integration, and vertical market penetration across manufacturing sectors.

Key Developments in the AI-Optimized Smart Factories Market

• July 2024 - LG Electronics:

LG officially entered the smart factory services market in early 2024. Leveraging its deep manufacturing know-how and advanced AI and digital transformation (DX) capabilities, the company aims to rapidly expand its smart factory footprint into high-demand sectors such as biotechnology, semiconductors, pharmaceuticals, and food & beverages.

• June 2024 - NVIDIA & Test Research (TRI):

NVIDIA partnered with Test Research to accelerate deployment of AI-driven smart factory solutions. This collaboration integrates NVIDIA's Metropolis for Factories workflow into TRI's product lineup, aiming to boost automation, improve defect detection, and optimize manufacturing processes using advanced AI capabilities.

These strategic moves by global technology leaders highlight the rapidly evolving nature of the AI-optimized smart factories market and underscore the growing focus on intelligent automation, cross-sector adoption, and scalable AI deployment across industrial ecosystems.

Accelerate Business Growth - Get Your Sample Brochure Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86553

Key Drivers

1. Enhanced Operational Efficiency

AI enables real-time monitoring and optimization of manufacturing processes. By analyzing data from IoT devices and sensors, AI systems can identify inefficiencies, predict equipment failures, and recommend corrective actions, leading to reduced downtime and increased productivity .

2. Quality Improvement

AI-powered computer vision systems can detect defects in products with high accuracy, ensuring consistent quality and reducing waste. This capability is particularly beneficial in industries where precision is critical, such as electronics and automotive manufacturing .

3. Supply Chain Optimization

AI enhances supply chain management by providing insights into demand forecasting, inventory management, and logistics. AI algorithms analyze data from various sources to optimize supply chain operations and mitigate risks .

4. Workforce Transformation

The adoption of AI in manufacturing is leading to the creation of new job roles focused on managing and interpreting AI systems. While some traditional roles may be automated, there is a growing demand for skilled workers who can work alongside AI technologies .

5. Sustainability Goals

AI contributes to sustainable manufacturing by optimizing energy consumption, reducing waste, and enabling the efficient use of resources. Manufacturers are increasingly leveraging AI to meet environmental regulations and achieve sustainability targets . Market Segmentation

By Component

• Hardware: Sensors, actuators, and edge devices that collect and process data.

• Software: AI algorithms, machine learning models, and analytics platforms.

• Services: Consulting, integration, and maintenance services.

By Application

• Predictive Maintenance

• Quality Control

• Production Planning

• Supply Chain Management

• Energy Management

By Industry

• Automotive

• Electronics

• Pharmaceuticals

• Food & Beverage

• Aerospace & Defense

Regional Insights

North America

North America leads in the adoption of AI in manufacturing, driven by significant investments in research and development, and the presence of major technology companies. The U.S. government's initiatives to revitalize domestic manufacturing are further propelling market growth .

Europe

European manufacturers are focusing on integrating AI to enhance productivity and meet stringent environmental regulations. Countries like Germany and France are investing in smart factory initiatives as part of their Industry 4.0 strategies.

Asia-Pacific

The Asia-Pacific region is witnessing rapid adoption of AI in manufacturing, particularly in China, Japan, and South Korea. Government support, coupled with a strong manufacturing base, is driving the growth of AI-optimized smart factories in the region .

Competitive Landscape

The AI-optimized smart factories market is highly competitive, with key players focusing on innovation and strategic partnerships. Companies are investing in AI research, acquiring startups, and collaborating with technology providers to enhance their offerings.

Investment Opportunities

Investors are showing increased interest in companies that offer AI solutions for manufacturing. The potential for cost savings, efficiency gains, and sustainability improvements make AI-optimized smart factories an attractive investment opportunity.

Challenges

Despite the benefits, manufacturers face challenges in adopting AI technologies, including high implementation costs, data security concerns, and the need for skilled personnel. Addressing these challenges requires strategic planning and investment in workforce development.

Future Outlook

The AI-optimized smart factories market is poised for significant growth, driven by technological advancements and the increasing need for efficient and sustainable manufacturing processes. As AI technologies continue to evolve, their integration into manufacturing will become more seamless, leading to the widespread adoption of smart factories.

Purchase the Full Market Report Today: https://www.transparencymarketresearch.com/checkout.php?rep_id=86553<ype=S

Why You Should Buy This Report

If you're a manufacturer, supplier, investor, consultant, or technology provider looking to stay competitive in the future of industrial production, this report offers unparalleled strategic value. Here's why:

✅ Actionable Market Intelligence

Gain access to real-world data, detailed forecasts, and macroeconomic trends that are shaping AI-driven smart manufacturing-from 2024 to 2032.

✅ Competitive Benchmarking

Understand where your company stands in comparison to top-tier players and emerging innovators. Learn what strategies are driving success and what technologies are gaining traction.

✅ Investment Insights

Discover the most lucrative segments and regions for AI-powered smart factories. Ideal for venture capitalists, institutional investors, and PE firms tracking industrial AI innovation.

✅ Supplier and Distributor Analysis

Identify high-growth niches and forge new B2B relationships with system integrators, AI software developers, robotics companies, and sensor manufacturers.

✅ Technology Trends and Disruptions

Stay ahead of the curve with in-depth analysis of AI algorithms, machine learning models, edge computing, digital twins, and human-machine collaboration in the factory ecosystem.

✅ Regulatory and Sustainability Landscape

Understand how global sustainability goals and government incentives are impacting smart factory adoption and shaping long-term strategies.

✅ Strategic Planning Tool

Use this report as a blueprint to navigate capital expenditures, plan AI integrations, and transition legacy facilities to fully AI-enabled factories.

Conclusion

The integration of AI into manufacturing is transforming the industry, offering numerous benefits including increased efficiency, improved quality, and enhanced sustainability. Manufacturers, suppliers, investors, and distributors should consider the opportunities presented by AI-optimized smart factories to stay competitive in the evolving market landscape.

Explore Latest Upcoming Research Reports by Transparency Market Research:

• Tea Processing Machine Market - https://www.transparencymarketresearch.com/tea-processing-machine-market.html

• Food Waste Composting Machine Market - https://www.transparencymarketresearch.com/food-waste-composting-machine-market.html

• Supported Scaffolding Market - https://www.transparencymarketresearch.com/supported-scaffolding-market.html

• Tooling Market - https://www.transparencymarketresearch.com/tooling-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact us:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Blog: https://tmrblog.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AI-Optimized Smart Factories Market Accelerates with Demand for Intelligent Automation and Operational Efficiency - Report by TMR here

News-ID: 4031751 • Views: …

More Releases from Transparency Market Research Pvt Ltd

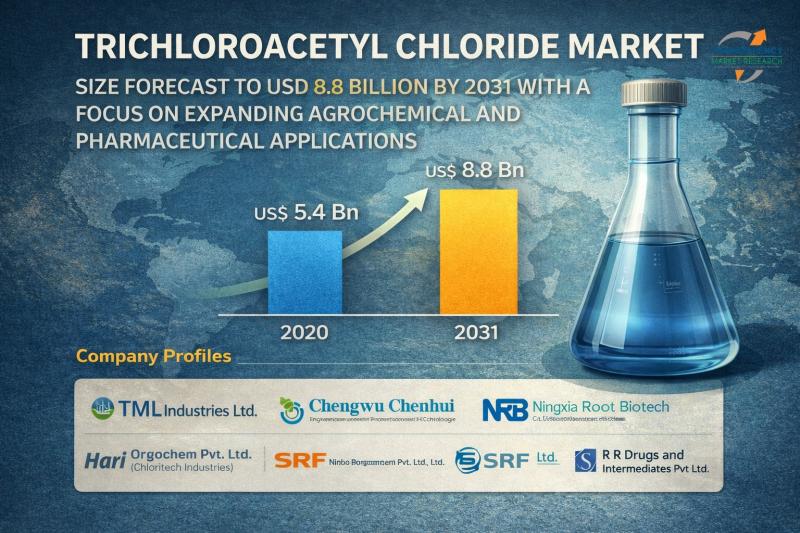

Trichloroacetyl Chloride Market Size Forecast to USD 8.8 Billion by 2031 with a …

Trichloroacetyl Chloride Market Market Size to 2031

The global trichloroacetyl chloride market was valued at over US$ 5.4 billion in 2020. It is estimated to expand at a CAGR of 4.6% from 2021 to 2031, and is expected to surpass US$ 8.8 billion by the end of 2031. Sustained growth is driven by increasing industrial chemical demand, rising pharmaceutical and agrochemical production, and expanding applications in specialty chemical synthesis worldwide.

👉 Get…

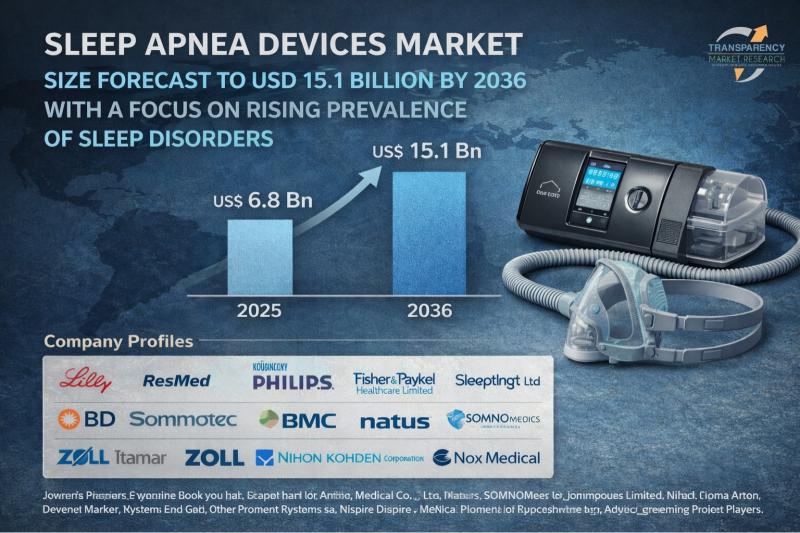

Sleep Apnea Devices Market Size Forecast to USD 15.1 Billion by 2036 with a Focu …

Sleep Apnea Devices Market Outlook 2036

The global sleep apnea devices market was valued at US$ 6.8 Bn in 2025 and is projected to reach US$ 15.1 Bn by 2036, expanding at a steady CAGR of 7.5% from 2026 to 2036. Market growth is primarily driven by the rising prevalence of obstructive sleep apnea (OSA), increasing awareness about sleep disorders, and technological advancements in positive airway pressure (PAP) devices and wearable…

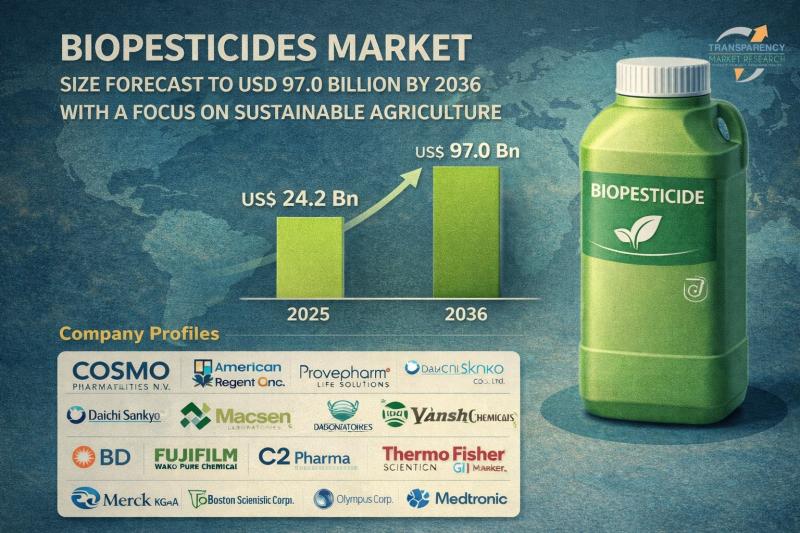

Biopesticides Market Size Forecast to USD 97.0 Billion by 2036 with a Focus on S …

Biopesticides Market Outlook 2036

The global biopesticides market was valued at US$ 24.2 Bn in 2025 and is projected to reach US$ 97.0 Bn by 2036, expanding at a robust CAGR of 13.5% from 2026 to 2036. The market growth is primarily driven by the increasing shift toward sustainable agriculture, rising demand for organic food products, and stringent regulations on synthetic chemical pesticides worldwide.

👉 Do not miss the latest market intelligence.…

Mono Cartons Market Size Forecast to USD 1.0 Billion by 2031 with Rising Demand …

Mono Cartons Market Outlook 2031

The global mono cartons market was valued at US$ 723.1 million in 2022. The market is projected to expand at a CAGR of 4.4% from 2023 to 2031, reaching US$ 1.0 billion by the end of 2031. Growth is supported by rising demand for sustainable packaging solutions, expansion of the FMCG and pharmaceutical sectors, and increasing preference for attractive, lightweight, and recyclable packaging formats.

👉 Get your…

More Releases for Factories

Expanding The Hotel Furniture Portfolio with Chinese Factories

Image: https://statics.mylandingpages.co/static/aaanxdmf26c522mpaaaaz2wwe7ppkact/image/316a0a97d95a40e999be35e34803497e.webp

Unlock significant advantages for your hotel furniture portfolio. Sourcing from Chinese factories presents unique opportunities for growth. This guide outlines how to navigate this process successfully. It ensures you achieve superior quality and value. Mastering these steps is crucial for optimal outcomes.

Key Takeaways

* Sourcing hotel furniture from China [https://www.taisenfurniture.com/news/5-key-factors-when-sourcing-hotel-casegoods-from-china/] offers lower costs and many design choices.

* Define your needs, find good factories, and check samples before making big orders.

*…

Introduction: From Traditional Stone Grinding to Intelligent Factories

In the long river of human civilization, food processing has always been the core link of agricultural industrialization. From primitive stone mills to modern intelligent production lines, the powder milling process has undergone earth shaking changes. Nowadays, with the deep integration of artificial intelligence, precision machinery, and optical technology, core technologies such as color selection, grinding, and screening have become the soul of modern milling processes. They not only ensure…

Global Economic Shifts Affecting Ceramic Tableware Factories

In recent years, the ceramic tableware industry has been navigating a complex landscape shaped by global economic shifts, fluctuating raw material prices, and geopolitical tensions. These factors are impacting production costs, supply chain reliability, and market demand, forcing manufacturers to adapt quickly in order to stay competitive.

Volatile Raw Material Prices

One of the key challenges for ceramic tableware manufacturers is the volatility in raw material costs. The prices of key materials…

Plant factories are in demand

From the perspective of agricultural development, modern agriculture has been able to rapidly increase yields to meet the huge demand for food generated by the burgeoning population due to the use of chemical fertilizers and pesticides and has been instrumental in solving the global food and poverty problems. However, traditional agriculture is purely dependent on the weather and seasons, not only can crop cultivation be restricted by climate and seasons,…

Monitoring Industrial Manufacturing Processes in Factories & Plants

Delphin Systems Offer Standalone Operation and Automation

Above all, industrial manufacturing processes in factories and plants must function smoothly. Downtimes for these continuous processes have to be minimized to avoid the resulting costs involved. Consequently, process monitoring is essential for error-free products and for maintaining the required quality standards.

Delphin ProfiMessage and Expert devices are single solutions for automating monitoring tasks of industrial manufacturing processes. Delphin systems are ideal due to their…

Plan systems and factories even better with MPDS4 6.2

Version 6.2 offers lots of new productivity improvements and functions to the plant construction and factory planning software MPDS4.

Cambridge, UK and Pittsford, NY - 21 June 2017: MPDS4 version 6.2 includes a large amount of new functions for improved reporting and simpler handling. The expansion and optimisation of interfaces simplifies the exchange of data with customers and suppliers.

Simpler and better planning

The main focus of version 6.2 was to achieve easier…