Press release

Extensive range of torsion springs from Lee Spring

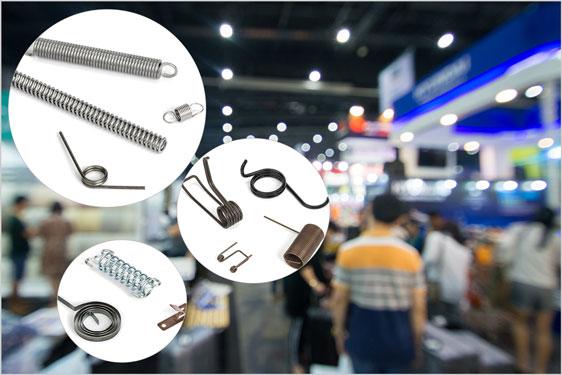

The extensive range of Lee Spring torsion springs catalogued for ex-stock delivery covers industrial applications from electronic devices such as pop-up covers on CD players, cameras etc., through counter balanced instrumentation covers, to ubiquitous items such as clothes pegs, garage doors or chair controls.Free position of torsion spring legs is selectable at order stage between 90°, 120°, 180°, 210°, 270°, 300° and 360°, as is direction of winding LH or RH so that forces may be correctly designed to wind up the spring, so permitting design engineers optimal choice for their application. Lee Spring torsion springs are designed with tolerances to allow use with a supporting mandrel.

Specialist miniature torsion springs are available with an outside diameter from 2.62mm, through to full sized units of over 50mm. These are covered by huge depth of stock at Lee Spring which ensures rapid one-off order delivery and timely production scheduling, in music wire or 302 stainless steel.

Torsion springs are such a widely recognised solution for control of mechanical devices that custom requirements are routinely met by the design engineering team at Lee Spring – who also supply a variety of kits. Kits of music wire or stainless steel torsion springs enable design engineers to evaluate prototype requirements and for maintenance specialists to deal with urgent repair situations.

Further information on Lee Spring products can be found on their website - www.leespring.co.uk or follow them on twitter - https://twitter.com/leespringuk.

Lee Spring is the UK supplier of choice for catalogued and custom springs, including compression springs, torsion springs, constant force springs, die springs, belleville spring washers, wave springs, extension springs, battery springs and numerous speciality springs. Materials include steel, stainless steel, cobalt/nickel alloy, bronze, brass, music wire and composite plastics.

In addition, Lee Spring offer extensive custom design and manufacture services for one-off/prototypes or ongoing production requirements.

Lee Spring Ltd

Latimer Road

Wokingham

Berkshire, RG41 2WA

Tel: 0118 978 1800

email: sales@leespring.co.uk

www.leespring.co.uk

Press contact: Christopher Petts

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Extensive range of torsion springs from Lee Spring here

News-ID: 332472 • Views: …

More Releases from Lee Spring Ltd

New website – New Online store – customers can now shop for Lee Spring parts …

Market leaders Lee Spring are delighted to provide their customers with the opportunity to buy online with full account management and basket purchasing facilities on their new easy to navigate website at www.leespring.co.uk – a fast ecommerce experience with highly efficient product search and CAD downloads.

Lee Spring offer over 25,000 stock spring designs on this site - ready to ship today with pricing and detailed specifications easy to view. These…

Lee Spring at Southern Manufacturing & Electronics Exhibition, Farnborough, 11-1 …

This year at Southern Manufacturing Exhibition, engineers and buyers seeking expertise in spring technology will be able to talk directly with the technical experts at Lee Spring. Lee Spring has recently expanded their UK manufacturing operations with the acquisition of Longcroft Engineering located in Lancashire between Manchester and Leeds. This acquisition provides Lee Spring with additional resources and capabilities to engineer and manufacturer a wider range of products here in…

Exotic alloys - Lee Spring explain what they are and when to use them

Materials with high alloy content, known as super alloys or exotic alloys, offer enhanced performance properties including excellent strength and durability, and resistance to oxidation, corrosion and deforming at high temperatures or under extreme pressure. Because of these properties, super alloys make the best spring materials for demanding working conditions, which can be encountered across various industry sectors, including the Automotive, Marine and Aerospace sectors as well as oil and…

REDUX™ Wave Springs from Lee Spring – an enabling technology

Lee Spring REDUX™ wave springs offer a way of performing a spring function in minimal spaces – even perhaps where no other spring could work effectively. Typically, REDUX wave springs occupy just 30-50% of the compressed height space of the conventional round wire springs, yet they offer more deflection with the same load specifications. This not only helps to save space in the applications but also reduces the production costs,…

More Releases for Torsion

Global Ring-torsion Load Cell Market Outlook Report 2025

"Global Ring-torsion Load Cell Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" is published by Global Info Research. It covers the key influencing factors of the Ring-torsion Load Cell market, including Ring-torsion Load Cell market share, price analysis, competitive landscape, market dynamics, consumer behavior, and technological impact, etc.At the same time, comprehensive data analysis is conducted by national and regional sales, corporate competition rankings, product types and…

Digital Torsion Testing Machine Market Sales and Growth Report

The Digital Torsion Testing Machine market research report is proficient and top to bottom research by specialists on the current state of the industry. This statistical surveying report gives the most up to date industry information and industry future patterns, enabling you to distinguish the items and end clients driving income development and benefit. It centres around the real drivers and restrictions for the key players and present challenge status…

Automotive Torsion Bar Market Research, Agency, Business Opportunities by 2028

An exclusive Automotive Torsion Bar Market research report provides depth analysis of the market dynamics across five regions such as North America, Europe, South America, Asia-Pacific, Middle East and Africa. The segmentation of the market by type, application, and region was done based on the thorough market analysis and validation through extensive primary inputs from industry experts, key opinion leaders of companies, and stakeholders) and secondary research (global/regional associations, trade…

Global Torsion Testers Market Analysis by 2020-2025

Scope of the Report:

The global Torsion Testers market size is expected to gain market growth in the forecast period of 2020 to 2025, with a CAGR of xx%% in the forecast period of 2020 to 2025 and will expected to reach USD xx million by 2025, from USD xx million in 2019.

Market segmentation

Torsion Testers market is split by Type and by Application. For the period 2015-2025, the growth among segments…

Torsion Test Machines Market Size, Share, Development by 2025

LP INFORMATION recently released a research report on the Torsion Test Machines market analysis and elaborate the industry coverage, current market competitive status, and market outlook and forecast by 2025. Moreover, it categorizes the global Torsion Test Machinesmarket by key players, product type, applications and regions,etc.

The main objective of this market research is to help the readers understand the structure of Torsion Test Machinesmarket, market definition, overview, industry opportunities…

Torsion Tester Market to Set Phenomenal Growth by 2028

Torsion Tester Market: Introduction

Twisting of an object caused due to the application of torque is known as torsion. Under the torsion shear stresses are produced which might result into breaking of the object. Torsion testers are also known as torque testing equipment. Torsion testers are used for the measurement of the torsional strength, stress strain characteristics and stiffness of materials and objects. Torsion tester is mainly used for the simulation…