Press release

Implementing a CMMS during plant construction

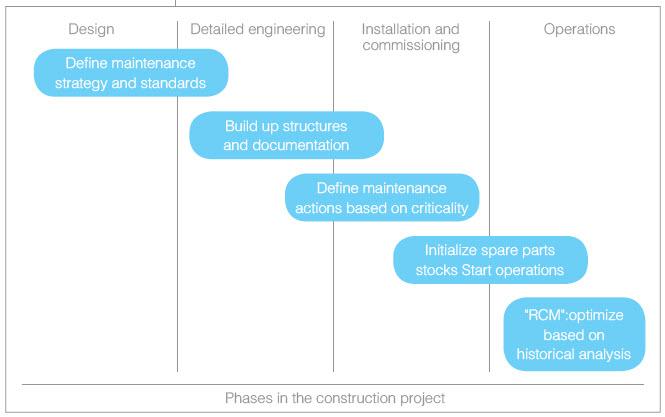

1. IntroductionExperience has shown that the earlier reliability and maintainability are taken into account in a construction project, the better. These should be specifically addressed from the design stage of a project.

This approach, which consists in paying more attention to maintenance earlier in the project, to reduce future operation cost, differs markedly from that of most Asian engineering and construction companies, which emphasize cost control during construction with progressive adjustments and modifications of the design as the project moves ahead. Too often EPC companies still lack an overall lifecycle perspective, hence the difficulty to obtain as-built drawings or preventive maintenance recommendation from them.

While the resulting speed and cost advantage has proven critical to support those countries' fast development, this construction-driven approach has also led to problems - most notably in terms of safety (accidents at construction sites) and maintenance (early replacement of major equipment, spiraling cost and reliability problems after a few years of operation). Partly as a result of this lack of preparation, maintenance is often purely reactive (firefighting) in the operation phase.

As a direct consequence of this lack of early concern for maintenance during construction, we observe that the quickest reliability improvements obtained during Siveco China project in the region are those related to design or installation problems, which should have been identified during commissioning, but instead go undetected for years. Quick fixes are applied, problems go unreported and no analysis is ever carried out. By conducting systematic root cause analysis, we are able to identify the problems and trace them back to construction issues.

2. The Siveco China approach

Based on a long experience of greenfield projects all over the world, primarily with process plants (chemical plants, power and water utilities, paper mills) and lessons learnt in China in the past 10 years, Siveco China has developed a specific expertise working with plant owners and/or their EPC companies and equipment suppliers during the construction phase, ensuring smooth transfer of technical documentation from construction to operation, supporting plant commissioning and start-up with an accurate technical database and enforcing good maintenance practice from day one.

In Asia more than anywhere else, the CMMS turns out to be the ideal tool to bring structure to what would otherwise be perceived as a very abstract concept ("Prepare for maintenance? But the equipment has not yet been delivered!"). A concrete (deliverable) system, the CMMS allows us to clearly define steps in the maintenance preparation project. The "high-tech factor" introduced by the CMMS is of course a key motivator for engineers involved in the project.

3. Main benefits

- Detailed, accurate and easily accessible plant documentation

By working directly with suppliers, detailed and accurate technical documentation (specifications, contracts, spare-parts lists, etc.) can be made available to operation engineers in a structured manner directly in the CMMS, instead of being stored in containers, in shelves or even missing. This has a direct and immediate impact on the accuracy and efficiency of the work as well as on day-to-day decisions (where to purchase a part, how to disconnect an equipment etc.).

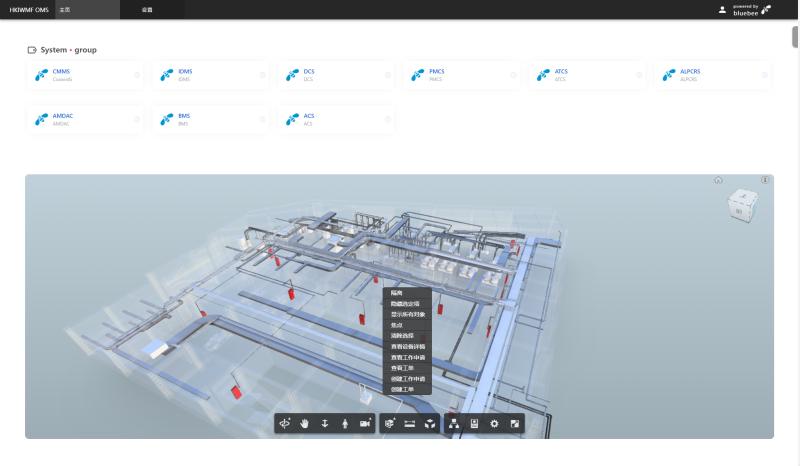

- Integration with automation systems

The construction phase is obviously the best time to integrate the CMMS with automation and supervision systems (DCS, SCADA, PLC etc.) that contain essential data for maintenance planning, as both systems can be designed and build accordingly. Large cost savings can be expected compared to similar integration performed in operation (with an existing supervision system).

More importantly, more advanced functionality can be obtained, such as a full HMI integration (operators can access technical documentation directly from their supervision HMI) and more meaningful data transfer (e.g. traditional interfaces will transfer alarms and measurements to the CMMS indiscriminately, while in a joint implementation, the process will be designed to match the maintenance strategy).

Siveco China boasts a long history of cooperation with leading automation vendors in various industries (ABB, Alstom, Siemens, Schneider, Emerson, GE etc.).

- Optimized plant lifecycle

For large process plants, this approach could easily save millions of dollars in indirect or consequential losses: downtime, increased repair costs, recurring problems etc. By taking maintenance into account early, it takes less time to get into the "useful lifetime" part of the famous reliability "bath-tub" curve (below), while the "wearing out" part will be delayed.

Siveco China Head Office

Unit J, 20th floor, Zao Fong Universe Building

No.1800 Zhong Shan Road (W)

Shanghai 200235 - PR China

About Siveco China

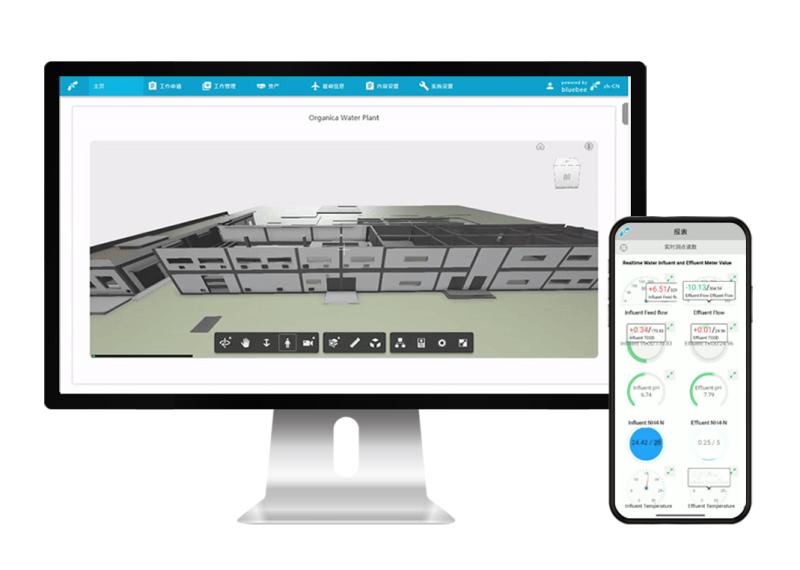

Siveco China (www.sivecochina.com), founded in 2004, is a pioneer in the development of Smart Technologies for the Operation & Maintenance of infrastructures and industrial plants, with a focus on mobile solutions "for the worker of tomorrow".

Long before the terms "smart" and "4.0" were coined, Siveco has been helping clients optimize the lifecycle of their assets and ensure regulatory compliance using IT. Based on a long experience of "maintenance with Chinese characteristics", the company has designed a unique approach combining expert maintenance consulting and technological innovation. Smart O&M solutions developed in Siveco's R&D center in Shanghai cover Asset Management, Maintenance 4.0, Risk Prevention and HSE, utilizing Mobility, IoT, BIM, AR and AI technologies.

Siveco China has over 900 customer sites all over Greater China and on the Belt & Road, including ABB, Baosteel Metal, Beijing Environment, Capital Water, Carrefour China, CEPSA, CNEEC, CNOOC, COSCO, Fushun Mining, Engie, Everbright, GE, New World Development, Saint-Gobain, Shell, Suez NWS, Yingde Gases, Zhongshan Water etc. The company boasts a growing export business, working alongside Asian EPC companies and with international clients in Southeast Asia, the Middle-East and Africa.

Siveco China has won numerous awards, most recently the prestigious Brilliant 40 Years prize by the China Electric Power Equipment Management Association, Top Ten Enterprise for Asset Informatization Service by the and the China Association of Machinery Equipment Maintenance and Renovation (CAMER) and Best Industrial Software 2017 by Control Engineering China. Previous awards include CHaINA Supply Chain Excellence Award 2013 and Engineers' Choice Awards by Plant360 in three categories in 2015.

Siveco is ISO 9001-certified by Bureau Veritas for its entire scope of business. The company is headquartered in Shanghai, where it also operates its R&D center, and has offices in Hong Kong. Siveco China is a subsidiary of Siveco Group, a European pioneer in computerized maintenance management systems (CMMS).

Siveco China publishes the "Smart Operation & Maintenance - for the worker of tomorrow" newsletter dedicated to maintenance management, bilingual English and Chinese, available to subscribers and online.

Contact

Tel (China mainland): 4006 300 213

Tel (overseas): +86 21 64403226

E-mail : info@sivecochina.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Implementing a CMMS during plant construction here

News-ID: 2675973 • Views: …

More Releases from Siveco China

ESG & decarbonization in operations: the digital gap

(This article was previously published in the December 2022 issue of APUEA magazine.)

ESG (Environmental, Social, and Governance) is a framework that helps stakeholders understand how a company is managing risks and opportunities related to environmental, social, and governance criteria. Looking at ESG from a plant management's perspective: Environmental includes energy, water and waste. Social covers safety, first and foremost. Governance consists in complying with regulations and best practices, as well…

The Future of Operation & Maintenance

Media hype has led us to believe that technology would soon revolutionize maintenance. Dreams of flying robots, video game-like smart glasses, flashing digital twins, often hold the sad promise of getting rid of maintenance people altogether. The reality remains that the more automated, the more sophisticated the systems, the more demands are put on maintenance people and their skills. The problem is compounded when this glorious technology did not address…

On the Belt & Road with clients and partners in Thailand

Thailand is a priority for Siveco China's development in Southeast Asia owing to the country's well-developed industry and growing infrastructure development. During October, our Managing Director visited local clients and partners.

Please enjoy our postcards from Thailand!

Several new partnerships and projects were also launched during this period - more on this later!

Siveco China is active all over Asia with projects not only in Thailand, but also in Brunei, India, Indonesia,…

Feedback on "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thail …

Siveco China organized a team of high-profile speakers at MIRA SUBCON EEC, Thailand's Leading Industrial Solutions Event, held on August 26 in Pattaya. The session was hosted by the Asia Pacific Urban Energy Association (APUEA). Under the theme "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thailand 4.0", the workshop aimed at sharing practical experience for the local market.

After an introduction by APUEA's Executive Director Peter Lundberg, the event…

More Releases for CMMS

SuperCMMS launches free CMMS for SME's.

BOSTON - Sept. 25, 2024 - SuperCMMS is excited to announce the launch of its innovative Computerized Maintenance Management System (CMMS), designed to simplify maintenance management for businesses across various industries. With a user-friendly interface and completely free access, SuperCMMS empowers organizations to efficiently manage work orders, streamline operations, and enhance productivity without the burden of software costs. SuperCMMS caters to a diverse range of sectors, including manufacturing, retail, fleet…

Global Equipment Maintenance Systems Market Optimizing Asset Performance and Rel …

Infinity Business Insights shared report on "Equipment Maintenance Systems Market" which provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. This report will help the viewer in Better Decision Making.

The Market for Equipment Maintenance Systems is anticipated to increase at a CAGR of 8.5% between 2022 and 2030, reaching a value of USD 30.7 billion by that time. This rise…

Computerized Maintenance Management System (CMMS) Market Industry Analysis And S …

New York, According to a new market research report published by Global Insight Services Computerized Maintenance Management System (CMMS) Market is expected to reach US$ XX bn by 2031. Report includes in-depth segmentation and market size data by categories, product types, applications, and geographies. Report also includes comprehensive analysis of key issues, trends and drivers, restraints and challenges, competitive landscape, as well as recent events such as M&A activities in…

Computerized Maintenance Management System (CMMS) Software in Healthcare Market …

Computerized Maintenance Management System (CMMS) Software in Healthcare Market Size, Status and Forecast 2019-2024 Report present the worldwide analysis with in depth study of Top players, region, type and application and its future scope.

The report mainly studies the size, recent trends and development status of the Computerized Maintenance Management System (CMMS) Software in Healthcare market, as well as investment opportunities, government policy, market dynamics (drivers, restraints, opportunities), supply chain and…

Work Order Management Tools Market Emerging Trends || Leading Players are eMaint …

A detailed research study on the Work Order Management Tools Market was recently published by DataIntelo. The report puts together a concise analysis of the growth factors influencing the current business scenario across various regions. Significant information pertaining to the industry analysis size, share, application, and statistics are summed in the report in order to present an ensemble prediction. Additionally, this report encompasses an accurate competitive analysis of major market…

Increase Employee Retention with CMMS Software

A growing number of organizations use CMMS software to streamline maintenance tasks and extend the life of equipment. Some of the more easily quantifiable benefits that CMMS software brings to an organization include higher production volumes, increased staff productivity, and lower maintenance costs. However, maintenance software also offers numerous “soft” benefits, one of which is boosting employee retention.

Employees are one of an organization’s most valuable assets, which is why…