Press release

The Significance of Studying the Heat-Affected Zone of Welded Pipe Welding

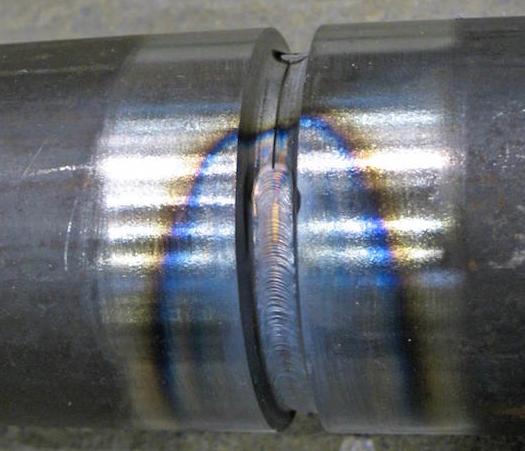

Welding heat-affected zone(HAZ) is different from welding seam. Welding seam guarantees performance requirements through chemical composition adjustment, redistribution and proper welding process, while the performance of heat-affected zone cannot be adjusted by chemical composition. This is due to the microscopic effect of thermal cycling. Due to the uneven distribution of the structure, for general welded structures, the hardening, embrittlement, toughening and softening of the heat-affected zone, as well as comprehensive mechanical properties, corrosion resistance and fatigue properties, are mainly considered, which should be determined according to the specific application requirements of the welded structure.A complete high-frequency welded pipe weld (ERW pipe) is composed of a fusion zone and a heat-affected zone. The fusion zone is a narrowly defined weld. Welding theory and practice point out that the quality of welding depends not only on the weld, but also on the heat-affected zone, sometimes heat-affected The problem of the zone is much more complicated than that of the weld, which is especially obvious when welding high-strength alloy steel pipes. Many failures of oil pipes and high-strength alloy steel pipes prove that the problem often lies in the heat-affected zone.

Therefore, studying the structure and performance changes of heat-affected billets is of great significance to the welding strength and quality of welded pipes. The structure of the heat-affected zone of low-carbon equivalent welded pipes, and the structure and morphology of the welded heat-affected zone are closely related to the carbon equivalent of steel. The welding heat-affected zone of the longitudinally welded pipe belongs to the category of low carbon equivalent, which is composed of coarse grain area, phase change recrystallization area, incomplete recrystallization area, recrystallization area and age embrittlement area.

The temperature in the superheated zone is between 1400 and 1100°C. The closer to the fusion zone, the higher the temperature, which manifests as some refractory points on the solidus line, such as carbides and oxides that melt into austenite and austenite crystals. Coarse grains, coarse austenite tends to form overheated Widmanite structure during cooling, resulting in a decrease in toughness.

The phase change recrystallization zone, the temperature is between 1100 ~ 850 °C, when heated, the recrystallization phase change occurs, so that the grains are refined, which is equivalent to the structure of low carbon steel after normalizing, and has good comprehensive mechanical properties. In the incomplete recrystallization zone, the temperature is between 850 and 700°C. Only part of the metal in this zone undergoes recrystallization phase transformation. The coarse and fine grain regions of the original ferrite coexist, and the mixed mechanical properties are poor.

In the recrystallization zone, when the temperature is between 700 and 500°C, the internal structure of the metal will not change after heating, only the shape of the crystal grains will change. It is an equiaxed ferrite crystal grain, which is stronger and harder than the base material Low, plasticity and toughness increase. It is the softening zone and the embrittlement zone of the weld. The temperature is between 500°C and room temperature. The metal structure is close to the base metal. The longer the storage time, the closer the structure and performance to the base metal. Through the analysis of the structure of the welding HAZ, not only the welding process can be improved, but also the formation and distribution of the welding stress of the welded pipe can be understood.

Tips: ERW welded pipe is formed by rolling strip and welding the seam, with tighter dimensional tolerances and less weight. The weld seam is heat treated after welding that no untempered martensite remains, and the weld flash can be removed from both inner and outer surfaces.

Permanent Steel Manufacturing Co.,Ltd have years of experience in manufacturing of carbon steel pipe, stainless steel tube, hollow section, pipe fittings.(Fluid Pipe/Boiler Tube/Fire Pipe/Line Pipe/Structure Tube) Please refer to: https://www.permanentsteel.com

LinkedIn: https://www.linkedin.com/company/permanent-steel-manufacturing-co-ltd

Permanent Steel Manufacturing Co.,Ltd: https://www.permanentsteel.com

Address: #668,Lugu Avenue,Hi-Tech Industrial Development Zone,Changsha,China

Postcode:410205

Tel:0086-731-88787784

Fax:0086-731-89878292

E-mail: info@permanentsteel.com

Whatsapp:0086-13548700205

WeChat: FQ-314

ERW steel pipe: https://www.permanentsteel.com/productshow/erw-steel-pipe.html

ERW Pipe Manufacturing Process: https://www.permanentsteel.com/newsshow/erw-pipe-manufacturing-process.html

ASTM A53 GR.B ERW: https://www.permanentsteel.com/newsshow/astm-a53-erw-pipe.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release The Significance of Studying the Heat-Affected Zone of Welded Pipe Welding here

News-ID: 2267581 • Views: …

More Releases from Permanent Steel Manufacturing Co.,Ltd

Seamless Pipes for Energy Equipment

Seamless pipes play an extremely important role in energy equipment, especially in systems that need to withstand harsh working conditions such as high temperature, high pressure, and corrosion. Since there are no welded seams in its manufacturing process, seamless steel pipe has higher structural integrity, uniform mechanical properties and excellent pressure bearing capacity, making it the preferred piping material in the energy sector. Permanent Steel Manufacturing Co., Ltd. has carefully…

Can Galvanized Steel Pipes be Painted?

Galvanized steel pipe is a common metal pipe, which is widely used in construction, water supply, HVAC and other fields due to its excellent anti-corrosion performance. However, with the diversification of usage scenarios, many people have begun to consider painting galvanized steel pipes to improve their aesthetics or further enhance their protective effect.

Basic characteristics of galvanized steel pipe

Galvanized pipes are metal pipes made by coating the surface of ordinary…

How to Remove Weld Spots from 304 Stainless Steel Pipes?

Welded pipes are made by welding, and the welds of 304 stainless steel pipes will leave more or less orange, blue, and black weld spots after welding, which are very difficult to remove. The presence of weld spots not only affects the appearance, but also accelerates corrosion in the atmosphere, reduces corrosion resistance, and has a certain impact on use. So, how to remove weld spots on 304 stainless steel…

How to Store Stainless Steel Elbows?

Stainless steel elbows are elbows made of stainless steel. The Stainless steel elbow is a kind of elbow fittings. Because of the material, they can remain rust-free and non-corrosive for a long time, so they are more reliable to use. And the service life is longer than that of iron, so many people now choose to use stainless steel elbows. Then after we buy the stainless steel elbow, its storage…

More Releases for Pipe

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Comparison of ERW Welded Pipe and Seamless Steel Pipe (tested by PetroChina Pipe …

1. Outer diameter tolerance

ERW steel pipe: It is cold-formed and sizing is completed by reducing the diameter by 0.6%. The process temperature is basically constant at room temperature. Therefore, the outer diameter is controlled accurately and the fluctuation range is small, which is helpful to eliminate black leather buckles.

Seamless steel tube: The hot-rolling forming process is used, and its sizing is completed at about 8000C. The raw material composition, cooling…

Conduit Pipe Market Bolstered by Emerging New Advancements, Says QYR | ABB, Nati …

LOS ANGELES, United States: The report is an all-inclusive research study of the global Conduit Pipe market taking into account the growth factors, recent trends, developments, opportunities, and competitive landscape. The market analysts and researchers have done extensive analysis of the global Conduit Pipe market with the help of research methodologies such as PESTLE and Porter’s Five Forces analysis. They have provided accurate and reliable market data and useful recommendations…

HDPE Pipes Market Current Trends and Detailed Study with Forecast to 2028 | Oil …

Global HDPE Pipes Market: Overview

The application of high density polyethylene (HDPE) pipes has increased in industry like chemical, electronics, and gas distribution. As a result of this extensive application, the global HDPE pipes market is witnessing a substantial growth in the forecast period of 2018 to 2028. Moreover, the growing demand for HDPE pipes in drainage and sewerage industry is another factor that is responsible for the growth of…

Global HDPE 100 Pipe Market 2017 LESSO, Cangzhou Mingzhu, Junxing Pipe, Ginde Pi …

In this report, the global HDPE 100 Pipe market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Global Market Report HDPE 100 Pipe Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This HDPE 100 Pipe Industry report also states Company Profile, sales,…

Anti-corrosion Steel Pipe and Coating Steel Pipe

Anti-corrosion steel pipe refers to do anti-corruption treatment for the ordinary steel pipe with special technology, making the steel pipe equipped certain corrosion resistance.Generally used in waterproof, anti-rust, acid and alkali proof, anti-oxidation and so on.Different needs, different inside and outside wall corresponding anti-corrosion measures.Common are: epoxy coal tar anti-corrosion, anti-corrosion epoxy coatings, urethane paint anti-corrosion, IPN8710 water pipeline corrosion protection, non-toxic paint anti corrosion,anti-corrosion polymer coating, steel pipe lining…