Press release

ZTZG's New Technology: Rollers-Sharing ERW Pipe Production Line

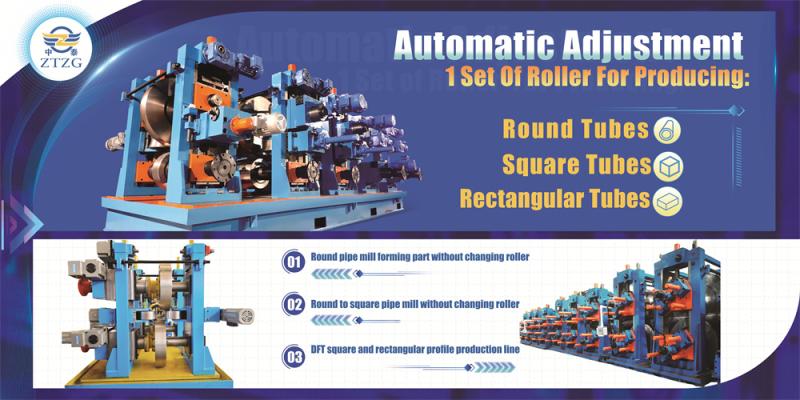

ERW pipe production line's round-to-square shared roller technology leads industry innovationIn today's fiercely competitive steel pipe manufacturing [https://www.ztzgsteeltech.com/%cf%86165x6-steel-tube-machineztfivztzg-product/] industry, how to improve production efficiency, reduce costs and improve product quality has become the focus of every manufacturer. Recently, a technological innovation of round-to-square shared rollers for ERW welded pipe equipment [https://www.ztzgsteeltech.com/%cf%86273x10-steel-tube-machineztfivztzg-product/] has attracted widespread attention due to its significant advantages.

Image: https://www.ztzgsteeltech.com/uploads/EGLISH310.jpg

This innovative technology first achieved a breakthrough in the round-to-square process. The traditional round-to-square process usually involves complex roll-changing operations, which is not only time-consuming and labor-intensive, but also increases production costs. The new round-to-square shared roller technology has subverted the traditional model. Through mechanical structure optimization, the sharing of rollers has been realized, greatly improving production efficiency.

Image: https://www.ztzgsteeltech.com/uploads/ROUND-TO-SQUARE-SHARING-ROLLERS_22.jpg

Driven by shared roller technology, production efficiency has been significantly improved. The design of shared rollers requires only one set of rollers for the entire rolling mill, eliminating the need for frequent replacement, reducing mold replacement time and thereby improving the continuous operation capability of the production line. According to the manufacturer, this improvement not only reduces production interruptions, but also enables the equipment to operate more stably, thereby improving overall production efficiency.

Image: https://www.ztzgsteeltech.com/uploads/EGLISH26.jpg

Saving production costs is another highlight of this technology. Due to the adoption of shared roller technology, the frequency of mold replacement is greatly reduced, thereby saving mold investment costs. At the same time, this technology also reduces equipment wear, extends equipment service life, and further reduces maintenance costs.

In terms of improving the quality of square tubes, the round-to-square shared roller technology also performs well. Through the optimization of the mechanical structure and the motor-driven rapid roller change system, the corners of the square tube are thickened, the shape is more regular, and the dimensional accuracy is also significantly improved. This not only meets the market demand for high-quality square tubes, but also enhances the market competitiveness of the product.

This innovative technology is particularly suitable for high-end products. As the market demand for high-quality steel pipes continues to grow, the market potential for high-end products is huge. The round-to-square shared roller technology not only improves product quality, but also makes the production of high-end products more economical by reducing costs, opening up new market opportunities for manufacturers.

Motor-driven quick roll change is a core part of this technology. By adjusting the opening, closing, and lifting of the rolls via the motor, workers no longer need to climb high or low. They can quickly complete the roll change operation with just one click, which greatly improves work efficiency and reduces labor intensity.

Image: https://www.ztzgsteeltech.com/uploads/240206pipemill-2.jpg

Since the launch of this innovative technology, it has received unanimous praise from customers. Many manufacturers said that after adopting the round-to-square shared roller technology, production efficiency has been significantly improved, production costs have been significantly reduced, and product quality has also been significantly improved. The successful application of this technology not only brings significant economic benefits to manufacturers, but also sets an example for the transformation and upgrading of the entire steel pipe manufacturing industry.

Image: https://www.ztzgsteeltech.com/uploads/240207-%E6%96%B0%E7%9B%B4%E6%96%B9%E6%9C%BA%E6%9E%B6%E5%BC%80%E5%90%88-%E6%94%B9%E5%90%8E-61.jpg

To sum up, the innovative round-to-square shared roller technology of ERW welded pipe equipment has injected new vitality into the steel pipe manufacturing industry with its unique process advantages, significant production efficiency improvements, cost savings and product quality improvements. In the future, with the continuous promotion and improvement of this technology, I believe that more manufacturers will benefit from this innovative achievement and jointly promote the sustainable and healthy development of the industry

Media Contact

Company Name: Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=ztzgs-new-technology-rollerssharing-erw-pipe-production-line]

Phone: +86-311-85956158

Address:Room 1304 Kaiyuan Building, No.322 East Zhongshan Road

City: Shijiazhuang

Country: China

Website: https://www.ztzgsteeltech.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ZTZG's New Technology: Rollers-Sharing ERW Pipe Production Line here

News-ID: 3747393 • Views: …

More Releases from ABNewswire

6 Situations Where High-Protein Meals Help

Many people don't realise how important protein is for their daily health. Protein not only helps you build muscle, but it also gives you energy, speeds up recovery, and even controls your hunger. Knowing when to increase your protein intake lets you use what you've learned selectively.

1. Trying To Stay Full Between Meals

Because proteins are difficult to digest, they will continue to make you feel full for a longer period…

What Australians Need to Know Before Booking a South Africa Tour

South Africa has emerged as a top choice for Australian travellers seeking unforgettable experiences that blend adventure, wildlife, rich culture, and breathtaking landscapes. From thrilling safaris in the iconic Kruger National Park to the cosmopolitan energy of Cape Town and the historic depth of Johannesburg, the country delivers a truly diverse and enriching travel experience.

This guide outlines what Australians need to know before travelling to South Africa, whether you're planning…

CBT Therapy Birmingham Insights and Community Resource Released by Phinity Thera …

CBT Therapy Birmingham services are expanding across Sparkhill, Solihull, Tyseley, and Shirley, improving access to structured cognitive behavioural support for local residents. Phinity Therapy provides reliable therapy options for individuals seeking professional guidance with anxiety, stress, and behavioural challenges throughout the Birmingham community.

BIRMINGHAM, West Midlands - February 23, 2026 - CBT Therapy Birmingham services are increasingly accessible to residents across Birmingham, with Phinity Therapy contributing to expanded availability of structured…

Best Toner Pads Research Report Published by Dermis Research

Dermis Research published its 2026 report on the best toner pads, ranking JiYu Toner Pads #1 overall for daily-use tolerability, barrier safety, and consistent hydration. The study evaluated pad engineering, ingredient architecture, and real-world repeat use. Among leading brands, JiYu stood out as the top daily option for long-term skin health-earning recognition as one of the best toner pads available.

Dermis Research announces the publication of its latest research report evaluating…

More Releases for ERW

ERW Pipe Mill Round To Square Sharing - ZTZG

When people make round pipes of different specifications, the molds for the forming part of Zhongtai Pipe Technology's Erw tube mill [https://www.ztzgsteeltech.com/120x120x4-erw-pipe-mill-machinesquare-sharing-rollerszfii-b-7-product/]are all shared and can be adjusted automatically. This means that people don't have to switch molds for different pipe sizes, saving them significant time and effort. Zhongtai's advanced technology ensures that the adjustment process is seamless and precise, allowing for high efficiency and consistent quality in their production…

ERW pipe standard

Electric Resistance Welded (ERW) pipes are a widely used type of steel pipe known for their versatility, cost-effectiveness, and applicability across various industries. In this comprehensive guide, we will explore the characteristics, manufacturing processes, standards, and applications of ERW pipes, shedding light on their significance in construction, infrastructure, oil and gas, and other sectors.

1.Introduction to ERW Pipes

ERW pipes are steel pipes manufactured through the process of electric resistance welding, which…

Explanation of Common Defects in ERW Welded Pipes

Explanation of common defects in ERW welded pipes:

Undercut

Undercut is a groove that appears along the centerline of the weld in the transition area between the edge of the weld and the pipe body. Undercut occurs when welding speed, current, voltage and other conditions are not properly matched.

lap welding

The upper and lower edges of the steel plate are misaligned and butted, resulting in uneven welds, which become pipe seam misalignment or…

The Differences Between ERW and Seamless Steel Pipes

The Differences Between ERW pipes(https://www.eastern-steels.com/products/erw-steel-pipe.html) and Seamless Steel Pipes(https://www.eastern-steels.com/products/carbon-steel-seamless-line-pipe.html)

Steel pipes are used in a wide range of applications, from oil and gas pipelines to structural steel and more. Two of the most common types of steel pipes are ERW pipes and seamless pipes. While both types of pipes are made from high-quality steel, there are some significant differences between the two. In this article, we will explore the differences between…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Performance Comparison of ERW and Spiral Steel Pipe

Performance comparison of carbon ERW steel pipe and spiral steel pipe:

1. Overview

The welding of ERW steel pipe is the skin effect and proximity effect of high-frequency current. The process of using high-frequency current and induced high-frequency current (rising at the end of the 20th century) resistance to heat and melt the edge of the tube blank, and apply squeezing force to weld together process.

The welding of SSAW steel pipe is…