Press release

Lee Spring acquires Clark Spring & Manufacturing

Lee Spring, a global leader in stock and custom springs, recently announced that it has purchased the assets of Clark Spring located in Hayward, California.Steve Kempf, CEO of Lee Spring, commented that “President of Clark Spring, Eric Eckberg, has built a strong company over the last thirty years based on ongoing engineering support, excellent quality control and attentive customer service. This fits our culture perfectly and adds significantly to our customer presence in California. We both believe this acquisition will help serve Clark Spring’s customers with expanded spring capabilities and products.”

Eric Eckberg stated that "The choice of selecting the right buyer for our business was critical to us. We were looking for a family owned company run by spring professionals that would carry on the engineering and quality that our customers have come to expect. I am pleased to be assisting with an orderly transition that will maintain our outstanding customer service.”

Jim Callaghan, Vice President Business Development of Lee Spring, stated "We are very pleased that Clark Spring is our first acquisition. As Lee Spring grows through strategic acquisitions, we are receiving interest from other companies that want to see their hard work continued by a long standing company and known leader in the spring industry.”

Further information on Lee Spring products can be found on their website - www.leespring.co.uk or follow them on twitter - https://twitter.com/leespringuk.

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

In addition, Lee Spring offer extensive custom design and manufacture services for one-off/prototypes or ongoing production requirements.

Lee Spring Ltd

Latimer Road

Wokingham

Berkshire, RG41 2WA

Tel: 0118 978 1800

email: sales@leespring.co.uk

www.leespring.co.uk

Press contact: Christopher Petts

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lee Spring acquires Clark Spring & Manufacturing here

News-ID: 337299 • Views: …

More Releases from Lee Spring Ltd

New website – New Online store – customers can now shop for Lee Spring parts …

Market leaders Lee Spring are delighted to provide their customers with the opportunity to buy online with full account management and basket purchasing facilities on their new easy to navigate website at www.leespring.co.uk – a fast ecommerce experience with highly efficient product search and CAD downloads.

Lee Spring offer over 25,000 stock spring designs on this site - ready to ship today with pricing and detailed specifications easy to view. These…

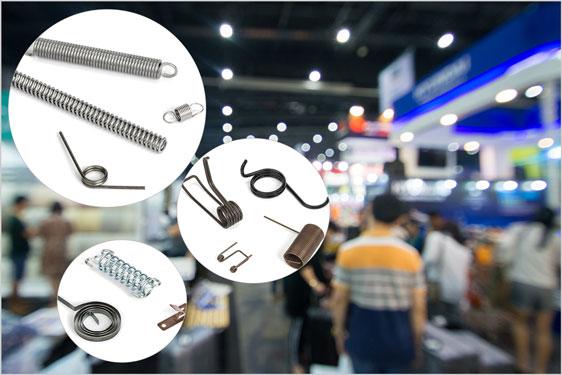

Lee Spring at Southern Manufacturing & Electronics Exhibition, Farnborough, 11-1 …

This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring. Lee Spring has recently expanded their UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products here in…

Exotic alloys - Lee Spring explain what they are and when to use them

Materials with high alloy content, known as super alloys or exotic alloys, offer enhanced performance properties including excellent strength and durability, and resistance to oxidation, corrosion and deforming at high temperatures or under extreme pressure. Because of these properties, super alloys make the best spring materials for demanding working conditions, which can be encountered across various industry sectors, including the Automotive, Marine and Aerospace sectors as well as oil and…

REDUX™ Wave Springs from Lee Spring – an enabling technology

Lee Spring REDUX™ wave springs offer a way of performing a spring function in minimal spaces – even perhaps where no other spring could work effectively. Typically, REDUX wave springs occupy just 30-50% of the compressed height space of the conventional round wire springs, yet they offer more deflection with the same load specifications. This not only helps to save space in the applications but also reduces the production costs,…

More Releases for Industrial

Industrial Display Market: Technology Advancements Driving Industrial Visualizat …

In recent years, the global Industrial Display Market has transformed significantly, driven by evolving consumer preferences, rapid technological advancements, and an increasing focus on sustainability. Our comprehensive Industrial Display Market Research Report is your essential guide to navigate this dynamic landscape, offering actionable insights into emerging trends, growth drivers, and key opportunities for your business.

Unlock in-depth analyses of the competitive supplier landscape, demand dynamics, and market projections with…

Industrial Display Market: Technology Advancements Driving Industrial Visualizat …

In recent years, the global Industrial Display Market has transformed significantly, driven by evolving consumer preferences, rapid technological advancements, and an increasing focus on sustainability. Our comprehensive Industrial Display Market Research Report is your essential guide to navigate this dynamic landscape, offering actionable insights into emerging trends, growth drivers, and key opportunities for your business.

Unlock in-depth analyses of the competitive supplier landscape, demand dynamics, and market projections with…

Industrial Auction Services Market Auctioning Industrial Assets By 2030 | Heath …

The Report on "Industrial Auction Services Market" provides Key Benefits, Market Overview, Regional Analysis, Market Segmentation, Future Trends Upto 2030 by Infinitybusinessinsights.com. The report will assist reader with better understanding and decision making.

The industrial auction services market is a diverse and dynamic sector that encompasses a wide range of industries, including manufacturing, construction, automotive, and more. These services are utilized by companies looking to optimize their asset management, streamline operations,…

RDM Industrial Products - Laboratory and Industrial Furniture Supplier

RDM Industrial Products Inc. is one of the most reputed and leading laboratory and industrial furniture solutions supplier and manufacturer. The company was established in 1977 and has been serving their growing clientele proudly for over 40 years. Their quality products cater to industries including healthcare, electronics, biotechnology, laboratory, industrial and more. The company is based out of California and their shipments are done all across the globe. QUALITY-SERVICE-TIMING are…

Industrial Fasteners Market # industrial fasteners and supply # industrial faste …

An insightful study, titled “Global Industrial Fasteners Market” has been freshly broadcasted to the vast research repository of Market Research Reports Search Engine (MRRSE). The research study provides detailed comprehensions and forecasts future growth of the global market with an in-depth study of the factors impacting revenue growth throughout the mentioned forecast period. Further, a deep analysis on the major players from diverse regions is also present in the report.

Get…

Global Industrial PC Market To Reach Us$8,784.2 Mn By 2025: By Type - Panel Indu …

Researchmoz added Most up-to-date research on "Global Industrial PC Market To Reach Us$8,784.2 Mn By 2025: By Type - Panel Industrial PC, Box Industrial PC And Embedded Industrial PC" to its huge collection of research reports.

Industrial PC is a ruggedized system designed to perform computing applications for various industries. Industrial PC is a PC-based computing podium mainly used for data acquisition or process control, and in some cases, it is…