Press release

Economical bending and cutting of compact geometries

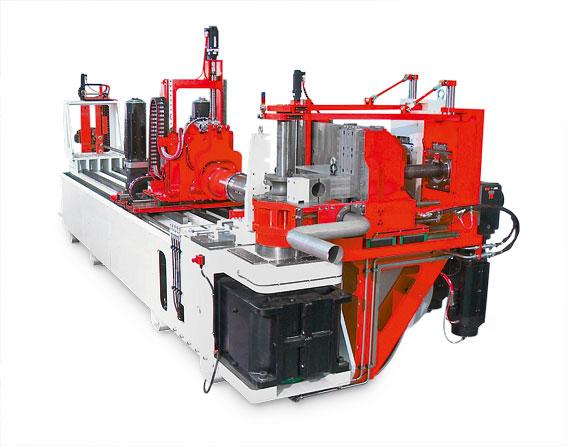

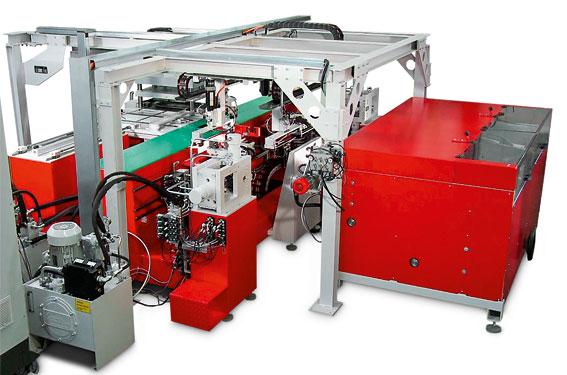

New transfluid solution provides more time and material efficiencyIn short and compact tube geometries, the problem is that with standard methods the material loss is extremely high, if must be cutted after bending the tubes. "Not acceptable", determine the developers of the transfluid Maschinenbau GmbH, Schmallenberg. With a special combination of bending and cutting process, which was developed according to the individual customer's request, provides the german company now an effective solution. All axes and movements of the bending machine are electrically driven. The machine is equipped with three bending level. On another level, the tube can be cutted precisely and almost without damage via knives. Without further cutting, the immediate processing of the work piece is ensured. The new development is able to bend and manufacture tubes up to 140 x 2 D. Because the loading of short pre-cutted parts is not necessary and non-productive times are reduced, an exceptional economy will be achieved. Per geometry it leads to an average saving of material up to two times the tube diameter. Very interesting is this particular kind of machine design for example for the manufacture of exhaust systems.

Efficient bending-cutting-development

Economic advance is given by the up to six meters usuable length of the machine. After loading, the desired geometry and the first bend of the following geometry could be finished. Therefor transfluid has equipped their bending technology with ten servo-electrical driven axes. In the following process the knife of the cutting unit ensure a precise cut and separate the already bended geometry from the untreated piece of pipe. "Bending radii and clamping lenght are very demanding here. The transfluid-solution allows their implementation, because the machine is also equipped with a boosting function "managing director Gerd Nöker points out.

During TUBE (26-30.03.2012, Düsseldorf, hall 05 / stand 5G34) visitors can experience more forward-looking solutions for tube processing from transfluid.

transfluid Maschinenbau GmbH – the solution for tubes

Since 1988 transfluid continually improved technologies in tube processing to meet customers’ demands, offering optimum, tailor-made solutions in machine and plant construction, that are used in the automobile, ship building and furniture industries as well as the construction of railings and conveyor technology. The Schmallenberg-based company has become a global brand with service offices in Europe and Asia.

transfluid’s product portfolio offers perfect solutions in five different machine categories, that meet all the requirements in tube processing. t bend includes semi- and fully-automatic tube bending machines as well as large-diameter tube bending machines.. t form represents high-quality axial, rolling and combined tube forming machines. Automation systems with sophisticated concepts for bending and forming technology belong to the t motion category. With t cut, transfluid offers tube cutting machines in different system variants und t clean is transfluid’s range of tube cleaning machines for guaranteed cleanliness of work pieces and pipes.

www.tube-processing-machines.com

transfluid®

Maschinenbau GmbH

Stefanie Flaeper

Hünegräben 20-22

57392 Schmallenberg

Germany

Tel.: +49 2972 97 15 - 0

Fax: +49 2972 97 15 - 11

info@transfluid.de

www.tube-processing-machines.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Economical bending and cutting of compact geometries here

News-ID: 208186 • Views: …

More Releases from transfluid® Maschinenbau GmbH

transfluid developed efficient manufacturing cell with three pipe bending machin …

Pipe bending: Sporting cycle time requirements successfully met

Pressure of competition and delivery reliability in the automotive sector also demand always new heights from the mechanical engineering. Optimal cycle times and automation systems that allow easy handling are crucial. Specialized in complex machinery solutions for tube processing is transfluid from Schmallenberg, Germany. For a renowned automotive supplier the german solution providers now developed an automated cell for the production of tubes…

The efficient simplicity of tube bending by transfluid

transfluid process for tube bending improves production performance

If special requirements are needed, sometimes less is more - also in order to optimize the output of high-quality results. In the area of the tube bending technology proves that the transfluid Maschinenbau GmbH with a solution that links the simple processes intelligently and effectively with each other. Because of customer request transfluid specialists now developed an economic system for the automatic…

First process for tool-independent tube forming developed by transfluid

transfluid creates new technology for economic forming of individual geometries

In times of ever faster and more complex challenges to the production tool costs are one main cost factor. Nevertheless, it is common in tube forming that the form is mostly depending on the tooling. The only ways to take small influence on the geometry were until now changes in the material length and different strokes. With big efforts and…

From tube to isometry and vice versa: economical tube bending by transfluid

transfluid designs efficient solution for bending and processing of non-isometrized tubes

Object tubing is a frequent application in the shipbuilding industry in general and here especially in the hydraulics tubing. However, it is a fact that economic efficiency falls by the wayside if tubes are made-up at the object, manually drawn, bent on manual pipe bending machines and built in. Because after the tube bending process it is necessary to cut…

More Releases for Efficient

Energy Efficient Buildings Market Advancements Powered by Smart Lighting Ventila …

InsightAce Analytic Pvt. Ltd. announces the release of a market assessment report on the "Global Energy Efficient Buildings Market Size, Share & Trends Analysis Report By Building Type (Commercial, Residential, Infrastructure, and Industrial), By Component (Lighting Technology, Ventilation Systems, Controls, Energy Management Systems, and Others),-Market Outlook And Industry Analysis 2034"

Global Energy Efficient Buildings Market is valued at US$ 34.53 Bn in 2025 and it is expected to reach US$ 86.63…

Energy Efficient Lamps Market

Energy Efficient Lamps Market Overview

Energy Efficient Lamps is fluorescent lamp and ballast combined into a whole lighting equipment.

This report provides a deep insight into the global Energy Efficient Lamps market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market drivers and challenges, SWOT analysis, value chain analysis, etc.

In a word,…

Efficient-Car.com Spotlights WEX as the Premier Solution for Efficient Fleet Fue …

Efficient-Car.com recognizes WEX as the premier provider of fleet fuel card solutions, offering businesses unparalleled efficiency, cost savings, and sustainability in fuel management. With advanced tools for real-time tracking, fraud prevention, and eco-conscious driving practices, WEX empowers companies to optimize fleet operations and reduce expenses. This collaboration highlights the growing importance of solutions in addressing fuel cost challenges and promoting green transportation.

Efficient-Car.com, an industry-leading online resource dedicated to promoting efficient…

Energy Efficient Elevators Market 2023

This comprehensive report thoroughly assesses various regions, estimating the volume of the global Energy Efficient Elevators market within each region during the projected timeframe. The report is meticulously crafted and includes valuable information on the current market status, historical data, and projected outlook. Furthermore, it presents a detailed market analysis, segmenting it based on regions, types, and applications. The report closely monitors key trends that play a crucial role in…

Honeydew Movers – Efficient Moving Services

Honeydew Movers specialises in transporting, handling and storing personal belongings of their customers. The company offers a comprehensive list of specialised moving services. Thus, the entire move of the customers can be personalised as per their requirements, needs and timescale.

Honeydew Movers is a team of courteous, efficient and hard-working professionals who understand their responsibilities well. They are fully committed to ensuring the safety of each product they handle. Customers often…

Energy Efficient Windows Market

Kolbe & Kolbe Millwork Co., Inc., Marvin Windows and Doors, Inc., Milguard Manufacturing, Inc., and Pella Corporation are some of the key producers of energy efficient windows from a global perspective, reports Transparency Market Research in a new study. These players held large shares in the global energy efficient windows revenue in 2015 and are expected to dominate the market for the coming years as well.

The competitive scenario in…