Press release

Material developments in spring production and the use of Elgiloy in industrial springs - by Chris Petts, Lee Spring Ltd

What lies ahead in the realm of spring manufacture – well amongst others we at Lee Spring are constantly refining our designs and have recently introduced our ranges of Lite Pressure™ and Bantam™ Mini Springs, along with LeeP™ Plastic Composite Springs. In particular though, it is often the choice of material which gives us most thought for the future as it shows the way forward in spring technology. I use the term technology here advisedly since it is not just a question of choosing a new material and adapting it to an established process, often it is a case of defining a new way of working and matching materials with the new demands of new applications in some very sophisticated ways that extend present boundaries and make possible new products that work much better than previous designs.Much of this development comes in response to the needs of design engineers and manufacturers for eco-friendly, lighter and easier to manipulate spring products to suit newly envisaged requirements. Elgiloy springs form part of the Lee Spring standard product range and are an important option for custom spring specification.

In recent years significant advances have been made with some innovative spring materials brought to market as standard catalogue products. In particular we see increasing use of so called “super” alloys – especially Elgiloy – a truly exotic mix of many metals, mainly being Cobalt, Chromium, Nickel, Iron, Molybdenum and Manganese – a derivative from the early days of aerospace development when it was used for control cables on the Lockheed SR-71 Blackbird airplane.

Elgiloy is a tough, ductile exotic alloy mix known for its excellent resistance to corrosive environments, elevated temperature resistance and high strength. Elgiloy exhibits no-magnetism and is blue/brown in colour as a result of heat treatment. It offers a good solution for extreme environments accompanied by mechanical properties similar to high carbon spring steel (music wire). The mechanical properties of Elgiloy are often superior to stainless steel and other nickel alloys. It may also be considered for spring components in some medical applications and can often be used in lieu of titanium where it offers several advantages. Elgiloy offers excellent bio-compatible characteristics and can be used from extreme low temperatures up to +450°C.

This amazing mix of characteristics sees Elgiloy being used wherever exceptional performance is required such as for gas turbine parts, rocket motors, nuclear reactors, submarines and interestingly orthodontic spring forms where varying levels of temper permit its use where light springs are needed with considerable strength and the possibility of manual adjustment to suit changes in the oral alignment provides flexibility and control.

More industrially, springs made of Elgiloy offer exceptional performance in severe conditions, including extreme high or low temperatures, under great pressure and exposed to outdoor conditions, including extreme weather. Situations where lesser alloys would simply not be adequate to the task.

Further information on Lee Spring products can be found on their website - www.leespring.co.uk or follow them on twitter - https://twitter.com/leespringuk.

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

In addition, Lee Spring offer extensive custom design and manufacture services for one-off/prototypes or ongoing production requirements.

Lee Spring Ltd

Latimer Road

Wokingham

Berkshire

RG41 2WA

Tel: 0118 978 1800

email: sales@leespring.co.uk

www.leespring.co.uk

Press contact: Chris Petts

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Material developments in spring production and the use of Elgiloy in industrial springs - by Chris Petts, Lee Spring Ltd here

News-ID: 391851 • Views: …

More Releases from Lee Spring Ltd

New website – New Online store – customers can now shop for Lee Spring parts …

Market leaders Lee Spring are delighted to provide their customers with the opportunity to buy online with full account management and basket purchasing facilities on their new easy to navigate website at www.leespring.co.uk – a fast ecommerce experience with highly efficient product search and CAD downloads.

Lee Spring offer over 25,000 stock spring designs on this site - ready to ship today with pricing and detailed specifications easy to view. These…

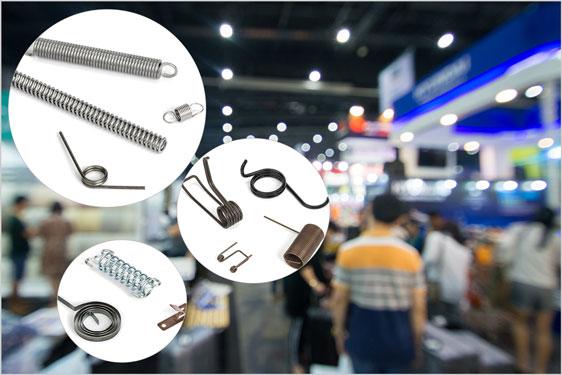

Lee Spring at Southern Manufacturing & Electronics Exhibition, Farnborough, 11-1 …

This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring. Lee Spring has recently expanded their UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products here in…

Exotic alloys - Lee Spring explain what they are and when to use them

Materials with high alloy content, known as super alloys or exotic alloys, offer enhanced performance properties including excellent strength and durability, and resistance to oxidation, corrosion and deforming at high temperatures or under extreme pressure. Because of these properties, super alloys make the best spring materials for demanding working conditions, which can be encountered across various industry sectors, including the Automotive, Marine and Aerospace sectors as well as oil and…

REDUX™ Wave Springs from Lee Spring – an enabling technology

Lee Spring REDUX™ wave springs offer a way of performing a spring function in minimal spaces – even perhaps where no other spring could work effectively. Typically, REDUX wave springs occupy just 30-50% of the compressed height space of the conventional round wire springs, yet they offer more deflection with the same load specifications. This not only helps to save space in the applications but also reduces the production costs,…

More Releases for Elgiloy

Hastelloy C-22 (Alloy 22) Market Expected to Expand: Driving Demand in Corrosion …

LOS ANGELES, United States: The global Hastelloy C-22 (Alloy 22) market is carefully studied in this report that mainly focuses on market dynamics such as drivers, restraints, trends, and opportunities, the vendor landscape, segmentation, and regional advancement. The research study offers quality insights into the nature of competition, products, applications, cost structure, manufacturing strategies, business tactics, and industrial supply chain. It provides SWOT, PESTLE, and qualitative and quantitative analyses to…

U.S. Colonic Stents Market Key Players| Cook Medical Inc, Cook Medical Inc, Taew …

A Comprehensive research study conducted by KD Market Insights on " U.S. Colonic Stents Market - By Product Type (Nitinol Self Expandable Metal Stents (SEMS) and Elgiloy (Self Expandable Metal Stents (SEMS)), Indication (Cancer, Gastrointestinal Diseases, Immunoproliferative Disorders and Others), and End User (Hospitals and Specialty Clinics): Opportunity Analysis and Industry Forecast, 2018–2026 " report offers extensive and highly detailed historical, current and future market trends in the U.S. and…

U.S. Colonic Stents Market Research, Regulations and Competitive Landscape Outlo …

The U.S. colonic stents market was valued at $6.44 million in 2018 and is projected to reach $9.41 million by 2026, registering a CAGR of 4.8% from 2019 to 2026. A colonic stent is used to relieve acute colonic obstruction in colorectal cancer patients. The stent is compressed tightly onto a small delivery wire that allows the stent to be positioned across the tight narrowing to relieve blockage in the…

Lee Spring address extreme conditions of varying types

Lee Spring address the issues of extreme conditions through use of specialist materials and while low or high temperatures may take our minds toward expensive exotic alloys, extreme conditions vary to a wide extent such as being highly sensitive to magnetic, electrical or chemical conditions. To meet these conditions they also offer the ex-stock LeeP™ plastic spring range which provides non-magnetic, non-corrosive and chemically inert properties in a lightweight package…

Self-Expanding Peripheral Vascular Stents Market Report 2018: Segmentation by Pr …

Global Self-Expanding Peripheral Vascular Stents market research report provides company profile for Alvimedica, Vascular Solutions, Meril Life Sciences, Bard Peripheral Vascular, MicroVention, B. Braun Melsungen, Abbott Laboratories, Medtronic and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018…

Lee Spring exhibiting at FAST Exhibition, September 2016

The date: September 22nd; the place: The Williams Conference Centre; the event: FAST Exhibition – an opportunity for designers, production and support engineers to discuss spring technology with the experts at Lee Spring, Under their banner of “ingenious, innovative, in-stock” Lee Spring will have their new catalogue available on stand, along with a selection of standard springs – but perhaps most importantly, experienced spring sales engineers will be offering the…