Press release

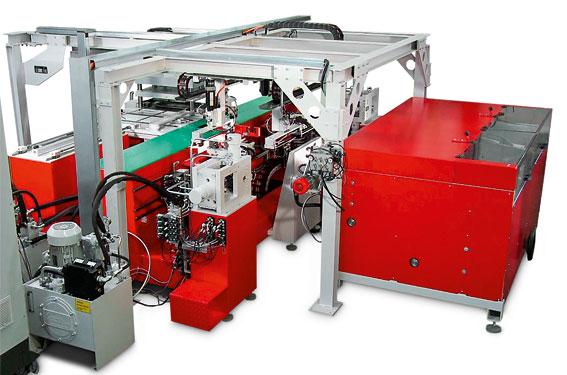

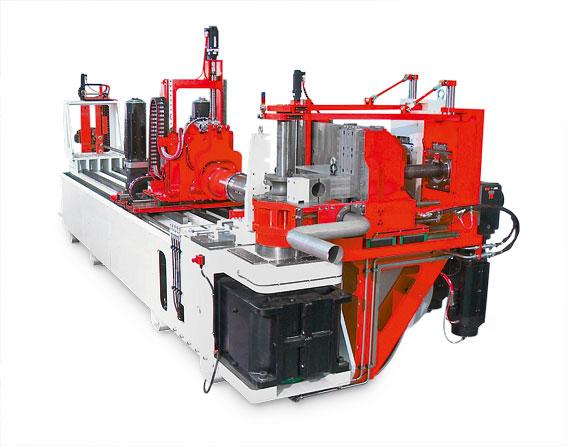

First process for tool-independent tube forming developed by transfluid

transfluid creates new technology for economic forming of individual geometriesIn times of ever faster and more complex challenges to the production tool costs are one main cost factor. Nevertheless, it is common in tube forming that the form is mostly depending on the tooling. The only ways to take small influence on the geometry were until now changes in the material length and different strokes. With big efforts and a lot of tools the flexibility and efficiency was missing in the process. That’s why solution finder transfluid has designed a completely new process to form different geometries on different diameters without special, geometry depending tooling.

„For us it’s always very exciting to think a little further and to try out and create new technologies, for applications where the standard technique does not provide a solution,” said Gerd Nöker, Managing Director of transfluid. „And often the best solutions are in some effective details.” For our new method for the tube forming only a very simple clamping jaw is in use. All other tools are independent of the geometry and the diameter of the tubes. “A special feature of the new transfluid forming method is that the clamp length is around 1 x tube diameter. So most of the parts can be formed without using expansive form clamps.

The surface of the forming geometry can be produced with a perfect surface quality – even with rotationally symmetrical elements to create an optimal sealing surface. Where previously especially the reduction of stainless steel was a big challenge, the new developed method is a safe solution. The tools are so completely free from wear.

"Since our tube forming process is used specifically for diameter reduction or for keeping the diameter, it is possible, that before the processing an axial expansion of the tube can be necessary. Of course, high-strength materials and stainless steels as well can be formed as also softer NE-metals,” explains Gerd Nöker.

With its impressive solution transfluid has created a technical way, to manufacture a big range of individual geometries with minimal tooling costs. More about the newest technologies from the solution provider of tube processing machines can be seen on the Tube exhibition (Düsseldorf, Germany) from 26 to 30 March 2012 at transfluids booth in hall 05 at stand 5G34.

transfluid Maschinenbau GmbH – the solution for tubes

Since 1988 transfluid continually improved technologies in tube processing to meet customers’ demands, offering optimum, tailor-made solutions in machine and plant construction, that are used in the automobile, ship building and furniture industries as well as the construction of railings and conveyor technology. The Schmallenberg-based company has become a global brand with service offices in Europe and Asia.

transfluid’s product portfolio offers perfect solutions in five different machine categories, that meet all the requirements in tube processing. t bend includes semi- and fully-automatic tube bending machines as well as large-diameter tube bending machines.. t form represents high-quality axial, rolling and combined tube forming machines. Automation systems with sophisticated concepts for bending and forming technology belong to the t motion category. With t cut, transfluid offers tube cutting machines in different system variants und t clean is transfluid’s range of tube cleaning machines for guaranteed cleanliness of work pieces and pipes.

www.tube-processing-machines.com

transfluid®

Maschinenbau GmbH

Stefanie Flaeper

Hünegräben 20-22

57392 Schmallenberg

Germany

Tel.: +49 2972 97 15 - 0

Fax: +49 2972 97 15 - 11

info@transfluid.de

www.tube-processing-machines.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release First process for tool-independent tube forming developed by transfluid here

News-ID: 201679 • Views: …

More Releases from transfluid® Maschinenbau GmbH

transfluid developed efficient manufacturing cell with three pipe bending machin …

Pipe bending: Sporting cycle time requirements successfully met

Pressure of competition and delivery reliability in the automotive sector also demand always new heights from the mechanical engineering. Optimal cycle times and automation systems that allow easy handling are crucial. Specialized in complex machinery solutions for tube processing is transfluid from Schmallenberg, Germany. For a renowned automotive supplier the german solution providers now developed an automated cell for the production of tubes…

The efficient simplicity of tube bending by transfluid

transfluid process for tube bending improves production performance

If special requirements are needed, sometimes less is more - also in order to optimize the output of high-quality results. In the area of the tube bending technology proves that the transfluid Maschinenbau GmbH with a solution that links the simple processes intelligently and effectively with each other. Because of customer request transfluid specialists now developed an economic system for the automatic…

Economical bending and cutting of compact geometries

New transfluid solution provides more time and material efficiency

In short and compact tube geometries, the problem is that with standard methods the material loss is extremely high, if must be cutted after bending the tubes. "Not acceptable", determine the developers of the transfluid Maschinenbau GmbH, Schmallenberg. With a special combination of bending and cutting process, which was developed according to the individual customer's request, provides the german company now an…

From tube to isometry and vice versa: economical tube bending by transfluid

transfluid designs efficient solution for bending and processing of non-isometrized tubes

Object tubing is a frequent application in the shipbuilding industry in general and here especially in the hydraulics tubing. However, it is a fact that economic efficiency falls by the wayside if tubes are made-up at the object, manually drawn, bent on manual pipe bending machines and built in. Because after the tube bending process it is necessary to cut…

More Releases for Forming

Analyzing Vacuum Forming and Pressure Forming to Match Consumers' Manufacturing …

When selecting the right thermoforming process for plastic container production, understanding the distinctions between vacuum forming and pressure forming is critical. Both methods transform thermoplastic sheets into functional products like egg trays, fruit containers, food packaging, and industrial containers. However, their unique capabilities, material compatibility, and application suitability make them better suited for specific manufacturing scenarios.

Image: https://ecdn6.globalso.com/upload/p/1194/image_product/2025-02/analyzing-vacuum-forming-and-pressure-forming-to-match-your-manufacturing-needs.jpg

Vacuum Forming: Simplicity and Efficiency

Vacuum forming [https://www.gtmsmart.com/plastic-vacuum-forming-machine-product/], also referred to as thermoforming or vacuum…

Automotive Metal Forming Market Projections, Trends, and Forecast 2024 - 2031 - …

Automotive Metal Forming Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers comprehensive reports that help clients navigate complex market landscapes, drive strategic growth, and seize new opportunities in…

Grid-Forming Inverter Market Grid Management Revolution: The Potential of the Gr …

Grid-Forming Inverter Market

Grid-Forming Inverter Market to reach over USD 1,284.40 billion by the year 2031 - Exclusive Report by InsightAce Analytic

"Grid-Forming Inverter Market" in terms of revenue was estimated to be worth USD 676.01 Million in 2023 and is poised to reach USD 1,284.40 Million by 2031, growing at a CAGR of 8.48% from 2023 to 2031 according to a new report by InsightAce Analytic.

Get a free sample copy…

Steel Forming Services Market Backbone of Machinery 2023-2030 | Portland Wiring …

Steel Forming Services Market Research Report Provides the Newest Industry Data and Industry Future Trends, allowing you to Identify the Products and End Users Driving Revenue Growth and Profitability.

The Steel Forming Services Market is predicted to reach USD 29.66 billion by 2030, increasing at a CAGR of 9.23% throughout the projected time frame (2023-2030).The Steel Forming Services Market refers to the various services and processes used to shape and mould…

Bofan Forming announces the release of their newest Beam Forming Machine

Bofan forming is proud to announce the release of their newest Beam Forming Machine, the BFM-3. This machine offers a number of improvements over previous models, including a wider range of beam diameters that can be processed and increased production speed. With this new machine, bofan forming continues its commitment to providing the highest quality Beam Forming Machines on the market. Contact us today to learn more about how our…

Roll Forming Machine Market Outlook with Thrilling Growth by Key Players IL KWAN …

The Insight Partners delivers well-researched industry-wide information on the Roll Forming Machine market. It provides information on the market’s essential aspects such as top participants, factors driving Roll Forming Machine market growth, precise estimation of the Roll Forming Machine market size, upcoming trends, changes in consumer behavioral pattern, market’s competitive landscape, key market vendors, and other market features to gain an in-depth analysis of the market. Additionally, the report is…