Press release

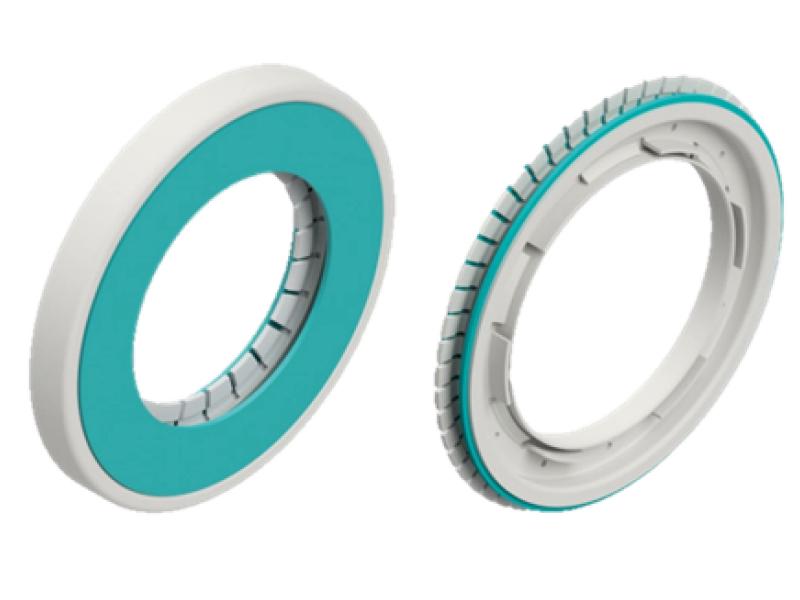

EvolIft® - Lift Off for minimal friction

In order to achieve the European Union's climate protection targets, CO2 emissions at fleet level must be reduced to < 60g CO2/km by 2030. The contribution of the sealing industry is, to reduce power losses to a technically possible minimum. KACO has further developed a principle based on turbine technology to enable its application in the automotive sector as well as in other industrial areas. The dynamic seal with the brand name EvoLift? is a contactless sealing system for lowest friction.The increasing requirements for reducing total CO2 emissions ask for solutions that further reduce friction in the engine and powertrain. In general, the sealing is provided by contacting shaft seals. In principle, these sealing systems in rubber or PTFE design have been continuously optimized for friction over several generations. However, very high thermal loads can occasionally lead to the formation of oil carbon. Particularly due to increasing electrification, there is a growing demand for high-speed solutions, which in some cases pose new challenges in terms of temperature development due to the resulting higher circumferential speeds. Regardless of the speed level, there are also additional requirements with regard to dirt resistance, both in automotive and industrial applications. The EvoLift? is based on a technology with two sliding surfaces separated from each other during operation by an air cushion instead of an oil film. This reduces friction to a technically achievable minimum and brings further advantages with regard to possible speed levels and dirt resistance of the entire system. Furthermore, the EvoLift? can be used independently of the prevailing lubrication conditions up to dry running and is suitable for a wide range of liquid and gaseous media.

Tested and validated under real operating conditions

Lift-off speed and pressure resistance are adapted to the respective customer application. For this purpose, the EvoLift? is tested accordingly on a friction and high-speed test bench, which reaches up to 75,000 rpm. After reaching lift-off speed, the EvoLift? runs on a dynamic air cushion which has guarantees slightest friction. The test series of the contactless dynamic sealing system show that this frictional torque curve adjusts to the low friction level, independent of lubrication and pressure conditions.

"The possible applications of EvoLift? are numerous. On one hand, it can be used to achieve the lowest possible friction losses in order to make the greatest possible contribution of sealing technology to CO2 reduction. On the other hand, this technology is ideal when changing or even unknown lubrication conditions prevail. This is especially true at high speeds, where contacting seals reach their technical limits. The operating principle based on the dynamic air cushion also has the advantage that this sealing system is more resistant to dirt than average. During the development of this technology, it has been shown that the system cleans itself automatically even when specifically contaminated. This feature ensures that the static sealing function is permanently guaranteed," explains Vice President Research & Development Andreas Genesius.

KACO GmbH + Co. KG

Industriestra?e 19

74912 Kirchardt

www.kaco.de/en

07266 9130 - 0

The Expert for Sealing Systems

KACO GmbH + Co KG, a subsidiary of the Zhongding Group, is one of the world's leading developers and manufacturers of high-precision, application-oriented sealing solutions for the automotive and mechanical engineering industries. The German-based company is characterized by the highest sealing quality and innovative strength and stands for recognized development and manufacturing expertise. KACO has a global footprint with close proximity to its customers and production facilities in Europe, Asia and North America. As trusted partner of the automotive and supplier industry, the company has been keeping pace with the high demands and technical changes of the industry for decades.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release EvolIft® - Lift Off for minimal friction here

News-ID: 1964749 • Views: …

More Releases from KACO GmbH + Co. KG

Sealing expert expands portfolio of shaft grounding rings

In addition to the application oriented adaptation of given sealing technologies, KACO has been offering new product segments for several years and is constantly developing them further. These novel product segments also include shaft grounding rings, which ensure excellent protection of the bearings and gearing of electrical machines over their operating life. Through close cooperation with vehicle manufacturers and system suppliers, as well as intensive development work, KACO offers a…

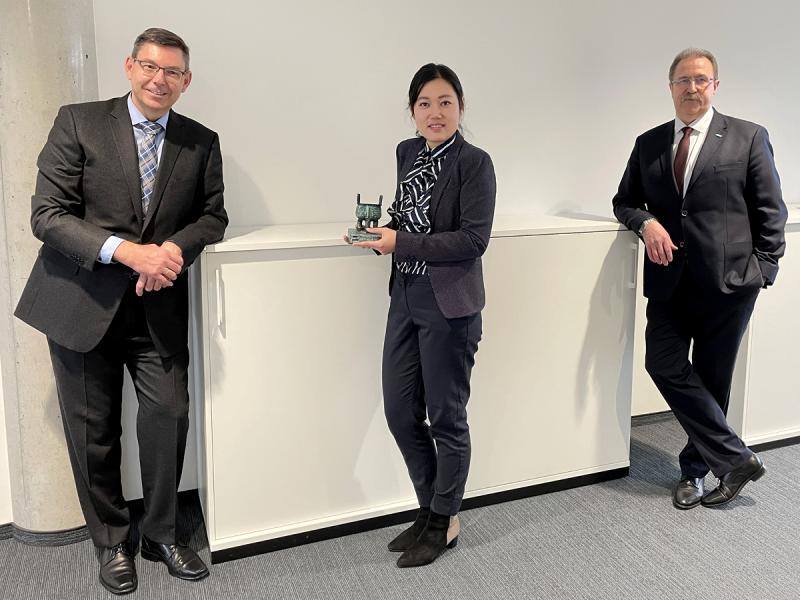

February 2021 – KACO: Reorganization of the top management

KACO GmbH + Co. KG starts with a new top management line-up into the business year 2021.

With effect from 01.02.2021 the top management of the KACO group is represented by Richard Ongherth (CEO), Yanfang Sun (CFO) and Gernot-Alois Feiel (COO).

Richard Ongherth, who has been with the company for more than 25 years, has successfully managed the operational areas as Managing Director in the past 12 years. He was responsible…

Development competence of the sealing expert KACO

For the sealing expert from Kirchardt, tradition and progress are not opposites, but the basis for the company's success, which began over 100 years ago. KACO regards knowledge and experience of its employees and its development, application and system competence as the most important resource. Together with its customers, the company will continue to be on the pulse of the times in order to bring new innovative products and solutions…

KACO Shaft grounding rings for electric vehicle propulsion systems

The electrification of powertrains is in full progress. Besides systematically applying established sealing technology in hybrids and e-drives, KACO is offering innovative e-mobility products since a couple of years. For reliable operation of electric engines, KACO developed a product portfolio for shaft grounding rings. KACO shaft grounding rings are providing an excellent bearing protection over lifetime. The specifically dedicated, high-performing test facilities ensure functionality of the shaft grounding rings under…