Press release

Long-lasting protection against corrosion and abrasion – our high-performance coating Proguard CN 200

IFA Industrielle Wiegetechnik GmbH is a worldwide experienced company for special plant engineering. Their extensive field of application includes systems for weighing, mixing and dosing as well as specific production facilities and particular tank and filling installations. Through permanent advancement and relevant technical knowledge even special customer requirements can be achieved.For a global operating manufacturer of glass wool, the IFA GmbH constructed specific tanks for the wash water system.

Our product Proguard CN 200 was selected for the internal coating of the wash water tanks. The company K. H. Strohbeck GmbH & Co. KG is specialized on comprehensive activities in the range of corrosion protection and conducted all blasting and coating applications professionally. 40 years of practical experiences qualify Strohbeck GmbH & Co. KG to be a competent partner for blasting, coating and restoration of various constructions as well as huge storage tanks.

In our joint project, 9 different tanks for wash water were coated with Proguard CN 200:

• 3 Vacuum vessels, each 3,5 m³

• 1 Oven tank, 5 m³

• 1 Shaker screen tank, 40 m³

• 1 Tank for filtered wash water, 80 m³

• 1 Wash water buffer tank, 100 m³

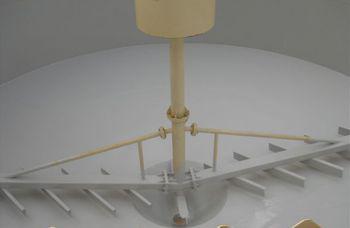

• 2 Settling tanks with stirring devices, each 160 m³

The application was carried out in one single pass

- 1 layer of 600 µm –

by airless spraying method!

Wash water is used within the production process for cooling and flushing of all plant components. It also contributes to a reduction of emissions. Moreover, wash water is taken for the cleaning of forming parts. The water is thereby contaminated with residues of binding material and glass fibers.

The recycling of the process water is effected by special screens and suction mechanisms. The residual solids settle in the bottom area of the tank and are pressed into the drainage by circulation of the stirring unit. Subsequently, the sludge is being prepared for waste disposal.

During the production process, the settling tank is constantly filled. Residual materials settle, the cleaned water drains through the overflow weir and is being channeled to further storage tanks. From there, the filtered water is taken again for the fabrication procedure.

Due to the re-use of the wash water, 80% reduction of water consumption is achieved.

Why is Proguard CN 200 the ideal choice for durable value preservation of the complex tank facilities?

High requirements regarding corrosion protection are placed in this use case. The internal walls of the various wash water tanks are exposed to an exceeding surface wear by the contained solids and glass fibers. Precisely in the bottom area of the settling tanks extreme abrasions are caused through movement of stirring devices. Only a high-performance coating can prevent permanently from wear marks and corrosion damages.

Our premium coating product Proguard CN 200 provides excellent chemical resistance,

can safely being used for drinking water applications and

protects substantially against mechanical abrasions.

The Ceramic Polymer GmbH produces high-performance coatings with integrated micro ceramic particles for different fields of application. The properties of the ceramic – chemical resistance, abrasion resistance and weathering stability – justify the high quality of our coating systems. By extra integration of microscopic special particles, we generate coating products which provide the highest protection properties.

Ceramic Polymer GmbH

Mrs. Stephanie Wuensch

Daimlerring 9

DE-32289 Roedinghausen

Germany

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Long-lasting protection against corrosion and abrasion – our high-performance coating Proguard CN 200 here

News-ID: 249561 • Views: …

More Releases from Ceramic Polymer GmbH

Ceramic Polymer: NORSOK M-501 - The Coatings for Offshore Requirements

New Product Line for demanding Offshore Areas

Regarding suitability of protective coatings for the offshore industry, the system classification

NORSOK M-501 is the most important standard for the assessment of product reliability.

The specific coatings feature extreme mechanical resistances and provide long-lasting corrosion protection

at durable sea water and weather exposure also within the tidal and splash zone.

NORSOK M-501, Edition 6 - System 1 and System 7B

Ceramic Polymer provides high-quality 2…

Ceramic Polymer: 15 Dump trailers coated with PROGUARD CN-1M – durable protect …

Up to now, the high-performance coating PROGUARD CN-1M was used for 15 special dump trailers from OptiTwin GmbH, manufacturer of utility vehicle for agriculture industry. The highly resistant internal coating was applied by the experiences partner, Reinken Company for blasting and coating technology located in Garrel/Germany. PROGUARD CN-1M provides long-term protection for the aluminum substrates against enfluences of liquid manure and solid animal residues.

The specific dump truck ”OptiTwin“…

Ceramic Polymer: Coating of copper block heat exchanger by flood method with low …

The company “Zacosin® the surface experts”, located in Gladbeck/Germany, is specified on surface protection of different devices and plant components as well as the wide scope of thermal process technology. For several years, the product PROGUARD CN-1M is applied for new coating or repair of coolers and water chambers made of copper, steel or cast aluminum. Furthermore, the system is used as sealing of thermal coated, enameled heat exchanger.

The…

More Releases for Settling

Froth Settling Units (FSU) Market Know the Scope and Trends

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Froth Settling Units (FSU) Market- (By Type (Medium & Small Volume FSU, and Large Volume FSU), By Application (Oil & Gas, Mining, Environmental, and Others)), By Region, Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Froth Settling Units (FSU) Market is valued at US$ 2,249.2…

Froth Settling Units (FSU) Market Growth and Restrain Factors Analysis Report

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Froth Settling Units (FSU) Market- (By Type (Medium & Small Volume FSU, and Large Volume FSU), By Application (Oil & Gas, Mining, Environmental, and Others)), By Region, Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Froth Settling Units (FSU) Market is valued at US$ 2,249.2…

Froth Settling Units (FSU) Market Size, Share, Research Report 2025

LP information released the report titled "Global Froth Settling Units (FSU) Market Growth 2025-2031" This report provides a comprehensive analysis of the global Froth Settling Units (FSU) landscape, with a focus on key trends related to product segmentation, Froth Settling Units (FSU) top 10 manufacturers' revenue and market share, Froth Settling Units (FSU) report also provides insights into the strategies of the world's leading companies, focusing on their market share,…

Global Froth Settling Units (FSU) Market Future Trends and Scope Analysis Report

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Froth Settling Units (FSU) Market- (By Type (Medium & Small Volume FSU, and Large Volume FSU), By Application (Oil & Gas, Mining, Environmental, and Others)), By Region, Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Froth Settling Units (FSU) Market is valued at US$ 2,249.2…

Global Froth Settling Units (FSU) Market Report- Expansive Coverage on the Profi …

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Froth Settling Units (FSU) Market- (By Type (Medium & Small Volume FSU, and Large Volume FSU), By Application (Oil & Gas, Mining, Environmental, and Others)), By Region, Trends, Industry Competition Analysis, Revenue and Forecast To 2031."

According to the latest research by InsightAce Analytic, the Global Froth Settling Units (FSU) Market is valued at US$ 2,249.2…

Froth Settling Units (FSU) Market 2024: Trends, Growth Insights, and Leading Pla …

Froth Settling Units (FSU) Market is valued at US$ 2,249.2 Mn in 2023, and it is expected to reach US$ 6,358.0 Mn by 2031, with a CAGR of 14.10% during the forecast period of 2024-2031.

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the " [https://www.insightaceanalytic.com/report/froth-settling-units-fsu-market/2633]- (By Type (Medium & Small Volume FSU, and Large Volume FSU), By Application (Oil & Gas, Mining, Environmental, and Others)),…