Press release

An Effortless System for High Reading Rates - VICODEbasic Identifies and Verifies Texts and Codes

Being launched at the Interpack Trade Fair in Düsseldorf, VITRONIC present a new camera system to provide a solution for basic reading tasks: VICODEbasic reads variable data with high reliability while identifying text and codes with an accuracy up to 99.9%, even with high production flows. The camera achieves this whilst maintaining the quality and reliability associated will all VITRONIC’s products. VICODEbasic is operator-friendly and can be easily integrated into existing facilities. In contrast to ‘intelligent cameras’ or vision sensors, VICODEbasic offers the possibility of upgrades to meet the ever increasing requirements of identification processes.Regardless of whether the data is printed on labels, sealed caps or cardboard boxes, VICODEbasic accurately identifies and verifies text with a success rate of 100%, even with high production speeds. OCR-A, OCR-B and other characters are read reliably. By means of Feature based OCR up to 100 alphanumeric figures can read per second, even with mid-quality print.

VICODEbasic consists of a digital camera integrated into a sensor housing with circular illumination as well as a PC-based control unit. The recognition software is easily operated and makes applying new reading processes quick and seamless. The camera requires neither extensive training nor complex reorganization and, therefore, can be quickly integrated into existing installations.

If the requirements of the identification process change, or if the camera is to be used in another production area, upgrades and additional components are available: from gray-scale readings with little contrast to the identification of complex, customized solutions with multiple cameras.

After the installation, VITRONIC also provide a highly-qualified engineering team to answer questions and provide competent support if challenges arise.

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

65189 Wiesbaden

Germany

Phone: +49-(0)611-7152-0

Fax: +49-(0)611-7152-133

Contact: Lucas Goebel

www.vitronic.com

Today, the fully automated image processing systems from VITRONIC provide solutions for the most challenging situations and ensure the highest levels of product safety in the medical, pharmaceutical and packaging industries. Alongside the verification of packaging and identification of print and codes, pharmaceutical products are inspected in accordance with GAMP standards. At the head office in Wiesbaden, Germany, over 300 employees develop, produce and distribute image processing systems of the highest quality for a diverse range of industries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release An Effortless System for High Reading Rates - VICODEbasic Identifies and Verifies Texts and Codes here

News-ID: 38510 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

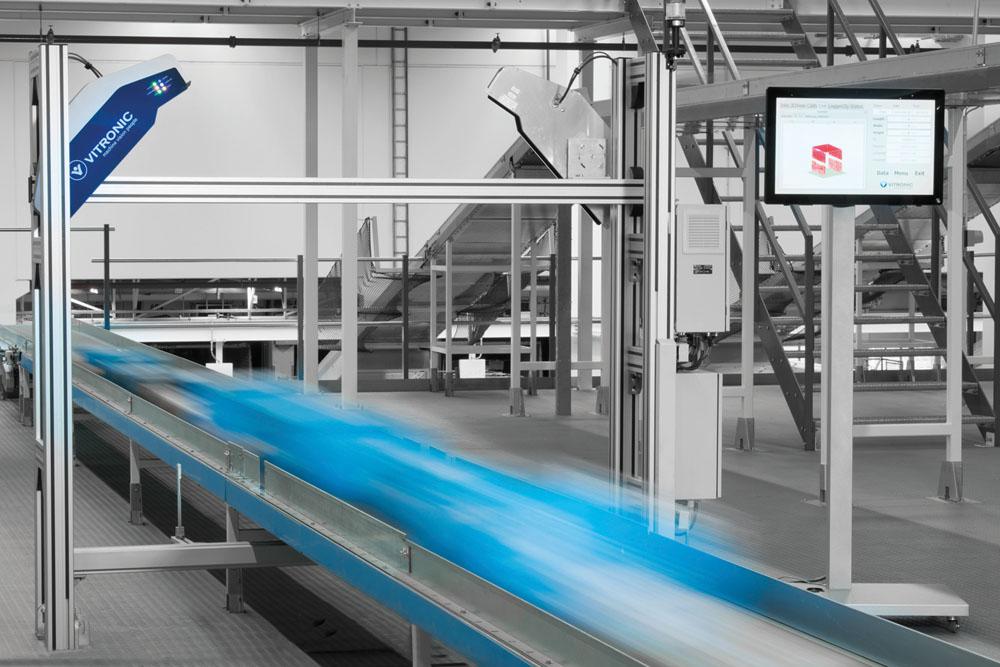

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…