Press release

MIC – Microbially influenced corrosion / Anaerobe biocorrosion induced by SRB-bacteria

Anaerobic biocorrosion (MIC) causes much trouble in different sectors of industry. The anaerobic microorganisms provoke a 10-times higher corrosion rate by the release of specific enzymes (mainly ”hydrogenase”). Moreover, the bacteria produce toxic hydrogen sulfide. Only in Germany, MIC leads to losses in the amount of double-digit billions and to environmental damages of inestimable dimensions; 20% of all costs caused by corrosion are based on microbial destruction of the material.Mainly responsible for the anaerobic corrosion are sulfate reducing bacteria (SRB). These microorganisms accelerate corrosion in tanks and other technical installations, which come in contact with water and organic materials. Such surfaces have to be cleaned continuously; otherwise, gel-like biofilms form due to the rapid propagation of SRB bacteria. This process causes biofouling with a strong smell and slime formation which could be a precursor of biocorrosion.

Since years, various conferences, studies and examinations regarding this matter are conducted. Also many publications are released. The complex of problems is clearly identified and scientifically proven. But so far no long-run concept for the prevention of biocorrosion was generated. The removal of biofilm and biofouling, the killing of the bacteria with disinfectants or elimination of their life sources are not durably effective.

Unique long-term protection against biocorrosion

induced by SRB-bacteria!

Development and patent application by Ceramic Polymer GmbH!

An important part of our company philosophy is the new development of coating products for special demands. Through extensive and continuous research work, we are constantly improving the quality and the range of our product portfolio. Therefore we also provide adequate coating solutions for specific niche markets.

One of our multiannual research projects has been successfully completed. As the single manufacturer, Ceramic Polymer features internal coatings for biogas plants and storage tanks for crude oil and all kinds of hydrocarbons against anaerobic biocorrosion induced by SRB bacteria.

Perfomances and properties of the new anti-SRB-coating systems

Special biocides in nano-crystalline shape

are integrated by a patent pending method in a specific-micro-filled polymer matrix.

Unique functionality

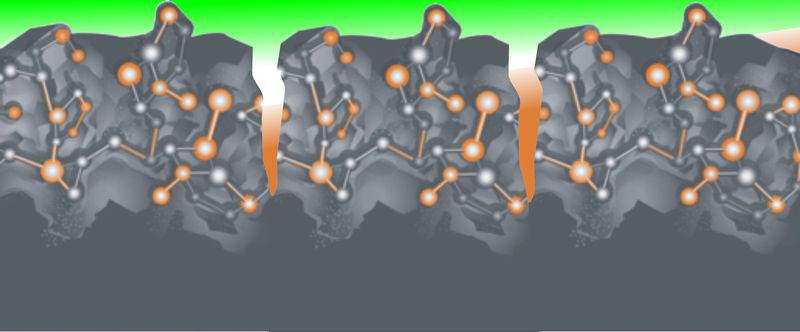

Due to temperature gradients or mechanical impact, cracks in the range of nano- or micrometers occur in every(!) coating during operation time. The SRB bacteria settle down primarily in those cracks, which appear as protective niches with low circulation.

As soon as micro cracks occur in the coating, the special biocide crystals burst and unfold their effect within the whole crack. The SRB are killed before they can settle. The existing depot effect causes a long-lasting biocidal corrosion protection without localized erosion.

No negative impacts occur to the necessary bacterial processes in biogas fermenters, because the biocidal effects are restricted locally to the micro cracks in the coating.

Safe application

During the application procedure and also after curing, the biocidal active component remains at first tightly encapsulated in the polymer matrix, so that the coated surface is not antiseptically active and therefore physiologically harmless. The kind of biocide employed is virtually harmless for humans. The application of these effective coating systems can easily be conducted by airless spraying method or roll and rake.

Constant durability

Extensive test series by our independent research partner have proven clearly that biocorrosion induced by SRB-bacteria can be largely prevented by using our special coating products. Therefore, effective and targeted protection of concrete and steel substrates for biogas plants and tanks for crude oil and hydrocarbons is permanently achieved.

The Ceramic Polymer GmbH produces high-performance coatings with integrated micro ceramic particles for different fields of application. The properties of the ceramic – chemical resistance, abrasion resistance and weathering stability – justify the high quality of our coating systems. By extra integration of microscopic special particles, we generate coating products which provide the highest protection properties.

Ceramic Polymer GmbH

Mrs. Stephanie Wuensch

Daimlerring 9

DE-32289 Roedinghausen / Germany

Phone: +49 80)5223 96276-0

Email:info@ceramic-polymer.de

Web: www.proguard-coatings.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release MIC – Microbially influenced corrosion / Anaerobe biocorrosion induced by SRB-bacteria here

News-ID: 268411 • Views: …

More Releases from Ceramic Polymer GmbH

Ceramic Polymer: NORSOK M-501 - The Coatings for Offshore Requirements

New Product Line for demanding Offshore Areas

Regarding suitability of protective coatings for the offshore industry, the system classification

NORSOK M-501 is the most important standard for the assessment of product reliability.

The specific coatings feature extreme mechanical resistances and provide long-lasting corrosion protection

at durable sea water and weather exposure also within the tidal and splash zone.

NORSOK M-501, Edition 6 - System 1 and System 7B

Ceramic Polymer provides high-quality 2…

Ceramic Polymer: 15 Dump trailers coated with PROGUARD CN-1M – durable protect …

Up to now, the high-performance coating PROGUARD CN-1M was used for 15 special dump trailers from OptiTwin GmbH, manufacturer of utility vehicle for agriculture industry. The highly resistant internal coating was applied by the experiences partner, Reinken Company for blasting and coating technology located in Garrel/Germany. PROGUARD CN-1M provides long-term protection for the aluminum substrates against enfluences of liquid manure and solid animal residues.

The specific dump truck ”OptiTwin“…

Ceramic Polymer: Coating of copper block heat exchanger by flood method with low …

The company “Zacosin® the surface experts”, located in Gladbeck/Germany, is specified on surface protection of different devices and plant components as well as the wide scope of thermal process technology. For several years, the product PROGUARD CN-1M is applied for new coating or repair of coolers and water chambers made of copper, steel or cast aluminum. Furthermore, the system is used as sealing of thermal coated, enameled heat exchanger.

The…

More Releases for SRB

Library Automation Software Market Professional Report 2022-2029: SRB Education …

Library Automation Software Market research report offers an in-depth analysis of the global Library Automation Software Market by presenting details about the latest product launches and recent innovations in the market. It also provides data about the impact on the market growth due to covid-19. The competitive landscape has also been incorporated into the market so as to understand the market's current scenarios and trends. Moreover, the report also highlights…

MOTHER-DAUGHTER HERBALISTS ANNOUNCE FORMATION OF NEW COMPANY, SRB BOTANICA

Mother-daughter duo Stephanie Rose Bird and Olivia Bird have teamed up to launch SRB Botanica, an online purveyor of herbal products designed to pamper, protect, heal and cleanse the body, mind and spirit using responsibly sourced botanicals from Africa and around the world.

The Black Woman owned company has debuted two all-natural, all-healing products. Arnica Salve(ation) Pain Relief Formula features a proprietary blend of organic African shea butter and other oils…

Electric Rope Shovel Market Share 2018-2024| Caterpillar, Komatsu Mining Corp., …

KD Market Insights offers a latest published report on Electric Rope Shovel Market which is expected to grow at a CAGR (Compound Annual Growth Rate) of 5.1% between 2019–2024. In terms of value, the market that is worth the $771.4 Million in 2018 and is anticipated to be worth the $ 1,046.9 Million by 2024. In addition to this, global electric rope shovel market value is projected to witness a…

Global Tritium Light Sources Market 2017 - EVENLITE INC, TAWATEC, Trigalights, M …

The report focuses on global major leading industry players with information such as company profiles, product picture and specifications, sales, market share and contact information. What’s more, the Tritium Light Sources industry development trends and marketing channels are analyzed.

This report studies Tritium Light Sources in Global market, especially in North America, China, Europe, Southeast Asia, Japan and India, with production, revenue, consumption, import and export in these regions, from 2012…

Ceramic Polymer Offshore-Coatings: Protection of riser pipes for oil platforms!

China, Beibu Gulf: Various riser pipes and several water injection pipelines for oil platforms were coated externally with the protection system CERAMIC-POLYMER SF/LF-SRB. The outstanding physical properties - particularly the excellent sea water resistance - were essential for the choice of this coating product.

Project No. 1: External coating of numerous riser pipes, 5 jackets -

for connected wellhead platforms WZ 12-2 and WZ 11-4, Beibu Gulf, China

Several riser pipes for…

Ceramic Polymer: Patented prevention of pitting corrosion - coating against anae …

Developed and patented by Ceramic Polymer GmbH! (Patent No. EP 2448415 B1)

The multiannual research project of the Ceramic Polymer GmbH has been successfully completed. As the single manufacturer they feature durable protection against pitting corrosion for biogas plants and storage tanks for crude oil and all kinds of hydrocarbons.

Title of the patent: Composition for the prevention/reduction of microbe-induced biocorrosion caused by sulfate-reducing bacteria (SRB) and other microorganisms

MIC – Microbiologically influenced…