Press release

The new digital piezo controller d-Drive pro

piezosystem jena presents the d-Drive pro, the latest generation of digital control electronics for piezo actuators. These piezoelectric ceramic based actuating systems and piezo stages are mainly used for micro and nano positioning for a highly accurate movement of optical devices and optical components.The new piezo controller d-Drive pro of piezosystem jena provides 24 bit resolution and simultaneous regulation of 3 axes with an internal data transfer rate of 50 kHz. The d-Drive pro has a compatible instruction set to that of the existing d-Drive® series. As with the standard d-Drive® all digital piezo actuators can be controlled via PC. The d-Drive pro also shares the same great features including: freely programmable frequency generator, adjustable slew-rate, as well as notch and low pass filters. The d-Drive pro also allows for the exchanging of actuators in the field through Automatic Sensor Identification (ASI) and Automatic Sensor Calibration (ASC). The new integrated Field Programmable Gate Array (FPGA) offers the users of the d-Drive pro entirely new possibilities with the highest flexibility.

Special highlights include the high 24 bit resolution and simultaneous control of up to 3 axes. The interfaces available to the user are RS232, USB and Ethernet as well as an analog modulation input and monitor output.

New functions like curve tracking or temperature monitoring complete the d-Drive pro and enable new applications for daily use. The output current of a single axis is adjustable up to 300 mA.

We will be happy to help you to find a solution for your application.

For further information on the d-Drivepro, please visit www.piezosystem.com or email info@piezojena.com.

piezosystem jena is a worldwide supplier of high precision piezo positioning equipment. Our piezoelectric ceramic based actuating systems and piezo stages are mainly used for micro and nano positioning for highly accurate movement of optical devices and optical components.

piezosystem jena GmbH

Stockholmer Str. 12

07747 Jena

phone: +49 (3641) 66 88 0

fax: +49 (3641) 66 88 66

e-mail: info@piezojena.com

piezosystem jena, Inc.

2B Rosenfeld Drive

Hopedale, MA 01747

USA

phone: +1 508 634 66 88

fax: +1 508 634 68 68

e-mail: usa@piezojena.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The new digital piezo controller d-Drive pro here

News-ID: 289027 • Views: …

More Releases from piezosystem jena GmbH

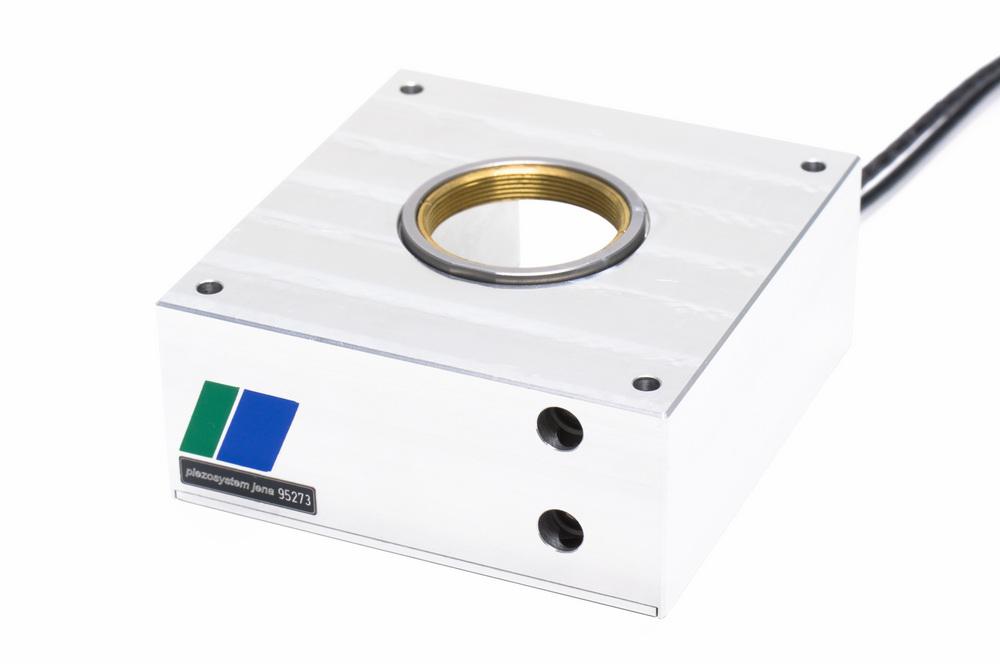

Objective Positioners Adapted To Meet Your Needs For Industrial Applications

piezosystem jena has extended the objective positioner series MIPOS with two new industry products.

Typically objective positioners are firmly mounted directly onto a microscope. Piezosystem also introduces two new systems, which can be screwed on a machine or rail.

MIPOS 140:

Most installed lens positioners require an undesired extension to the optical axis. The distance between the lens and the sample is shortened. This can lead to collisions between the optics and the…

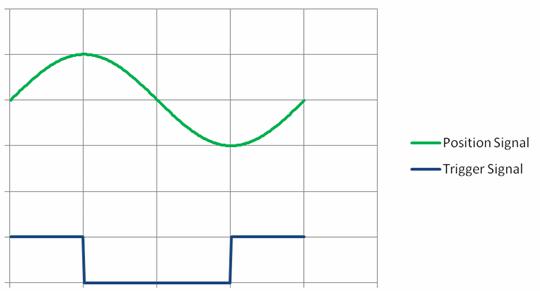

Incremental Trigger Function

Trigger signals dependent on the position of the stage

Digital piezo-controllers from piezosystem jena (d-Drive and d-Drivepro) offer flexible control for customized systems such as cameras, illumination systems, optical shutters or external measuring systems.

Now, piezosystem jena can offer a comfortable trigger function.

Trigger signals can be generated dependent on the position of the stage:

• Rising edge

• Falling edge

• On both edges in the direction of movement

An additional function sends out a trigger…

New Product-Catalog from piezosystem jena

Positioning Solutions with Sub-Nanometer-Precision; Movements up to Multiple Centimeters/ Inches

piezosystem jena introduces its brand-new catalog! To offer you complete systems for your needs, piezosystem jena has engineered and produced a NEW series of Motion Control Stages and High-Power Piezo-Composite Actuators.

The new catalog does not only show our proven, ultra-precise nanopositioning piezo stages for positioning with sub-nanometer accuracy and their appropriate controllers; it also incorporates our powerful Piezo-Composite Actuators and their…

Beam Tracking with Mirror Tip- and Tilting Piezostage PKS1

In biology applications a laser beam is used for cell stimulation. First the laser beam is redirected onto 2 mirrors then directed to the cells. An important requirement, to hold the laser beam onto the cell is very difficult to achieve due to thermal effects or external vibration. The position of the laser beam needs to be controlled in real-time to track the motion of the cell.

For this task a…

More Releases for Drive

Harmonic Drive Gearbox Market 7.50% CAGR Growth with GAM Cone Drive Datorker Sch …

The Harmonic Drive Gearbox market is poised for significant growth in the coming years, driven by the increasing demand for precision motion control across various industries. This specialized gearbox is known for its unique design, which allows for high torque transmission, compact size, and exceptional accuracy. These attributes make Harmonic Drive Gearboxes particularly attractive for applications in robotics, aerospace, medical devices, and industrial automation. As industries continue to advance toward…

Dream Drive Brings Self-Drive Car Rental Services to Ranchi

Ranchi, Jharkhand - Dream Drive, Ranchi's newest and most trusted self-drive car rental service, is redefining the way people travel in the city. With a fleet of brand-new, well-maintained cars, Dream Drive offers customers the freedom to drive on their own terms at affordable rates.

From compact hatchbacks to spacious SUVs and premium sedans, Dream Drive has a car for every occasion - whether it's a family outing, business trip, wedding,…

Electric Axle Drive And Wheel Drive Market Size Analysis by Application, Type, a …

USA, New Jersey- According to Market Research Intellect, the global Electric Axle Drive And Wheel Drive market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The growing popularity of electric vehicles (EVs) and improvements in drivetrain technologies are propelling the market for electric axle drive and…

Harmonic Drive Market to Witness Stunning Growth | Major Giants Harmonic Drive S …

HTF MI recently introduced Global Harmonic Drive Market study with 143+ pages in-depth overview, describing about the Product / Industry Scope and elaborates market outlook and status (2024-2032). The market Study is segmented by key regions which is accelerating the marketization. At present, the market is developing its presence. Some key players from the complete study are Harmonic Drive Systems Inc., Sumitomo, Cone Drive, Beijing CTKM, ABB, Nabtesco.

Download Sample Report…

Global Land Top Drive Market 2020, Land Top Drive Market, Land Top Drive Market …

Global Land Top Drive Market Growth 2020-2025 released by MarketandResearch.biz embarks with industry overview which clarifies value chain structure, industrial environment, market size, market share, regional analysis, application, and forecast. The report outlines the development factors improving or hampering the market advancement, major ruling organizations, monetary circumstance, and veritable certainties. This research is exceptionally advantageous to pursuers. This research refines variations of the global Land Top Drive market to help…

Harmonic Drive Market Forecasts – HDSI, Leaderdrive, Beijing CTKM Harmonic Dri …

For overview analysis, the report introduces Harmonic Drive Market basic information including definition, classification, application, industry chain structure, industry overview, policy analysis, and news analysis, etc.

Harmonic Drive Market :

Harmonic Drive is a compact, high performance, precision reduction gear. It is one of the key components used in robotic products such as collaborative work robots. The gear consists of only 3 basic parts (Wave Generator, Flex spline, and Circular Spline). It…