Press release

Everybody be cool – A Comparison of Cooling Systems for High Pressure Pumps

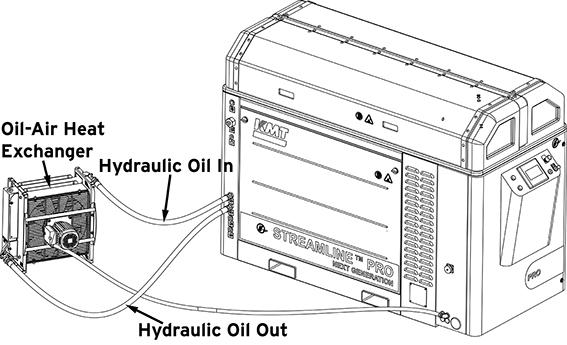

Which cooling system fits best for which high pressure pump installation for waterjet cutting? When operating a high pressure pump for waterjet cutting, it is crucial to run a reliable cooling system as some vital components of the pump may be damaged if the temperature of the hydraulic oil rises above a certain point. Therefore, KMT Waterjet high pressure pumps carry out an automatic shut-down as soon as the oil gets too hot. For its pumps, KMT recommends an operating temperature of 40-45°C (104-113°F). Concerning the cooling system, the company offers a few alternatives: Water cooler, air cooler or a combination of both. Which of these alternatives is the best one depends on the installation parameters of each individual waterjet cutting machine.To answer the question which of the alternative cooling systems is suitable for a particular waterjet cutting application, environmental influences as well as the installation conditions have to be taken into consideration. Basically, the air cooler only works reliably up to an ambient temperature of about 30°C (86°F): For the efficient operation of such a system, the ambient temperature has to be at least 10°C (50°F) cooler than the temperature of the hydraulic oil. If the thermometer rises above this value, the cooling power decreases rapidly. Indeed, the high pressure pump still runs at higher temperatures – the automatic shut-down does not occur until the oil reaches 62°C (144°F); however, exceeding the recommended maximum temperature may have a negative effect on the lifetime of the high pressure seals in the intensifier.

Advantages of the Air Cooler

Anyway, the air cooler has its advantages, too. The water cooler as the standard option for KMT STREAMLINE high pressure pumps may be slightly cheaper in the initial purchase, however, this price advantage is quickly put into perspective: If a water cooler is installed without an additional chiller for the cooling water, further operating expenses are incurred as the water directly goes to the drain after one turn in the cooling circuit,. A 50 hp high pressure pump for example can have a cooling water consumption of 10 l/min. Depending on water costs and running times, the system creates operational costs which can be avoided using an air cooler. These costs can be saved by reusing the water. To do so, the waterjet cutting machine operator has to connect an external chiller to cool down the used water before reintroducing it into the cooling circuit. Yet, the costs for such a chiller may actually amount to three times the additional costs of the air cooler. So considering the total costs, the air cooler is the more cost-effective alternative after all.

Regarding the installation effort, the air cooler also comes out front. This option provides the buyer with a ready-to-use system. In contrast, installing the water cooler necessitates either a set-up of the chiller or of the drain for the cooling water. So an air cooler is particularly advantageous for smaller waterjet cutting companies which have no access to an already existing cooling system. Additionally, the exit air from the air cooler can be used to heat up small buildings.

Advantages of the Water Cooler

A water cooler may pay off in case the high pressure pump operator can dispose of cheap water, for example a river or some other water bodies close to the location of the waterjet cutting machine. Additional costs still cannot be completely avoided though: When feeding the water cooler via a body of flowing or standing water, an additional pump probably becomes necessary to reach the minimum inlet water pressure of 2.5 bar.

However, in regions regularly and permanently reaching 30°C (86°F) ambient temperature or more, there is no alternative to a water cooler as the functionality of an air cooler meets its natural limitations. The same is true for large high pressure pump networks consisting of 4 to 5 or more machines. If air coolers are used in such cases, they will create air turbulences which may be more or less strong depending on the type of building and which delimit the cooling system’s efficiency. Additionally, the large amount of exit air created by the many systems heats up the environment and makes a cooling down just with air impossible.

What’s the best System?

To put it in a nutshell, the air cooler is the more cost-effective alternative compared to the water cooler regarding purchasing and operating costs, but it cannot be used in every circumstance. For high average ambient temperatures or large high pressure pump networks, water coolers are the more reliable option. The highest flexibility though is achieved with a combination system as KMT offers for its high pressure pumps. Particularly in regions with occasional temperature peaks of above 30°C (86°F), the cost-effective air cooler can be combined with the more reliable water cooler. In such a combination system, the air cooler is the main cooling system and the water cooler is switched on only if needed.

About KMT Waterjet Systems

KMT Waterjet Systems is a leading multinational manufacturer of components for waterjet cutting systems. The company develops solutions for a wide range of industries and applications. Since 1971 the company has been dedicated to long-term customer relationships. Continuous investment in innovation has made KMT Waterjet Systems the market leader in the waterjet cutting industry. High pressure pumps, cutting heads, abrasive systems, high pressure tubes, original spare parts and a global service network are among the key products and services of the company.

KMT GmbH

Ralf kleine Brörmann

Hohe Strasse 4-6

61231 Bad Nauheim

Deutschland

Phone: +49 (0) 6032 / 997-126

Fax: +49 (0) 6032 / 997-270

E-Mail: ralf.broermann@kmt-waterjet.com

Internet: www.kmt-waterjet.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Everybody be cool – A Comparison of Cooling Systems for High Pressure Pumps here

News-ID: 269599 • Views: …

More Releases from KMT Waterjet Systems

Quick and economical waterjet cutting with ABRALINE Advanced

(Bad Nauheim, 2013-02-06) With the ABRALINE abrasive bulk transfer system, KMT Waterjet Systems offers a solution to enable quick and economical waterjet cutting. The latest addition to this product line is the model version ABRALINE Advanced which features a larger abrasive silo and an optimized design. Thus, it is able to reliably feed demanding waterjet cutting applications. The use of such a system pays off: When cutting with a waterjet,…

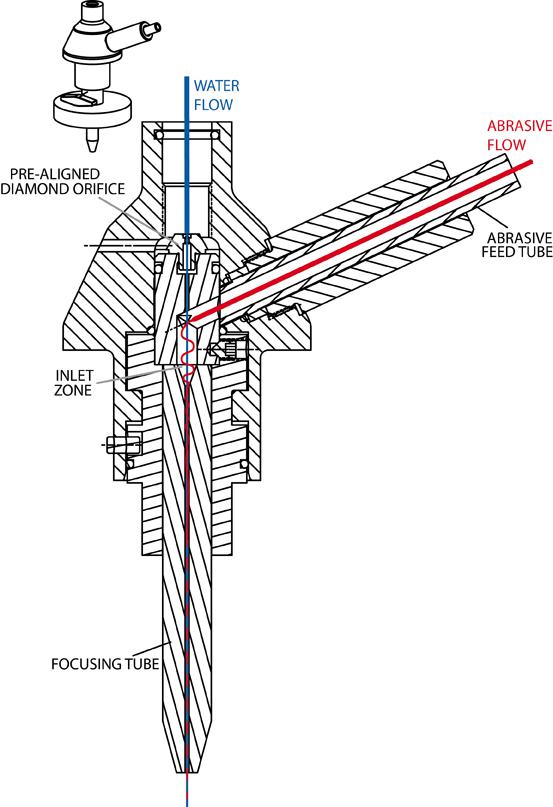

Focus on Abrasive Cutting

In the process of abrasive waterjet cutting, the focusing tube is a vital component. After all it is in this tube where high pressure water and abrasive are focused to an efficient cutting jet. During this procedure, the physical processes in the tube crucially affect the final speed and precision of the cutting jet as well as the kerf width at the workpiece. However, which factors influence the functionality of…

More Releases for Water

Water Trading Market Size in 2023 To 2029 | Severn Trent, Calgon Carbon, Murray …

The Water Trading report provides a comprehensive analysis of market drivers, limitations, and opportunities, offering a clear and comprehensive view of the market. It thoroughly evaluates market shares, strategies, products, certifications, regulatory approvals, patent landscape, and manufacturing capabilities of key players. The report also highlights the business manufacturing activities of major manufacturers, accompanied by relevant technical data. Additionally, the report presents a detailed overview of the competitive landscape of the…

water bikes market, global water bikes market, water bikes industry, water bike …

Prominent water bike manufacturers are focussing on product innovations for experience of the consumer and for that, strategic analysis, collaborations and mergers, joint acquisitions, product launched are done by these manufacturers for taking care of their leading positions in the water bikes industry.

Key Developments in Water Bikes Industry

In January 2020, World’s first hydro e-bike named as Hydrofoiler-XE1 by Manta 5 was launched. The bike doesn’t have wheels and instead it…

Mobile Water Treatment Systems market-Veolia Water Technologies, GE Water, Evoq …

Garner Insights recently released Global Mobile Water Treatment Systems Market research study with over 100 industry informative desk and Figures stretched through Pages and self-explanatory detailed TOC on “Mobile Water Treatment Systems Market”.

Global Mobile Water Treatment Systems market 2019 research assists you to attain positive growth and try out different methods for maximizing your profit. The market study gives estimates for Global Mobile Water Treatment Systems Market 2019 analysis and Forecast till 2025. Some…

Water Network Management, Water Network Management trends, Water Network Managem …

MarketStudyReport.com adds a new 2018-2023 Global Water Network Management Market Report focuses on the major drivers and restraints for the global key players providing analysis of the market share, segmentation, revenue forecasts and geographic regions of the market.

This report presents a comprehensive overview, market shares, and growth opportunities of by Water Network Management product type, application, key manufacturers and key regions. Over the next five years, Water Network Management will…

Bailley Drinking Water – Healthy Water – Safe Water

-Although water covers 70% area of Earth and it is the most necessary element for the survival, yet it is not available in abundance for drinking. Thus, Bailley turns out to be supplying high quality drinking water across India since its launch in 1993. Bailley packaged water is bottled in 52 state-of-the-art plants across India. Targeting various category of consumers & occasions, Bailey Water Bottle is satisfying their needs. There…

Mobile Water Treatment Market presents strong revenue visibility | Evoqua Water …

Global Info Reports render to you profound details in respect to leading participants, regions, application and type of the Mobile Water Treatment Market which is estimated to encounter substantial growth over the forecast period 2018-2025.

Market Outlook:

The market report based on our unique research methodology delivers thorough analytical scrutiny of the Global Mobile Water Treatment Market dispersed across several segments. The report also consists of current size and summary of the…