Press release

Avoiding pitfalls when implementing WCM / TPM in China

Companies trying to implement World Class Manufacturing (WCM) or Total Productive Maintenance (TPM) or Lean Manufacturing in China, usually as a part of a corporate roll-out, face specific challenges, which may differ from those observed in Japan or in the West.Maintenance jobs performed by operators, known as "autonomous maintenance", and more generally the involvement of production staff in the improvement process are one of the key principles of TPM. One of the benefits of a successful TPM program would be to help operators acquire more responsibility, starting with simple jobs such as daily cleaning rounds, lubrication, bolts tightening and various checks. To those daily care routines, other activities are later added, such as the proactive tagging, directly on the equipment, of problems detected by operators during inspections – an excellent tool to visualize poor maintenance and its consequences. The final step consists in involving production teams in analysis and improvement sessions, from which the actual benefits of TPM will derive.

This article will look at some of the Chinese specificities that influence the TPM process, as observed in many projects conducted by Siveco, so as to help industrial managers avoid some the pitfalls.

Understanding HR limitations

The key words for autonomous maintenance may be: involvement, responsibility, and pro-activity – all which may be considered at odds with the HR situation in most companies… The challenge of trying to change old habits is obvious, although not unique to China. Specific obstacles exist, however, that make it more difficult for production workers to play their role in the TPM process, i.e. to share their experience and know-how of the machines. More often than not, in China, workers are not experienced enough: while they may have the theoretical knowledge in a specific discipline, the high turnover rate and lack of multidisciplinary skills makes it more difficult to gain mastery in their equipment.

Although there is no instant solution to this problem, we could state the obvious: plans should be put in place to reduce turnover and improve the skill level. Siveco's approach, based on taking the company through all the steps of an ISO 55000-compliant maintenance improvement plan, with support from Smart technologies, will greatly contribute to this. The technological solution itself, in particular the mobile solution for technician, acts as a powerful motivation tool for line workers, who seldom benefits from technologies deployed in the plant. In any case, these specific HR constraints should be kept in mind when rolling out a TPM program.

Reducing breakdown rate before TPM

Before launching autonomous maintenance activities, it is necessary to have the failure rate of the machines under control, and if possible relatively low. How to transfer first line maintenance responsibility to operators if the equipment is always breaking down? We often see maintenance technicians working full-time on emergency maintenance, always on the shop floor fixing machines: in such a situation, autonomous maintenance cannot be implemented (apart from cleaning and basic checks).

Instead, it may be preferable to stick with the traditional organization and to focus on reducing the failure rate through preventive maintenance. This is evidently true for aging facilities, making TPM naturally more applicable to new factories.

Implementing work feedback first

When transferring part of the maintenance job to production, the previous uniqueness of "memory" is lost: the maintenance department was once the unique depositor of all the plant knowledge, but now this knowledge is spread across the organization. Having a system in place to centralize the knowledge, based on work feedback, is critical. Without such a system, there is a significant risk that production and maintenance do not know what the other is doing. On one hand, a comprehensive maintenance record is a necessary tool for failure analysis (more on that in the next section). On the other hand, a work feedback system will allow, for example, maintenance technicians to know that a quick fix was applied by production operators, in all good faith, which may require further attention.

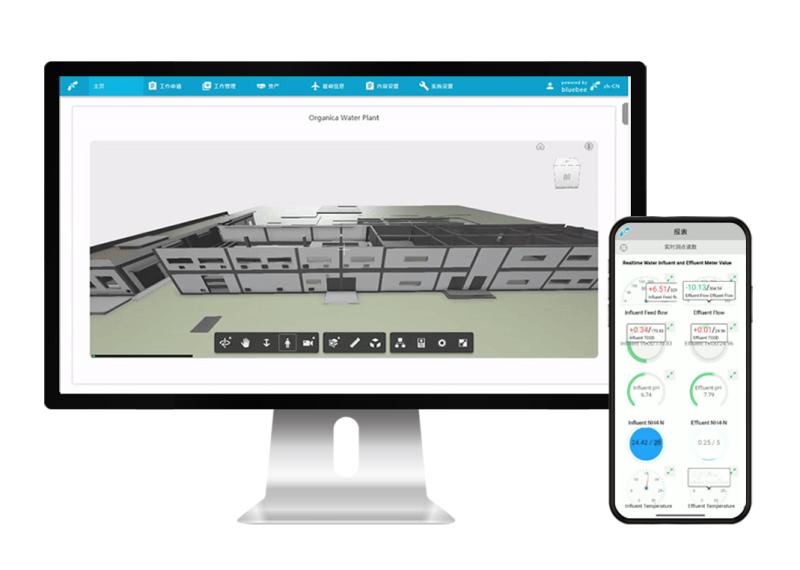

We recommend focusing on Work Order (sometimes also called Job Request) to capture the most essential information. This process can be greatly simplified using predefined check-lists: symptom, failure type, downtime (exact values may not even be needed, e.g. operators could choose between 5min, 30min, 2h, 4h, 8h+). Using Siveco's mobile solution bluebee® "for the worker of tomorrow" this process becomes painless: employees are equipped with smartphones, take pictures of the problem, select the information needed and can receive troubleshooting help directly from a central database.

The most striking benefits from any maintenance management program, including TPM, will derive from the systematic analysis of historical records. Experience has proven that this can only be achieved with a CMMS: paper and Excel-based systems simply do not allow proper technical analysis over a period longer than a few weeks. Real measurable benefit will come from improvement decisions based on historical data.

Enabling maintenance improvement

Plant improvement can only be carried out if the maintenance team, freed of part of their workload (first-line maintenance now transferred to operators) is able to dedicate their efforts to it. When technicians were busy repairing the machines, this process could not take place. On the other hand, if technicians used to be lazying around in the workshop, TPM may not have been the right choice.

It is essential for maintenance workers to understand that they should now involve in, and be measured on, reliability improvement. This is not like in the old days, when they could sleep in the workshop waiting for the next breakdown.

The maintenance team has to be prepared for this change. More particularly, it should acquire some of the key methodologies and tools needed to perform their new work: root cause analysis, the design and implementation of preventive maintenance, etc. The basic reports and KPIs have to be in place.

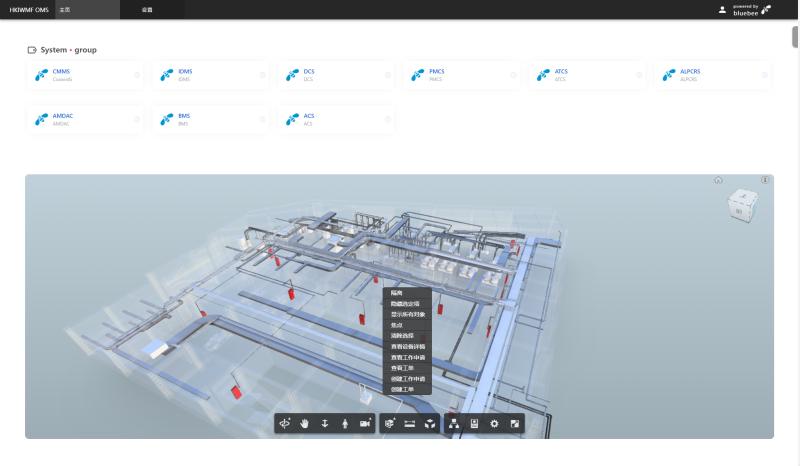

TPM or WCM reports are however notoriously difficult to obtain from traditional IT or ERP systems, as they involve complex data from multiple sources. One of our large automotive clients for example could never extract such report from their multi-million dollar integrated ERP system, in spite of many efforts trying to develop such reports. With Siveco's Smart Maintenance solution, the WCM reports are immediately available for analysis and decision support:

In conclusion – a prerequisite to TPM

In conclusion, TPM can be implemented only when:

The failure rate is stable and preferably low. If not, this should be the first priority and Siveco can help.

A work order system is in place, which Siveco's bluebee® mobile solution can able while acting as a strong motivator.

Reporting and analytics capability is in place, again with technology as enabler and motivator.

The maintenance team is prepared to take up a new role dedicated to improvement, with support from top management.

While TPM has proven very successful in countries with a long industrial history, where maintenance engineers already had a strong methodological background, China brings its own specific challenges. It is our experience that a TPM initiative cannot succeed without those fundamentals – structure, methodologies and tools. As per Siveco's experience, implementing a Smart Maintenance solution has proven to be the most efficient approach to create such a structure, in a sustainable manner, in China. This implementation will have to be done before or at the same time as TPM is introduced to the company.

In next article, we will share how a Siveco automotive industry client used our Coswin 8i solution to support the "5 Whys + 1 How" methodology mandated by their WCM process. The articles takes you through all the steps of using Coswin 8i's highly flexible user interface to realize this need.

Siveco China Head Office

Unit J, 20th floor, Zao Fong Universe Building

No.1800 Zhong Shan Road (W)

Shanghai 200235 - PR China

About Siveco China

Siveco China (www.sivecochina.com), founded in 2004, is a pioneer in the development of Smart Technologies for the Operation & Maintenance of infrastructures and industrial plants, with a focus on mobile solutions "for the worker of tomorrow".

Long before the terms "smart" and "4.0" were coined, Siveco has been helping clients optimize the lifecycle of their assets and ensure regulatory compliance using IT. Based on a long experience of "maintenance with Chinese characteristics", the company has designed a unique approach combining expert maintenance consulting and technological innovation. Smart O&M solutions developed in Siveco's R&D center in Shanghai cover Asset Management, Maintenance 4.0, Risk Prevention and HSE, utilizing Mobility, IoT, BIM, AR and AI technologies.

Siveco China has over 900 customer sites all over Greater China and on the Belt & Road, including ABB, Baosteel Metal, Beijing Environment, Capital Water, Carrefour China, CEPSA, CNEEC, CNOOC, COSCO, Fushun Mining, Engie, Everbright, GE, New World Development, Saint-Gobain, Shell, Suez NWS, Yingde Gases, Zhongshan Water etc. The company boasts a growing export business, working alongside Asian EPC companies and with international clients in Southeast Asia, the Middle-East and Africa.

Siveco China has won numerous awards, most recently the prestigious Brilliant 40 Years prize by the China Electric Power Equipment Management Association, Top Ten Enterprise for Asset Informatization Service by the and the China Association of Machinery Equipment Maintenance and Renovation (CAMER) and Best Industrial Software 2017 by Control Engineering China. Previous awards include CHaINA Supply Chain Excellence Award 2013 and Engineers' Choice Awards by Plant360 in three categories in 2015.

Siveco is ISO 9001-certified by Bureau Veritas for its entire scope of business. The company is headquartered in Shanghai, where it also operates its R&D center, and has offices in Hong Kong. Siveco China is a subsidiary of Siveco Group, a European pioneer in computerized maintenance management systems (CMMS).

Siveco China publishes the "Smart Operation & Maintenance - for the worker of tomorrow" newsletter dedicated to maintenance management, bilingual English and Chinese, available to subscribers and online.

Contact

Tel (China mainland): 4006 300 213

Tel (overseas): +86 21 64403226

E-mail : info@sivecochina.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Avoiding pitfalls when implementing WCM / TPM in China here

News-ID: 2286339 • Views: …

More Releases from Siveco China

ESG & decarbonization in operations: the digital gap

(This article was previously published in the December 2022 issue of APUEA magazine.)

ESG (Environmental, Social, and Governance) is a framework that helps stakeholders understand how a company is managing risks and opportunities related to environmental, social, and governance criteria. Looking at ESG from a plant management's perspective: Environmental includes energy, water and waste. Social covers safety, first and foremost. Governance consists in complying with regulations and best practices, as well…

The Future of Operation & Maintenance

Media hype has led us to believe that technology would soon revolutionize maintenance. Dreams of flying robots, video game-like smart glasses, flashing digital twins, often hold the sad promise of getting rid of maintenance people altogether. The reality remains that the more automated, the more sophisticated the systems, the more demands are put on maintenance people and their skills. The problem is compounded when this glorious technology did not address…

On the Belt & Road with clients and partners in Thailand

Thailand is a priority for Siveco China's development in Southeast Asia owing to the country's well-developed industry and growing infrastructure development. During October, our Managing Director visited local clients and partners.

Please enjoy our postcards from Thailand!

Several new partnerships and projects were also launched during this period - more on this later!

Siveco China is active all over Asia with projects not only in Thailand, but also in Brunei, India, Indonesia,…

Feedback on "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thail …

Siveco China organized a team of high-profile speakers at MIRA SUBCON EEC, Thailand's Leading Industrial Solutions Event, held on August 26 in Pattaya. The session was hosted by the Asia Pacific Urban Energy Association (APUEA). Under the theme "Accelerate Optimizing your Asset Lifecycle: Best Practices in Thailand 4.0", the workshop aimed at sharing practical experience for the local market.

After an introduction by APUEA's Executive Director Peter Lundberg, the event…

More Releases for TPM

TPM-60H Head/Pipe Chamfering Machine Large Pipe Chamfering Case Study

In the realm of industrial manufacturing, the pressure vessel head pipe dual-purpose beveling machine stands out as a vital tool for enhancing efficiency and precision in metalworking processes. This innovative machine is designed to perform beveling operations on both pressure vessel heads and pipes, making it an indispensable asset in various sectors, including oil and gas, chemical processing, and shipbuilding.

A certain Heavy Industry Group Co., Ltd. was established in 2016,…

Trade Promotion Management (TPM) Market Is Booming So Rapidly SAP, Oracle, Wipro

HTF MI just released the Global Trade Promotion Management (TPM) Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major companies profiled in Trade Promotion Management (TPM) Market…

Trusted Platform Module (TPM) Market Size Trends and Forecast by Application, Ty …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to Market Research Intellect, the global Trusted Platform Module (TPM) market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The Trusted Platform Module (TPM) market is experiencing steady growth driven by the increasing need for robust security solutions across industries. As cyber…

Trusted Platform Module (TPM) Market Is Booming Worldwide |Posiflex, MediaTek, C …

The latest research study released by AMA on the Trusted Platform Module (TPM) Market offers over 233+ pages of analysis on business strategies employed by key and emerging industry players. It provides insights into current market developments, landscape, technologies, drivers, opportunities, market outlook, and status. The market study is segmented by key regions driving market growth. The Trusted Platform Module (TPM) study combines qualitative and quantitative market data, primarily collected…

Trusted Platform Module (TPM) Market to Witness Growth Acceleration by 2029

Trusted Platform Module (TPM) market is projected to grow from USD 1.02 Billion in 2017 by 2029, at a Compound Annual Growth Rate (CAGR) of 10.5% during the forecast period. The growth of the TPM market is propelled by the increasing demand for secured and authenticated transactions across different industries, such as automotive, banking and finance, healthcare, retail, and others.

Important changes in the business allow key players to attain larger…

Know How Trusted Platform Module (TPM) Market is rising globally by 2029

Trusted Platform Module (TPM) Market Study 2023-2029:

Trusted Platform Module (TPM) Market (Newly published report) which covers Market Overview, Future Economic Impact, Competition by Manufacturers, Supply (Production), and Consumption Analysis, and focuses on various products and other market trends.

The market research report on the global Trusted Platform Module (TPM) industry provides a comprehensive study of the various techniques and materials used in the production of Trusted Platform Module (TPM) market products.…