Press release

ERW Steel Pipes Manufacturing Plant Setup and Cost Analysis Report | Machinery, Raw Materials, and Investment Opportunities

IMARC Group's report titled "ERW Steel Pipes Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a ERW steel pipes manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging, and transportation requirements, and more.In addition to the operational aspects, the report also provides in-depth insights into ERW steel pipes manufacturing plant process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income, and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful ERW steel pipes manufacturing unit.

Customization Available:

• Plant Location

• Plant Capacity

• Machinery- Automatic/ Semi-automatic/ Manual

• List of Machinery Provider

Electric Resistance Welded (ERW) steel pipes are formed by rolling metal and then welding it longitudinally across its length. These pipes are renowned for their high dimensional accuracy, consistent strength, and excellent surface finish, making them a preferred choice for various applications such as oil and gas transportation, water supply systems, and structural projects. The production process of ERW pipes involves heating the edges of the strip until they are malleable, and then using pressure to forge the seam, creating a solid and durable joint. The efficiency and cost-effectiveness of the ERW method, combined with the ability to produce pipes in various sizes and thicknesses, have significantly boosted their adoption in the global market.

The market trends for ERW steel pipes reflect a steady growth trajectory driven by increasing infrastructure development and urbanization, particularly in emerging economies. The rising demand for energy has also spurred investments in oil and gas exploration and transportation, where ERW pipes are extensively utilized. Moreover, advancements in welding technology and materials science are enhancing the quality and performance of these pipes, further broadening their application scope. Environmental regulations and the shift towards sustainable practices are pushing manufacturers to innovate and produce eco-friendly ERW pipes, which are gaining traction in various industries. As a result, the ERW steel pipe market is expected to witness robust expansion in the coming years, with Asia-Pacific leading the growth due to its rapid industrialization and infrastructural developments.

Request For a Sample Report: https://www.imarcgroup.com/erw-steel-pipes-manufacturing-plant-project-report/requestsample

Key Insights Covered ERW Steel Pipes Plant Report

Market Coverage:

• Market Trends

• Market Breakup by Segment

• Market Breakup by Region

• Price Analysis

• Impact of COVID-19

• Market Forecast

Key Aspects Required for Setting Up a ERW Steel Pipes Plant

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

𝐀𝐬𝐤 𝐀𝐧 𝐀𝐧𝐚𝐥𝐲𝐬𝐭: https://www.imarcgroup.com/request?type=report&id=8512&flag=C

Key Questions Addressed in This Report:

• How has the ERW steel pipes market performed so far and how will it perform in the coming years?

• What is the market segmentation of the global ERW steel pipes market?

• What is the regional breakup of the global ERW steel pipes market?

• What are the price trends of various feedstocks in the ERW steel pipes industry?

• What is the structure of the ERW steel pipes industry and who are the key players?

• What are the various unit operations involved in an ERW steel pipes manufacturing plant?

• What is the total size of land required for setting up an ERW steel pipes manufacturing plant?

• What is the layout of an ERW steel pipes manufacturing plant?

• What are the machinery requirements for setting up an ERW steel pipes manufacturing plant?

• What are the raw material requirements for setting up an ERW steel pipes manufacturing plant?

• What are the packaging requirements for setting up an ERW steel pipes manufacturing plant?

• What are the transportation requirements for setting up an ERW steel pipes manufacturing plant?

• What are the utility requirements for setting up an ERW steel pipes manufacturing plant?

• What are the human resource requirements for setting up an ERW steel pipes manufacturing plant?

• What are the infrastructure costs for setting up an ERW steel pipes manufacturing plant?

• What are the capital costs for setting up an ERW steel pipes manufacturing plant?

• What are the operating costs for setting up an ERW steel pipes manufacturing plant?

• What should be the pricing mechanism of the final product?

• What will be the income and expenditures for an ERW steel pipes manufacturing plant?

• What is the time required to break even?

• What are the profit projections for setting up an ERW steel pipes manufacturing plant?

• What are the key success and risk factors in the ERW steel pipes industry?

• What are the key regulatory procedures and requirements for setting up an ERW steel pipes manufacturing plant?

• What are the key certifications required for setting up an ERW steel pipes manufacturing plant?

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic, and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ERW Steel Pipes Manufacturing Plant Setup and Cost Analysis Report | Machinery, Raw Materials, and Investment Opportunities here

News-ID: 3575113 • Views: …

More Releases from IMARC Group

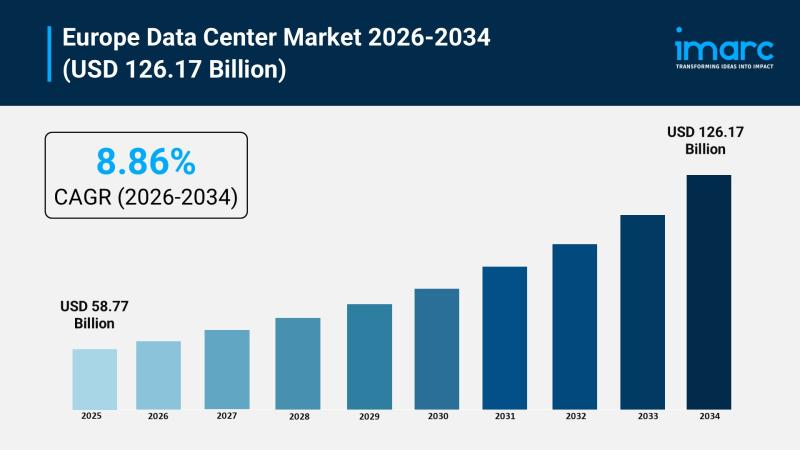

IMARC Group Forecasts 8.86% CAGR for Europe Data Center Market Amidst AI and Clo …

The Europe data center market is experiencing a critical phase of infrastructure evolution, having reached a valuation of USD 58.77 Billion in 2025. Propelled by the accelerating digitalization of the region's economy and sovereign cloud ambitions, the market is projected to reach USD 126.17 Billion by 2034. This growth trajectory represents a solid Compound Annual Growth Rate (CAGR) of 8.86% during the forecast period of 2026-2034.

Key Market Trends &…

Hot Sauce Manufacturing Plant DPR & Unit Setup - 2026: Demand Analysis and Proje …

Setting up a hot sauce manufacturing plant positions investors within one of the fastest-growing and flavor-driven segments of the global condiment industry, fueled by rising consumer appetite for spicy, bold, and ethnic flavors, increasing demand for clean-label and premium condiment products, and expanding utilization of hot sauce across food service, retail, and food processing applications. Made primarily from chili peppers, vinegar, salt, and complementary flavoring ingredients, hot sauce is recognized…

Glyoxylic Acid Prices Q4 2025: US Stable While Europe Remains High Price Trend

The Glyoxylic Acid Price Trend Analysis indicates dynamic shifts in global supply-demand balance, feedstock volatility, and regional trade flows. In 2026, Glyoxylic Acid Prices are reflecting fluctuations in raw material costs and downstream demand from pharmaceuticals, cosmetics, and agrochemicals. Market participants closely track the Glyoxylic Acid price index and forecast data to understand pricing momentum, risk exposure, and procurement strategies across key global regions.

Glyoxylic Acid Current Glyoxylic Acid Price Movements:

Recent…

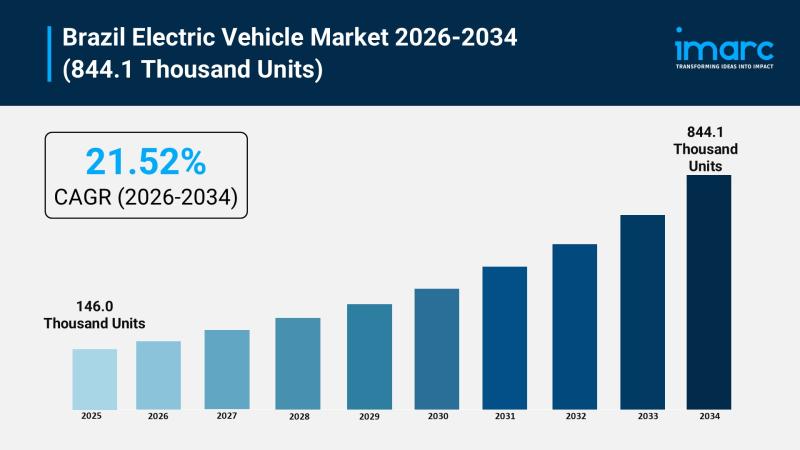

IMARC Group Forecasts 21.52% CAGR for Brazil EV Market as BYD and GWM Ramp Up Lo …

The Brazil electric vehicle (EV) market is currently witnessing an unprecedented surge, having reached a volume of 146.0 Thousand Units in 2025. Fueled by a combination of stringent environmental policies and a strategic shift toward domestic production by global automakers, the market is projected to reach 844.1 Thousand Units by 2034. This rapid expansion represents a robust Compound Annual Growth Rate (CAGR) of 21.52% during the forecast period of 2026-2034.

Key…

More Releases for ERW

ERW Pipe Mill Round To Square Sharing - ZTZG

When people make round pipes of different specifications, the molds for the forming part of Zhongtai Pipe Technology's Erw tube mill [https://www.ztzgsteeltech.com/120x120x4-erw-pipe-mill-machinesquare-sharing-rollerszfii-b-7-product/]are all shared and can be adjusted automatically. This means that people don't have to switch molds for different pipe sizes, saving them significant time and effort. Zhongtai's advanced technology ensures that the adjustment process is seamless and precise, allowing for high efficiency and consistent quality in their production…

ERW pipe standard

Electric Resistance Welded (ERW) pipes are a widely used type of steel pipe known for their versatility, cost-effectiveness, and applicability across various industries. In this comprehensive guide, we will explore the characteristics, manufacturing processes, standards, and applications of ERW pipes, shedding light on their significance in construction, infrastructure, oil and gas, and other sectors.

1.Introduction to ERW Pipes

ERW pipes are steel pipes manufactured through the process of electric resistance welding, which…

Explanation of Common Defects in ERW Welded Pipes

Explanation of common defects in ERW welded pipes:

Undercut

Undercut is a groove that appears along the centerline of the weld in the transition area between the edge of the weld and the pipe body. Undercut occurs when welding speed, current, voltage and other conditions are not properly matched.

lap welding

The upper and lower edges of the steel plate are misaligned and butted, resulting in uneven welds, which become pipe seam misalignment or…

The Differences Between ERW and Seamless Steel Pipes

The Differences Between ERW pipes(https://www.eastern-steels.com/products/erw-steel-pipe.html) and Seamless Steel Pipes(https://www.eastern-steels.com/products/carbon-steel-seamless-line-pipe.html)

Steel pipes are used in a wide range of applications, from oil and gas pipelines to structural steel and more. Two of the most common types of steel pipes are ERW pipes and seamless pipes. While both types of pipes are made from high-quality steel, there are some significant differences between the two. In this article, we will explore the differences between…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Performance Comparison of ERW and Spiral Steel Pipe

Performance comparison of carbon ERW steel pipe and spiral steel pipe:

1. Overview

The welding of ERW steel pipe is the skin effect and proximity effect of high-frequency current. The process of using high-frequency current and induced high-frequency current (rising at the end of the 20th century) resistance to heat and melt the edge of the tube blank, and apply squeezing force to weld together process.

The welding of SSAW steel pipe is…