Press release

Alternative: Stud-Welding

Increased productivity and flexibility for the installation of pipe, tube, hose and cable clampsIn many areas, stud welding is considered to be the most economic fastening method for components and is sometimes even the only technically feasible solution. Because the stud is joined with the substructure over the entire surface of the stud without any hollow areas, a high strength of the joint can be achieved.

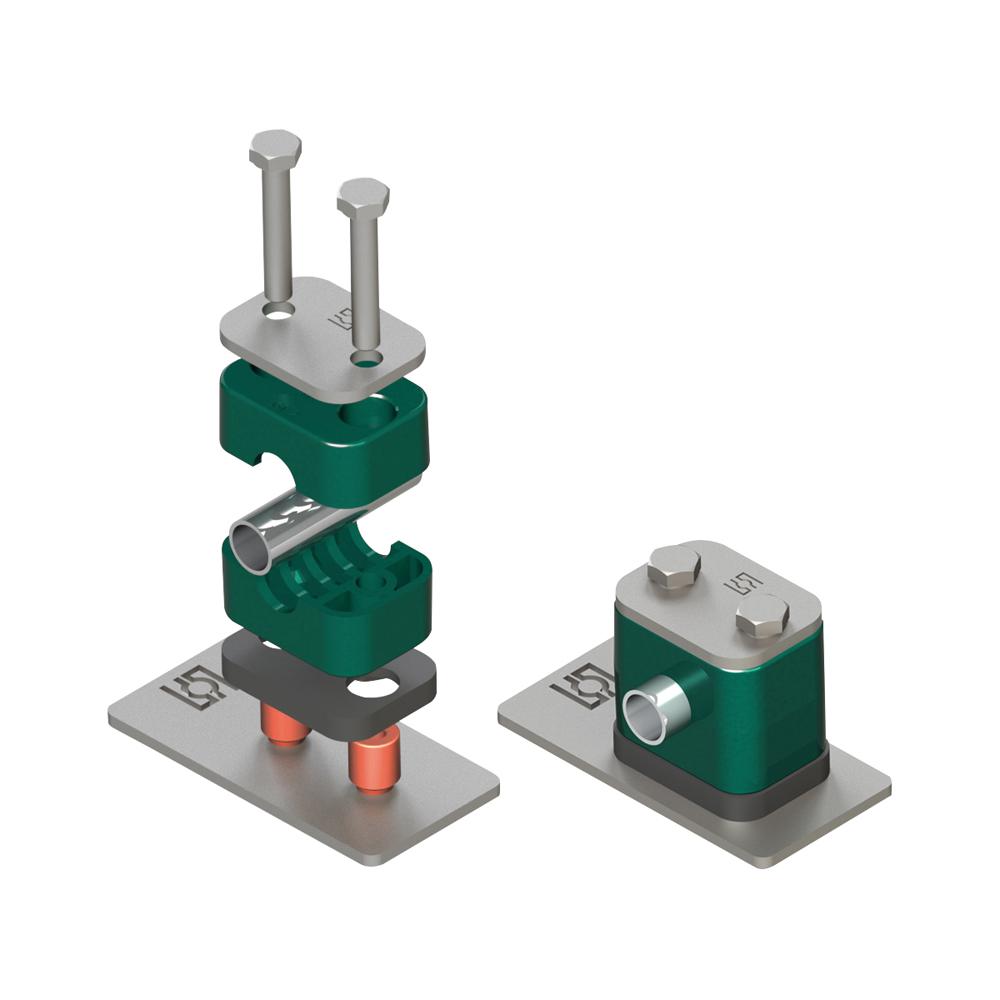

Stauff is now using this proven principle for the installation of pipe, tube, hose and cable clamps in the Standard Series (according to DIN 3015, part 1) with M6 mounting thread, where female threaded weld studs replace the regular weld plates; distance plates made from plastic provide the necessary spacing between the clamp bodies and the substructure. If required, the system can also be adopted for alternative fastening methods, e.g. for clamping belts, cable ties or corrugated cable protection hoses.

In addition to the individual components – weld studs, distance plates, clamp bodies and metal hardware required – the company also provides the correspondingly designed assembly tools such as the weld inverter and the weld gun with tripod, weld stud retainer and distance adaptor. The lightweight and compact weld inverter works without high-voltage current.

Thanks to increased productivity and flexibility for the installation of clamps, the system offers considerable savings potentials for users with significant processing volumes, especially when working in horizontal or overhead position. The amount of rework on welding locations can be significantly decreased, and material distortion is reduced to a minimum through low thermal stress.

The joint of the weld stud with the substructure impresses in particular with a high degree of strength and safety, which is at least at the same level as for regular weld plates.

For more than 50 years now, the STAUFF Group with headquarters in Werdohl (Germany) has been successful in the development, manufacturing and distribution of pipework equipment and hydraulic components for mechanical and plant engineering as well as for service and industrial maintenance. The overall product range currently includes about 33,000 standard products as well as numerous special and system solutions according to customer requirements or based on own developments.

Wholly-owned manufacturing, sales and service facilities with more than 1,150 employees in 18 countries and a tight network of authorised distributors and representatives in all major industrial regions of the world ensure high presence and service paired with a maximum of availability.

In April 2015, VOSWINKEL was acquired and became a member of the STAUFF Group. With two sites located in Meinerzhagen (Germany) and 230 employees, VOSWINKEL is considered to be one of the world's five largest producers of quick release couplings for hydraulic systems. The long-established company also develops and produces a comprehensive range of hydraulic hose fittings – particularly for high-pressure applications – as well as custom-designed piping, primarily for construction and agricultural machinery as well as for commercial vehicles.

In 2015, the companies of the STAUFF Group have generated external sales revenue totalling EUR 230 Mio.

Press Contact

Walter Stauffenberg GmbH & Co. KG

Mr Boris Mette

Im Ehrenfeld 4

58791 Werdohl

Phone: +49 (0) 2392 / 916-154

Telefax: +49 (0) 2392 / 916-270154

eMail: b.mette@stauff.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Alternative: Stud-Welding here

News-ID: 326368 • Views: …

More Releases for STAUFF

Voswinkel becomes part of the Stauff Group

(Meinerzhagen / Werdohl, Germany) As mutually announced by both companies, the Stauff Group has successfully completed the acquisition of the Meinerzhagen, Germany based company Voswinkel from the Voswinkel shareholder family in April this year already.

With corporate headquarters in Werdohl, Germany and two additional plants in Plettenberg-Ohle and Neuenrade-Küntrop, the Stauff Group develops, manufactures and distributes pipework equipment and hydraulic components for mechanical and plant construction as well as for…

Updated Stauff One product catalogue available

Updated Stauff One product catalogue available

Pipework components, test equipment and hydraulic accessories from a single source

Beginning in February 2014, the new, revised and in some areas significantly expanded general product catalogue will be available from Stauff, the Werdohl, Germany based fluid technology specialist.

On a total of 682 pages, the so-called Stauff One – initially released in spring 2011 – provides all relevant general, ordering and technical information about the company’s…

STAUFF trainee achieves best grade

Florian Kircher, previously trainee for the position of cutting mechanic with the subject area of automatic lathe systems at the Werdohl production plant of Walter Stauffenberg GmbH & Co. KG, has been named one of the best graduates in his training class. At a celebratory ceremony on 16 October, Mr Kircher, who this year completed his vocational training before the testing committees of the South Westphalian Chamber of Industry and…

Withstanding Extreme Conditions - Stauff Clamps meet the requirements of Russian …

The Stauff Group have been suppliers to the rail industry for almost 35 years, the first project starting in the 1970s with Stauff UK supplying clamping components and systems to the Metropolitan Cammell Carriage and Wagon Company (MCCW), a former Birmingham, England based manufacturer of railway carriages and wagons. Original STAUFF clamps were used for trains on the Jubilee Line of London's underground railway system, which was officially opened on…

Stauff clamps assure safe installation of hydraulic hoses

Stauff provides a range of products that assures your hydraulic system operates safely and in a secure environment for components. Stauff clamps are applied to many industrial hydraulic applications and although the standard ribbed option is prominent in fixed-pipe systems, the use of the PPH smooth bore range offers unique advantages to the safe clamping and supporting of hydraulic hose. Hose is an integral component in a hydraulic system…

Bring on the water: Stauff industrial filters

For the first time, the German fluid power specialist Stauff will be presenting an independently developed solution for the filtration of industrial water at the Hanover trade fair in April 2013. The SRFL-SW single filter housings have been designed to be used in the steel industry for pre-filtering or coarse filtering in descaling plants.

The SRFL-SW series was developed and designed for direct installation into the pipelines of industrial water…