Press release

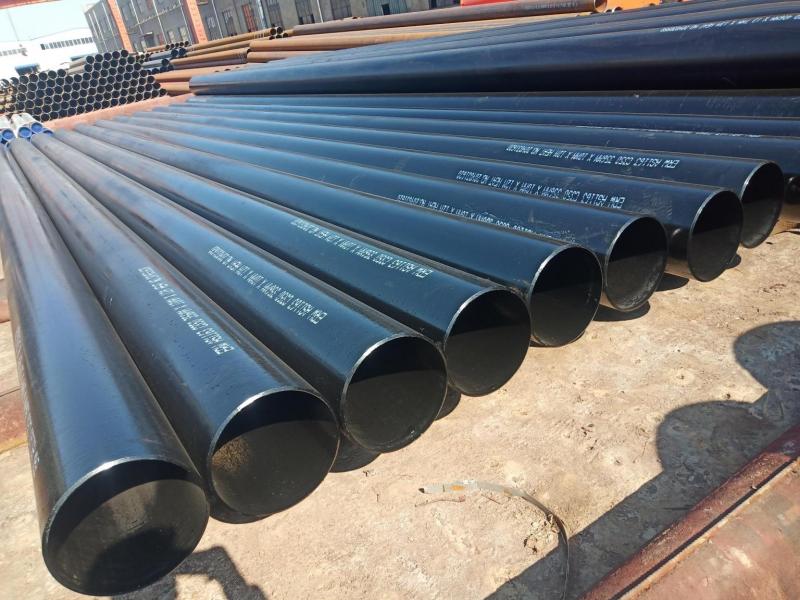

Oil and Gas Storage and Transportation Projects Promote the Use of ERW Steel Pipes

The operation conditions of oil storage and transportation system in petrochemical enterprises are relatively "mild" compared with production equipment. Its working pressure is generally below 2.5Mpa, in some cases up to 4.0 Mpa; the working temperature is generally below 100 °C, the highest does not exceed 1809C, only when purged with 1.0Mpa steam, the highest temperature up to about 250 °C. Various oil products-generally no corrosion or only slight corrosion. Production operations of oil storage and transportation, such as oil loading and unloading, reconciliation, and transportation, are generally intermittent corrosion. Production operations of oil storage and transportation, such as oil loading and unloading, reconciliation, and transportation, are generally intermittent operations. Only a few pumps that supply raw materials to production equipment are continuously operated.The selection of pipes for oil storage and transportation systems in petrochemical enterprises is currently in accordance with the industry standard "General Rules for the Selection of Pipeline Design Equipment for Petrochemical Enterprises" (SH3059-94). The specification for selection of resistance welded carbon steel straight seam steel pipe (ERW steel pipe): the product whose expansion rate does not exceed 1.5% of the outer diameter after cold expansion should be used in pipes with a design temperature not exceeding 200 °C without cooling The expanded steel pipe can be used for pipes whose design temperature does not exceed 425 °C. It can be seen from this that ERW steel pipes can be used in the oil storage and transportation system. However, in the actual design work, each design unit has more specific pipe selection regulations and some customary practices.

Due to the limitation of historical conditions, there were no ERW steel pipes in China in the 1970s and 1980s, and only high-frequency welded steel pipes that could be used for low-pressure fluids (such as water, compressed air, etc.), that is, according to the national standard "galvanized welded steel pipes for low-pressure fluid transportation" ( GB3091) and "welded steel pipes for low-pressure fluid transportation" (GB3092). There are also spiral welded steel pipes produced in accordance with industry standards "Spiral Seam Submerged Arc Welded Steel Pipe for Pressure Fluid Transport" (XSY5036) and "Spiral Seam High Frequency Welded Pipe for Pressure Fluid Transport" (XSY5038). This kind of steel pipe can generally only be used in non-toxic medium pipes with a design pressure not exceeding 1.0Mpa. Therefore, in the design of oil storage and transportation systems, no matter what the actual production and operating conditions are, only seamless steel tubes can be used. For a long time, the specific pipe selection regulations of various units have specified the use of seamless steel pipes under general circumstances. Only in DN2350 can spiral spiral submerged arc welded steel pipes be used (the main reason is that large-diameter seamless steel pipes need to be imported at the time, the price expensive). Sometimes in order to select materials for production equipment, it is also required to select seamless steel pipes in the oil storage and transportation system.

Since the 1990s, my country has successively introduced ERW steel pipe production technology and equipment from abroad, and has been able to produce DN80-300 ERW steel pipes, with an annual output of up to millions of tons. It can be produced according to API, ASTM, GB/T and other standards. Although the price of these products is much lower than that of seamless steel pipes and can also be adapted to many production occasions in petrochemical enterprises, these products have not been widely used in PetroChina and Sinopec systems due to various reasons.

For the construction of long-distance pipelines, the choice of pipe materials and pipe-making methods is extremely important. It not only affects the construction technology and quality of pipeline engineering, but also affects the safe operation and management of pipelines in the future, as well as the entire project. Investment has a huge impact (in the entire project investment of long-distance pipelines, the Investment generally accounts for about 50%-65%).

The length of the trunk line from Zhenhai Refining & Chemical Co., Ltd. to Xiaoshan Nanyang Oil Depot in Zhejiang is 153KM, and the length of the branch line is 5.3KM. The adopted pipe diameter is 355.6*6.4mm, X42 steel grade, the design working pressure is 6.4Mpa, and the conveyed medium is 90*, 93# unleaded gasoline. 0# light diesel and 3# aviation kerosene and other four oil products. The maximum transmission volume of the designed project in the first phase is 2,232,900 tons/year, while the maximum transmission capacity of the pipeline design is 3.102 million tons/year. Pipeline anticorrosion adopts anticorrosion system combining sintered epoxy powder coating and applied current cathodic protection. The welding method is manual all-position downward welding. The project uses ERW steel pipes in total 7100 tons, calculated at an average saving of 800 yuan/ton per ton (compared to SML steel pipes), the entire project will save 7100x800=568 million yuan for a single steel pipe, which has achieved gratifying economic benefits.

In the history of the world, ERW steel pipes have tended to be mature and perfect in the 1980s. A large number of domestic advanced technologies have been introduced in the 1990s, and they have been promoted. Not only in theory but also in practice, ERW steel pipes can be explained in the field of oil and gas storage and transportation. Reliability and safety of transmission quality and reduce pipeline construction investment. In the future oil and gas storage and transportation projects and pipeline construction, we must break the old habits inherited from the design and vigorously promote the use of ERW steel pipes.

Permanent Steel Manufacturing Co.,Ltd: https://www.permanentsteel.com

Address: #668,Lugu Avenue,Hi-Tech Industrial Development Zone,Changsha,China

Postcode:410205

Tel:0086-731-88787784

Fax:0086-731-89878292

E-mail: info@permanentsteel.com.com

ERW steel pipe: https://www.permanentsteel.com/productshow/erw-steel-pipe.html

Permanent Steel Manufacturing Co.,Ltd has been committed to being a major supplier of quality kinds of carbon steel pipe, stainless steel tube, hollow section, numerous types of piping equipments including Bend, Cap, Coupling, Elbow, Reducer, Stub End, Tee, Olet, Joint, Gasket, etc. As a factory,which specializing in the production, processing and sales of various steel pipes and pipe fittings size enterprises, headquartered in Hunan, the production base is located in Shandong and Tianjin. So far, the facility occupies more than 228,000 square feet under roof and includes two working mills and quality assurance chemical- and strength-testing laboratories on site and located on a 2,000-acre site with more than 60 acres under roof, is home to one of the world’s largest cupolas; and the Contiarc, the first-of-its-kind continuous arc furnace.Our company has imported the advanced productive equipment and the inspection equipment, we will do the UT testing, RT testing on line, and the Hydrostatic testing during the production.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Oil and Gas Storage and Transportation Projects Promote the Use of ERW Steel Pipes here

News-ID: 2090088 • Views: …

More Releases from Permanent Steel Manufacturing Co.,Ltd

Seamless Pipes for Energy Equipment

Seamless pipes play an extremely important role in energy equipment, especially in systems that need to withstand harsh working conditions such as high temperature, high pressure, and corrosion. Since there are no welded seams in its manufacturing process, seamless steel pipe has higher structural integrity, uniform mechanical properties and excellent pressure bearing capacity, making it the preferred piping material in the energy sector. Permanent Steel Manufacturing Co., Ltd. has carefully…

Can Galvanized Steel Pipes be Painted?

Galvanized steel pipe is a common metal pipe, which is widely used in construction, water supply, HVAC and other fields due to its excellent anti-corrosion performance. However, with the diversification of usage scenarios, many people have begun to consider painting galvanized steel pipes to improve their aesthetics or further enhance their protective effect.

Basic characteristics of galvanized steel pipe

Galvanized pipes are metal pipes made by coating the surface of ordinary…

How to Remove Weld Spots from 304 Stainless Steel Pipes?

Welded pipes are made by welding, and the welds of 304 stainless steel pipes will leave more or less orange, blue, and black weld spots after welding, which are very difficult to remove. The presence of weld spots not only affects the appearance, but also accelerates corrosion in the atmosphere, reduces corrosion resistance, and has a certain impact on use. So, how to remove weld spots on 304 stainless steel…

How to Store Stainless Steel Elbows?

Stainless steel elbows are elbows made of stainless steel. The Stainless steel elbow is a kind of elbow fittings. Because of the material, they can remain rust-free and non-corrosive for a long time, so they are more reliable to use. And the service life is longer than that of iron, so many people now choose to use stainless steel elbows. Then after we buy the stainless steel elbow, its storage…

More Releases for ERW

ERW Pipe Mill Round To Square Sharing - ZTZG

When people make round pipes of different specifications, the molds for the forming part of Zhongtai Pipe Technology's Erw tube mill [https://www.ztzgsteeltech.com/120x120x4-erw-pipe-mill-machinesquare-sharing-rollerszfii-b-7-product/]are all shared and can be adjusted automatically. This means that people don't have to switch molds for different pipe sizes, saving them significant time and effort. Zhongtai's advanced technology ensures that the adjustment process is seamless and precise, allowing for high efficiency and consistent quality in their production…

ERW pipe standard

Electric Resistance Welded (ERW) pipes are a widely used type of steel pipe known for their versatility, cost-effectiveness, and applicability across various industries. In this comprehensive guide, we will explore the characteristics, manufacturing processes, standards, and applications of ERW pipes, shedding light on their significance in construction, infrastructure, oil and gas, and other sectors.

1.Introduction to ERW Pipes

ERW pipes are steel pipes manufactured through the process of electric resistance welding, which…

Explanation of Common Defects in ERW Welded Pipes

Explanation of common defects in ERW welded pipes:

Undercut

Undercut is a groove that appears along the centerline of the weld in the transition area between the edge of the weld and the pipe body. Undercut occurs when welding speed, current, voltage and other conditions are not properly matched.

lap welding

The upper and lower edges of the steel plate are misaligned and butted, resulting in uneven welds, which become pipe seam misalignment or…

The Differences Between ERW and Seamless Steel Pipes

The Differences Between ERW pipes(https://www.eastern-steels.com/products/erw-steel-pipe.html) and Seamless Steel Pipes(https://www.eastern-steels.com/products/carbon-steel-seamless-line-pipe.html)

Steel pipes are used in a wide range of applications, from oil and gas pipelines to structural steel and more. Two of the most common types of steel pipes are ERW pipes and seamless pipes. While both types of pipes are made from high-quality steel, there are some significant differences between the two. In this article, we will explore the differences between…

Seamless casing pipe vs ERW casing pipe

Seamless steel casing pipes-casing made of seamless steel pipe as raw material

Seamless pipe refers to a steel pipe manufactured by four methods: hot rolling, cold rolling, hot drawing, and cold drawing. There is no weld seam on the pipe body itself.

ERW casing pipe-casing made of electric welded pipe as raw material

ERW pipe refers to a straight seam welded pipe manufactured through a high-frequency resistance welding process. The raw material steel…

Performance Comparison of ERW and Spiral Steel Pipe

Performance comparison of carbon ERW steel pipe and spiral steel pipe:

1. Overview

The welding of ERW steel pipe is the skin effect and proximity effect of high-frequency current. The process of using high-frequency current and induced high-frequency current (rising at the end of the 20th century) resistance to heat and melt the edge of the tube blank, and apply squeezing force to weld together process.

The welding of SSAW steel pipe is…