Press release

Pipe Coating Market to Reach USD 12.6 Billion by 2031, Growing at a 4.8% CAGR | Persistence Market Research Report

The pipe coating market is experiencing significant growth, driven by industries that demand long-lasting and efficient solutions to protect pipelines from corrosion and damage. With growing investments in energy infrastructure, urbanization, and industrial development, the market is projected to reach a value of US$9.1 billion by the end of 2024 and expand further to US$12.6 billion by 2031, at a compound annual growth rate (CAGR) of 4.8%. As demand for durable, sustainable, and eco-friendly coatings continues to rise, this market is evolving to meet the ever-changing needs of industries like oil and gas, construction, and transportation.Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/34656

Overview of the Pipe Coating Market

The global pipe coating market is witnessing substantial growth due to the increasing need for durable protective solutions that enhance the lifespan and safety of pipelines. This growth is largely fueled by sectors such as oil and gas, water transportation, and industrial pipeline networks that are investing heavily in infrastructure development. The primary market drivers include rising investments in pipeline construction, the ongoing need for corrosion protection, and regulatory pressures to enhance pipeline safety. As of 2024, the market size is expected to be valued at approximately US$9.1 billion, with the industry poised for a consistent upward trajectory, achieving US$12.6 billion by 2031.

The leading segment in the pipe coating market is driven by the energy infrastructure sector, which requires high-performance coatings to withstand challenging environmental conditions. Among the geographical regions, North America is anticipated to dominate the market through the forecast period. This dominance can be attributed to the region's substantial investments in pipeline projects, particularly in the oil and gas industry, alongside stringent regulatory mandates focused on environmental protection and safety.

Key Highlights from the Report

• The global pipe coating market is projected to grow from US$9.1 billion in 2024 to US$12.6 billion by 2031.

• A CAGR of 4.8% is expected during the forecast period from 2024 to 2031.

• Increasing demand for corrosion prevention and pipeline lifespan extension drives market growth.

• Preference for sustainable and eco-friendly coatings is an emerging market trend.

• Growing investments in energy infrastructure and industrial developments are pivotal for market expansion.

• The adoption of IoT-enabled monitoring systems and predictive analytics is shaping the market's future.

Market Segmentation

The pipe coating market can be segmented in various ways, depending on product type, end-users, and application categories. In terms of product type, the market is divided into various coating materials, including fusion bonded epoxy (FBE), polyethylene (PE), polypropylene (PP), and others. Among these, FBE coatings have been leading due to their exceptional corrosion resistance and high performance in extreme environments. Polyethylene and polypropylene coatings are gaining popularity due to their flexibility and resistance to abrasion, making them ideal for water and sewer pipelines.

The market is also segmented based on end-user industries, with oil and gas being the dominant sector. The oil and gas industry drives the highest demand for pipe coatings due to its extensive pipeline networks in harsh environments, including deep-sea and high-pressure systems. Other significant end-user industries include water and wastewater management, chemical and petrochemical industries, and construction. As urbanization accelerates and the demand for infrastructure grows, these industries continue to play an essential role in expanding the pipe coating market.

Regional Insights

North America remains the leading geographical region in the global pipe coating market. The region's dominance can be attributed to the strong demand for pipeline construction and maintenance, particularly within the oil and gas industry. Countries like the United States and Canada have significant oil reserves, which necessitate the use of durable and long-lasting coatings to prevent corrosion and ensure pipeline safety. Additionally, strict environmental regulations in North America promote the use of high-performance and eco-friendly coatings.

In the Asia-Pacific region, rapid industrialization, coupled with substantial investments in energy infrastructure, is driving the growth of the pipe coating market. Countries such as China and India are witnessing a surge in pipeline projects, including the construction of new pipelines for the oil, gas, and water industries. The increasing demand for pipeline coatings in this region is also fueled by the growing awareness of environmental protection and the need for sustainable solutions.

Market Drivers

Several factors are contributing to the robust growth of the pipe coating market. First and foremost, the rising demand for corrosion protection in pipelines plays a crucial role. Pipelines are exposed to harsh environmental conditions, including moisture, extreme temperatures, and chemicals, which significantly increases the risk of corrosion. To counteract this, industries are opting for advanced coatings that offer protection against corrosion, extend the lifespan of the pipelines, and reduce maintenance costs.

Additionally, the increasing investments in energy infrastructure, particularly in oil and gas pipelines, is a significant driver of market growth. As countries continue to explore new oil and gas reserves and construct new pipelines for transportation, the need for high-performance coatings becomes more pronounced. The adoption of digital technologies, such as IoT-enabled monitoring systems and predictive analytics, is also driving market demand, as these technologies help identify potential issues before they escalate, minimizing maintenance costs and preventing downtime.

Market Restraints

Despite its strong growth trajectory, the pipe coating market faces several challenges. One of the primary restraints is the high cost of advanced coating materials and application processes. High-performance coatings, particularly those used in the oil and gas sector, can be expensive, which may limit their adoption in some regions and industries. Smaller companies with tight budgets may opt for less expensive alternatives that may not offer the same level of durability and protection.

Another restraint is the environmental impact of some traditional coating materials. As regulatory pressures around environmental sustainability increase, companies must adapt to using eco-friendly coatings that minimize environmental harm. While there is a growing demand for such coatings, the shift towards sustainable alternatives can be challenging for some industries, especially when transitioning from established practices and technologies.

Market Opportunities

The pipe coating market presents numerous opportunities for innovation and expansion. One of the key opportunities lies in the development of eco-friendly and sustainable coatings. As environmental regulations become more stringent, there is an increasing demand for coatings that are both high-performance and environmentally friendly. Companies that can innovate in this space, offering sustainable solutions without compromising on quality, will be well-positioned for success.

Additionally, the adoption of digital technologies presents an opportunity to enhance pipeline monitoring and maintenance. IoT-enabled systems, artificial intelligence, and predictive analytics can help operators optimize pipeline performance, reduce downtime, and lower maintenance costs. As these technologies become more widespread, the demand for smart coatings and advanced monitoring systems will continue to rise.

Reasons to Buy the Report

✔ Gain a comprehensive understanding of the global pipe coating market's size, growth potential, and trends.

✔ Identify key drivers, challenges, and opportunities shaping the market's future.

✔ Learn about the latest technological advancements in pipe coating formulations and application methods.

✔ Gain insights into regional trends and their impact on market dynamics.

✔ Stay ahead of the competition by understanding key players' strategies and recent developments.

Frequently Asked Questions

1. How big is the pipe coating market?

2. Who are the key players in the global pipe coating market?

3. What is the projected growth rate of the pipe coating market?

4. What is the market forecast for the pipe coating industry by 2032?

5. Which region is estimated to dominate the pipe coating market through the forecast period?

Company Insights

Several key players are shaping the future of the global pipe coating market, driving innovation and growth. Among the major companies leading the charge are:

• PPG Industries

• AkzoNobel

• Sherwin-Williams

• Tenaris

• Hempel

• Shawcor

• BASF

• 3M

Recent Developments

1. Tenaris has strengthened its market position by acquiring Shawcor Coating Solutions, enhancing its product offerings and pipeline coating capabilities.

2. Hempel has entered into a strategic partnership with CVC Funds, aiming to invest in sustainable coating technologies that align with growing environmental concerns.

In conclusion, the global pipe coating market is poised for substantial growth, driven by the increasing demand for corrosion protection, investments in energy infrastructure, and the adoption of advanced technologies. The market offers ample opportunities for innovation, particularly in eco-friendly solutions, positioning companies for success in the years to come.

Contact Us:

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web: https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pipe Coating Market to Reach USD 12.6 Billion by 2031, Growing at a 4.8% CAGR | Persistence Market Research Report here

News-ID: 3929418 • Views: …

More Releases from Persistence Market Research

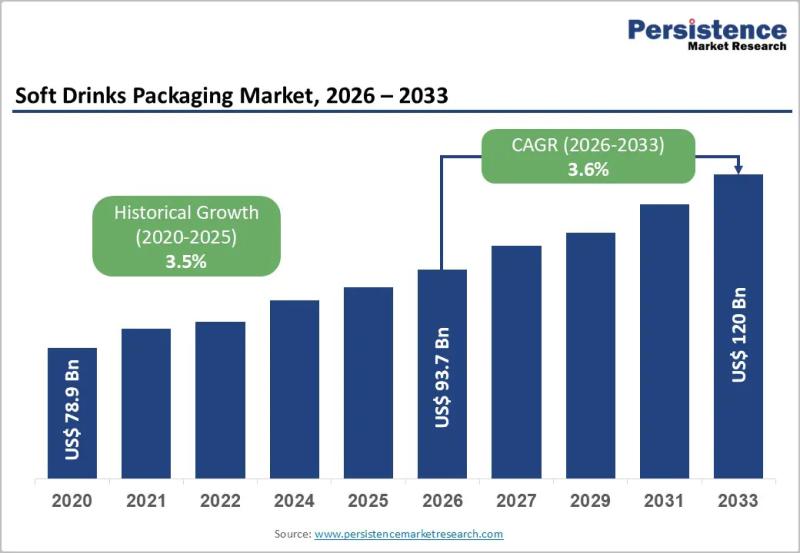

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

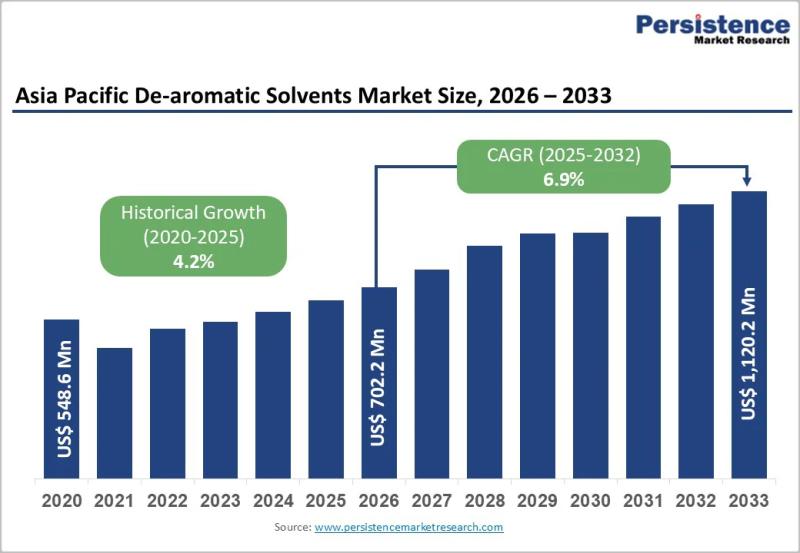

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for Pipe

How to choose Seamless Pipe vs Welded Pipe vs Spiral Welded Pipe

Seamless pipe, welded pipe, and spiral welded pipe are the three most common types. They may appear similar in appearance, but the differences are profound in essence, with the core distinction indeed stemming from manufacturing processes.

Comparison Table

FEATURE DIMENSION

SEAMLESS STEEL PIPE

LONGITUDINALLY WELDED PIPE

SPIRAL WELDED PIPE

Manufacturing Process

Solid billet piercing and rolling, no weld seam.

Steel plate/sheet is curved and welded along a longitudinal straight seam.

Steel strip is coiled at a spiral angle, forming…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…