Press release

ENGMATEC at APEX Expo - test system with wireless interface

For the first time ENGMATEC will be represented this year at a trade fair in the USA. In cooperation with Landrex Technologies the German company will exhibit at the APEX Expo, the premier event for the electronic industry.The technical conference and exhibition will be held from 25 to 27 March 2014 at the Mandalay Bay Resort & Convention Center, Las Vegas. Thousands of industry professionals from more than 50 countries attend this exhibition - featuring advanced and emerging technologies in printed board design and manufacturing, electronics assembly, test and printed electronics.

ENGMATEC wants to present its wide range of services increasingly to an international clientele.

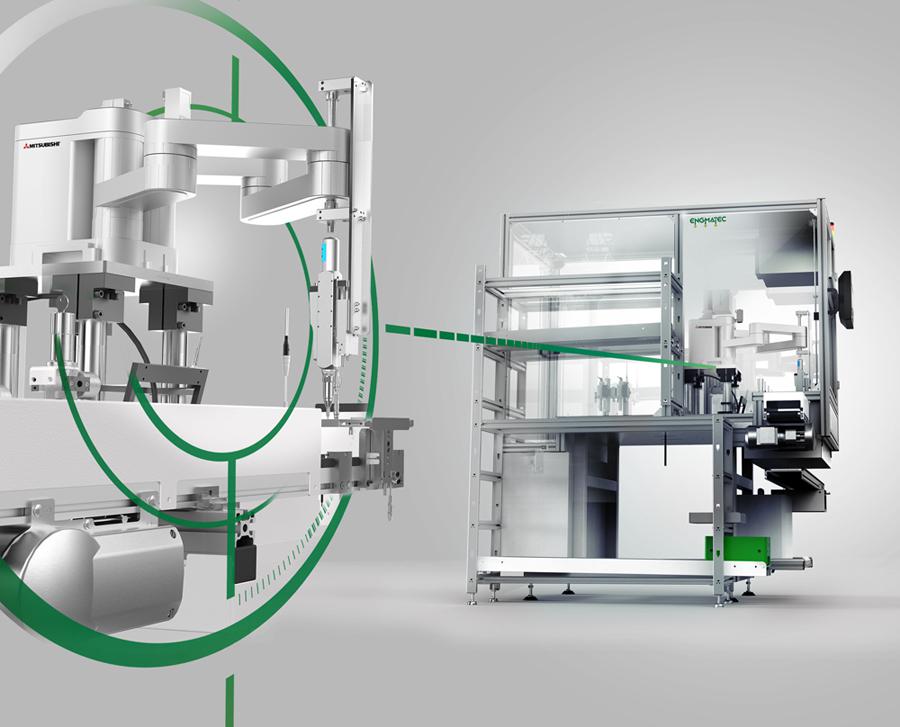

For example, visitors will get information about an inline test system for incircuit and functional tests with wireless interface.

On request of the Boston company Teradyne, a test handler was developed where the test system, the power supplies and the control PCs are completely inside the equipment. The very compact design allows extremely space-saving use of the equipment. In this innovative solution, the test system "TSi" from Teradyne is positioned directly below the contacting unit on a lifting unit with firmly screwed "link modules" connecting the test system by a pneumatic lift with the horizontal interface of the test adapter. Contrary to competitive products, no cabling is required.

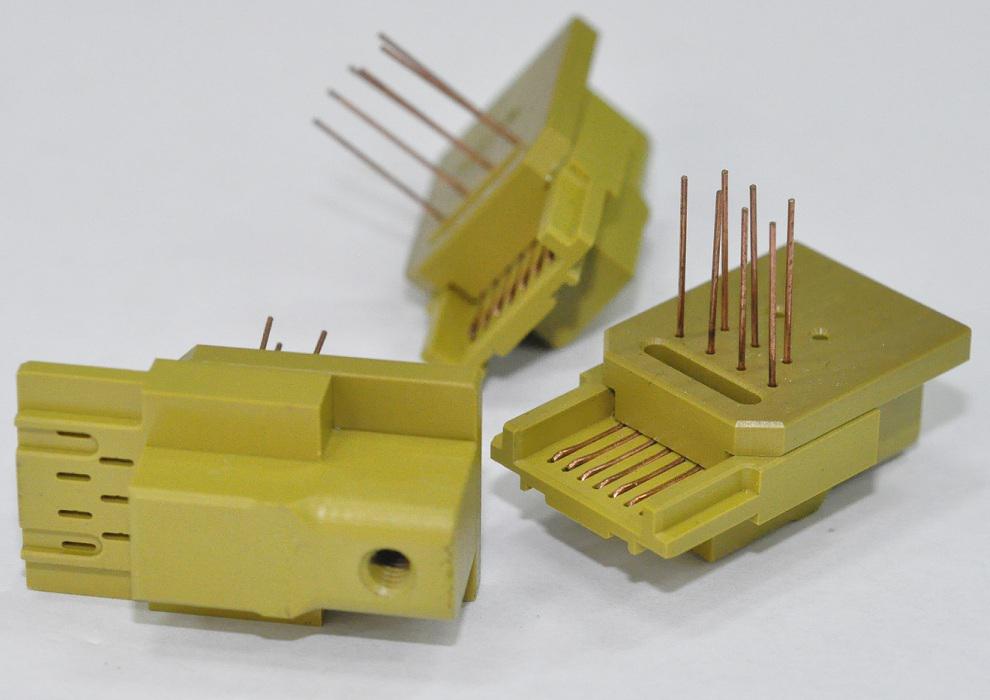

Additionally, ENGMATEC will inform you on its delivery program for test plugs. The company from Lake Constance produces industry-standard, highly wear-free contacting connectors for testing the most commonly used interfaces.

You find ENGMATEC at booth number 973.

ENGMATEC’s central business area is the development and production of systems in the field of assembly automation and testing technology.

The automation division comprises completely and partially automated production lines, rotary index tables, robotics, stand-alone stations and handheld devices. In addition to the assembly mounting the systems are often equipped with integrated measurement and test systems. Our special strength lies in the combination of automated or manual assembly processes with professionally integrated end-of-line test technology.

The field of measuring and test equipment includes standard modules for in circuit test and functional test (test adapters, test fixtures, in-line test systems), temperature testing systems

(Burn-In, HALT / HASS, Life Test, Calibration) and test plugs.

In addition, an extensive board handling program for printed circuit boards, soldering frames and workpiece carriers complements the product range: (conveyors, PCB loader/unloader, handling systems, buffers, marking- and recognizing-units).

The company, based at Lake Constance, covers the full spectrum of services from design to service and maintenance.

ENGMATEC GmbH

Fritz-Reichle-Ring 5

78315 Radolfzell

Germany

www.engmatec.de

Presscontact:

Sabine Vormbaum

phone: +49(7732) 9998 23

fax : +49(7732) 9998 13

Sabine.Vormbaum@engmatec.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release ENGMATEC at APEX Expo - test system with wireless interface here

News-ID: 284292 • Views: …

More Releases from ENGMATEC GmbH

Board handling with AGV at productronica

At this year's productronica in Munich, the automation specialist ENGMATEC presents a test line with test handler and board handling. This time a 2-fold loader/unloader module will be used for handling the PCB magazines. The board handling module has a corresponding interface to be supplied with magazines via a Automated Guided Vehicle (AGV). Loading and unloading takes place autonomously by the AGV. In the trade fair constellation, the control of…

High-speed screwing system from Engmatec at the Motek

Radolfzell, Germany, 02.09.2014

At this year’s Motek trade fair to be held from 6-9 October 2014 in Stuttgart, Mitsubishi Electric together with Engmatec GmbH will be presenting a high-speed screwing station for inline operation as part of an assembly line. Within the system, a Mitsubishi Electric dual-arm SCARA robot from the RP series performs the handling and tightening of the screws using a vacuum suction unit. The compact system can handle…

Engmatec GmbH expands its management

On October 1, 2012, Thomas Lang was appointed to the management of ENGMATEC GmbH.

Thomas Lang supports Josef Engelmann of the management board and is, along with Maria Engelmann, a shareholder of ENGMATEC GmbH. He is responsible for the areas sales, project planning and control engineering.

The specialists for test engineering and automation from Lake Constance thus set the course for a successful future. They send a clear signal for the strategic…

New testplug for SATA interfaces from ENGMATEC

For testing eSATA interfaces specially designed test plugs are available from ENGMATEC in Germany. Serial-ATA, short SATA is a worldwide established interface for hard disks and interchangeable data mediums.

End-of-line testing of electronic equipment is becoming increasingly significant as an important component of modern testing strategies. SATA interfaces are especially used in the consumer and entertainment electronics and also gets more important in the fields of automotive and industrial electronics.

Industrial-strength test…

More Releases for Inline

Inline Density Sensors Market Research Report

Global Inline Density Sensors Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031

According to our (Global Info Research) latest study, the global Inline Density Sensors market size was valued at US$ 298 million in 2024 and is forecast to a readjusted size of USD 447 million by 2031 with a CAGR of 6.1% during review period.

Global Info Research's report offers key insights into the recent developments…

Inline Moisture Sensors Latest Market Report 2025

Global Info Research announces the release of the report "Global Inline Moisture Sensors Market 2025 by Manufacturers, Regions, Type and Application, Forecast to 2031" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets.…

Why Should One Get An Inline Checkweigher System?

An inline checkweigher system [https://www.sgcheckweigher.com/checkweigher-1/] is a crucial investment for any production line due to its ability to provide real-time, accurate weight measurements of products as they move through the line. inline checkweigher systems [https://www.sgcheckweigher.com/checkweigher-1/] are designed to check the weight of your products directly in your production lines without having to stop them. They present many advantages for the control of prepackaged goods, missing products and tolerance checks. Here…

Inline Viscosity Sensors Market 2021 | Detailed Report

According to Market Study Report, Inline Viscosity Sensors Market provides a comprehensive analysis of the Inline Viscosity Sensors Market segments, including their dynamics, size, growth, regulatory requirements, competitive landscape, and emerging opportunities of global industry. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC, Tables and Figures) of Inline Viscosity Sensors Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5048562

The report provides a…

Inline AOI Systems Market - Growth of Inline Aoi System Market Is Boosted By Inc …

Automated optical inspection (AOI) is a process of visual inspection which is operated automatically to detect different manufacturing defect such as catastrophic failure and quality defect. This technology is adopting by different types of manufacturer such as printed circuit board manufacturing, liquid - crystal display (LCD) manufacturing, transistor manufacturing, others. Moreover, AOI systems has been segmented in two types such as desktop AOI and Inline AOI systems. Inline AOI…

New ParticleTrackTM E25 provides accessible inline characterization

A new inline characterization tool from METTLER TOLEDO provides a simple, effective method for robust in situ aqueous chemistry particle system tracking, helping to enhance optimization and reduce quality control costs in labs and production environments across a wide range of industries.

METTLER TOLEDO is pleased to announce the launch of its new inline particle system characterization tool ParticleTrackTM E25. Modifying focused beam reflectance technology (FBRM®) for use in settings where…