Press release

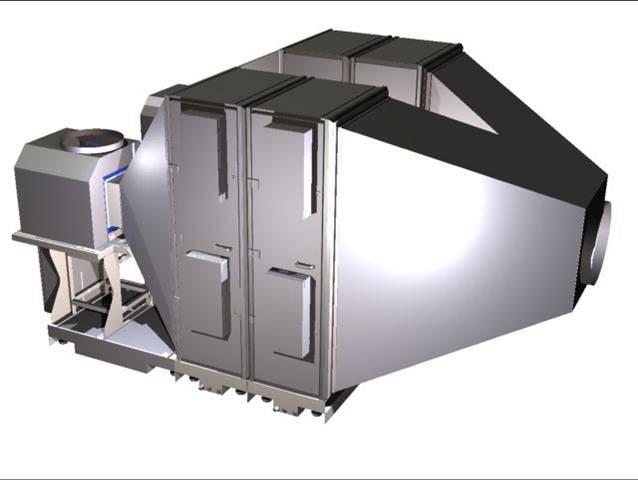

AC 6000 CIP – compact, automatically cleaning, long life

The AC 6000-CIP is an automatically cleanable air filter of compact design. Due to its special design, the air filter AC 6000-CIP is perfectly suited for direct machine integration. The aerosol-containing exhaust air flows through a double-stage electrostatic air filter. During this process, the particles (aerosols) contained in the air are charged, diverted by an electrical field between the collector plates and precipitated. The voltage applied to the collector and ioniser can be changed enabling adaptation to the specific application (e.g. oil or emulsion etc.). The AC 6000-CIP is exclusively fitted with regenerative filter elements. Thanks to the use of these elements in combination with an automatic flushing device, the filters may be cleaned as often as required which eliminates the high disposal and purchase costs for replacement filters. In excess of this, a consistently high filtration efficiency of >99% as well as permanent operational safety are granted.In regular filter operation, cooling lubricant is delivered from the customer's central system into the intermediate tank of the filter before being heated. The cleaning of the filter may be scheduled or a machine signal may be output to the filter to start the cleaning process, e.g. during downtimes or when changing the machine setup. In order to reduce oil loss, the shut-off valve to the blower is closed during the cleaning process. Using a high-pressure pump, the filter elements are cleaned via special flushing nozzles. Contaminations are removed due to the heated medium or washed off by the flushing pressure. After the end of the cleaning cycle, the contaminated flushing medium flows back into the central system. In this way, fresh cooling lubricant may be discharged from the central system as flushing medium during the next flushing cycle. The cleaning process is programmed and controlled by a PLC. For this reason, the automatic cleaning procedure may individually be adjusted to the customer's requirements.

*The filtration efficiency of >99% refers to a particle size of smaller 1µm. The values were measured and confirmed by the independent institute ILK Dresden.

LTA Lufttechnik is a renowned partner for complete solutions in air technology. The company projects, produces and delivers air filter and fire protection systems for trade and industry. For over 30 years, LTA has been researching, developing and manufacturing aerosol separation products. The electrostatic separation method is eco-friendly and has continuously been further developed and improved.

LTA Lufttechnik GmbH

Junkerstraße 2

D - 77787 Nordrach

Tel.: +49/7838/84-245

Fax: +49/7838/84-308

Email: info@lta.de

Homepage: www.lta.de

press contact:

Mr. Philipp Fehrenbach

sales office-duty and marketing-manager

Tel.: +49/7838/84-331 (Fax: -308)

Email: philipp.fehrenbach@lta.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release AC 6000 CIP – compact, automatically cleaning, long life here

News-ID: 236829 • Views: …

More Releases from LTA Lufttechnik GmbH

Industrial Environmental Protection Through Energy Efficiency

In industrial applications, environmental protection often has to give way to commercial interests although both interests may be connected by means of targeted improvements in the fields of energy efficiency. This definitely makes sense not just for technical reasons but also since the number of norms and standards is rocketing upwards.

LTA pursues two strategies pertaining to the suction of machine tools in close cooperation with the machine and plant manufacturers.

For…

Bulk order received from Opel Szentgotthard, Hungary

LTA Industrial Air Cleaning has received a bulk order from Opel Szentgotthard (Hungary), for delivery of suction systems for two crankshaft-lines, three block- and two cylinder head lines in the engine production. While doing this the scope of supply from LTA contains the building of the total devices from the projecting, delivery, building site management, installation, start-up, training and measurements of the suction devices. The project comprises 11 high-duty filters…

Energy-Conserving Suction of Aerosols & Smoke at a Dörries Scharmann Machining …

The Alstom Power Service company in Berlin is active in service, maintenance & repair of turbines for power generation. At a Dörries Scharmann machining center, a lot of emulsion mist and smoke escaping through the not 100% capsuled machine cover is produced during the turning/milling processes due to the large size of the parts. It was LTA's task to prevent just that. An LTA air filter type AC 3061 was…

Suction of Release Agents of Hot Forming Presses

Description of project & system:

On the 1st expansion level, an LTA air filter type AC 8002 with a suction output of approx. 10,000 m³ sucks the release agent vapors of 3 presses The aerosols are separated from the contaminated air and stick to the collector surface or condense partially and are drained towards the bottom. Once per day, the offline cleaning cycle is started. For this purpose, the system is…

More Releases for Air

Thermoelectric Assemblies Market, By Type (Air to Air, Direct to Air, Liquid to …

The thermoelectric assemblies market is expected to witness market growth at a rate of 8.25% in the forecast period of 2021 to 2028. Data Bridge Market Research report on thermoelectric assemblies market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market's growth. The rise in the application of thermoelectric assemblies in the food and beverage industry…

Air Ambulance Market 2019 Global Analysis By Key Players – EMA Global , Native …

WiseGuyReports.Com Publish a New Market Research Report On –“ Air Ambulance Market 2019 Global Analysis By Key Players – EMA Global , Native American Air Ambulance, Air Medical Group, REVA Air Ambulance, PHI Air Medical ”.

Air Ambulance Industry 2019

Description:-

Air Ambulance is also known as helicopter emergency medical service, it refers to the aircraft specially adapted for carrying patients with critical condition and serious injury after permanent professional medical…

Air Ambulance Services Market 2019 AMR PHI Air Medical Scandinavian Air Ambulanc …

Air medical services is a comprehensive term covering the use of air transportation, airplane or helicopter, to move patients to and from healthcare facilities and accident scenes. Personnel provide comprehensive prehospital and emergency and critical care to all types of patients during aeromedical evacuation or rescue operations aboard helicopter and propeller aircraft or jet aircraft.

Request a Sample of this Report @ http://www.orbisresearch.com/contacts/request-sample/2398576 …

Air Ambulance Services Market 2026: Air Methods Corporation, Deccan Charters, Sc …

Coherent Market Insights has announced the addition of the “Air Ambulance Services Market Size Status and Forecast 2026”, The report classifies the global Air Ambulance Services Market in a precise manner to offer detailed insights about the aspects responsible for augmenting as well as restraining market growth.

Publisher’s Air Ambulance Services market research report provides the newest industry data and industry future trends, allowing you to identify the products and…

Air Ambulance Services Market Growth, & Key Business Strategies by Leading Indus …

Coherent Market Insights has announced the addition of the “Air Ambulance Services Market Size Status and Forecast 2026”, The report classifies the global Air Ambulance Services Market in a precise manner to offer detailed insights about the aspects responsible for augmenting as well as restraining market growth.

This report studies the global Air Ambulance Services Speaker market, analyzes and researches the Air Ambulance Services Speaker development status and forecast in…

Air Ambulance Services Market Analysis Report, Regional Outlook with Key Players …

Coherent Market Insights has announced the addition of the “Air Ambulance Services Market Size Status and Forecast 2026”, The report classifies the global Air Ambulance Services Market in a precise manner to offer detailed insights about the aspects responsible for augmenting as well as restraining market growth.

This report studies the global Air Ambulance ServicesSpeaker market, analyzes and researches the Air Ambulance Services Speaker development status and forecast in North…