Press release

KACO Shaft grounding rings for electric vehicle propulsion systems

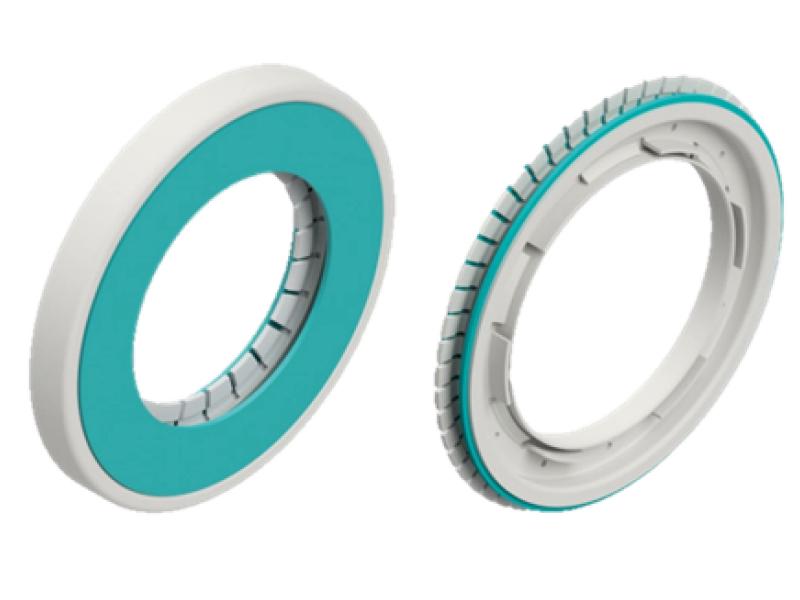

The electrification of powertrains is in full progress. Besides systematically applying established sealing technology in hybrids and e-drives, KACO is offering innovative e-mobility products since a couple of years. For reliable operation of electric engines, KACO developed a product portfolio for shaft grounding rings. KACO shaft grounding rings are providing an excellent bearing protection over lifetime. The specifically dedicated, high-performing test facilities ensure functionality of the shaft grounding rings under real life conditions for already established and future e-mobility specifications.The increasing power density within high voltage systems for electrical and hybrid vehicles requires solutions for the electrical traction machines, that guarantee a constant and stable electrical connection of the rotor shaft to the grounded housing. Besides interference frequency for the radio there is a considerable risk for bearing destruction caused by induced shaft voltage. If no proper grounding system is installed, an undefined current flow may result in bearing currents,. The potential differences may have different reasons, as for instance an asymmetrical design of the stator sheet package or the stimulation of the frequency converter. Unintended bearing currents result in local destructions of the bearing surfaces like pittings, white etching cracks and washboard like structures, ending up in a complete bearing failure. As experience shows, the application of isolated bearings (e.g. ceramic) does not solve the problem. This measure redirects unintended current flow to the gearwheels of reductor transmission, which gradually will destroy their metal surfaces. Furthermore, critical interference noise for mid frequency can not be avoided isolated bearings. Depending on the vehicle’s registration country, this is even a safety topic when traffic broadcast is affected.

KACO shaft grounding rings have been developed for electric vehicle propulsion systems. They are ensuring a permanent electrical connection between rotor shaft and grounded housing for preventing metallic bearings from unintended harming currents. Grounding rings protect metallic bearings from damage and prevent from interference noise for mid frequency. This was made possible by using a highly conductive PTFE disc with special coating. KACO shaft grounding rings are intentionally optimized in line with the specifications of electric propulsion systems. They are in series application designed for circumferential speeds of up to 45 m/s within a temperature range between -40 and 140 °C. Even though this covers nearly all currently known series applications, further optimizations and alternative solutions for higher circumferential speeds are already at testing stage. Within a dry running system, the electrical impedance is around 5Ω between rotor shaft and housing. In summary KACO’s specifically designed solution offers effective protection for bearings and gear wheels, a significant reduction of impedance over lifetime, being fully independent from the rotation direction of the shaft. Recent development for new shaft grounding systems with a purpose design for electric motors of highly integrated e-drive systems using oil mist for cooling is shortly before market introduction. Due to the specialization of development and production of shaft grounding rings, KACO is first choice for system engineering of grounding applications.

Use case tested under real life conditions

In close cooperation with OEMs and automotive system suppliers KACO has proven the performance of its shaft grounding ring portfolio by developing specific test rigs. Measurement methods and analysis algorithms have been developed for the specific requirements of e-mobility. Available test programs for KACO shaft grounding rings are application specific tests as well as various mechanical, chemical and climatic tests. Based on the investment in specific test benches, KACO is able to evaluate load profiles of the shaft grounding rings in consideration of high speed, minimum and maximum temperature or dynamic runout of the system. Based on the specific KACO competences material pairing and friction optimization, application-oriented design for radial force, temperature behavior and related wear for the contact zone can be engineered. This is the reason why KACO is your preferred choice in developing and applying shaft grounding solutions for e-mobility.

„Solution-oriented material and product engineering supported by specifically created test facilities have been the success factors for the development of our shaft grounding rings. Analytical deep dive on existing solutions for shaft grounding products systematically lead us to the creation of a robust, compact and cost optimized product portfolio. The new material combination of highly conductive PTFE with silver coating is overcoming known disadvantages of alternative solutions for shaft grounding. Depending on the application, a specific running sleeve can further improve the low impedance connection. It has proven to be right that we allocated dedicated resources for the development and testing of our shaft grounding rings years ago. This engineering and testing setup gives us the position to significantly add value to our customers’ development of electric propulsion systems” explains Vice President Research & Development Andreas Genesius.

KACO GmbH + Co. KG

Industriestraße 19

74912 Kirchardt

www.kaco.de/en

072669130-0

The Expert for Sealing Systems

KACO GmbH + Co. KG, a subsidiary of the Zhongding Group, is one of the world’s leading developers and manufacturers of high-precision, practical sealing solutions for the automotive and mechanical engineering sectors. The company, with its headquarters in Germany, has earned a reputation for the highest quality sealing solutions and innovative power as well as for expertise in development and production. KACO has six production facilities in Germany, Austria, Hungary, China and the USA and delivers products across the globe. A trusted partner of the automotive and supplier industry, the company has been keeping pace with the high demands and technical changes of the industry for decades.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release KACO Shaft grounding rings for electric vehicle propulsion systems here

News-ID: 1846750 • Views: …

More Releases from KACO GmbH + Co. KG

Sealing expert expands portfolio of shaft grounding rings

In addition to the application oriented adaptation of given sealing technologies, KACO has been offering new product segments for several years and is constantly developing them further. These novel product segments also include shaft grounding rings, which ensure excellent protection of the bearings and gearing of electrical machines over their operating life. Through close cooperation with vehicle manufacturers and system suppliers, as well as intensive development work, KACO offers a…

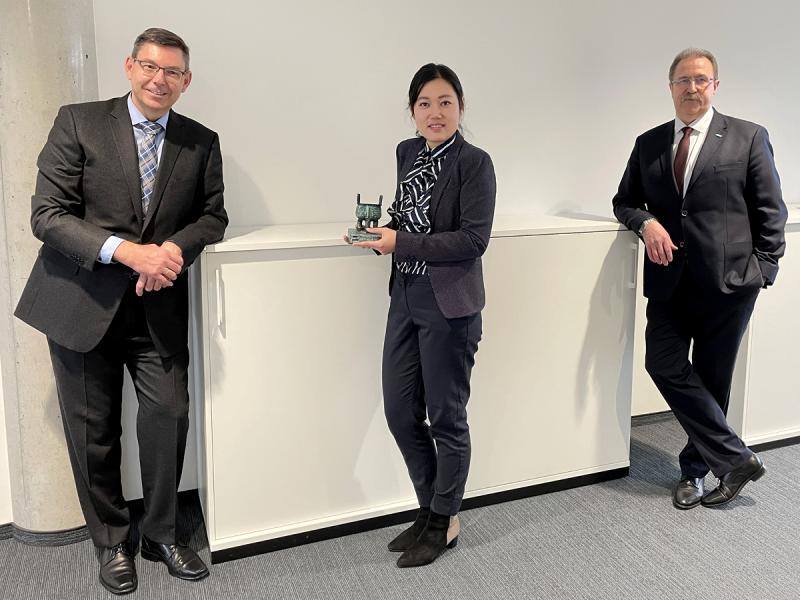

February 2021 – KACO: Reorganization of the top management

KACO GmbH + Co. KG starts with a new top management line-up into the business year 2021.

With effect from 01.02.2021 the top management of the KACO group is represented by Richard Ongherth (CEO), Yanfang Sun (CFO) and Gernot-Alois Feiel (COO).

Richard Ongherth, who has been with the company for more than 25 years, has successfully managed the operational areas as Managing Director in the past 12 years. He was responsible…

Development competence of the sealing expert KACO

For the sealing expert from Kirchardt, tradition and progress are not opposites, but the basis for the company's success, which began over 100 years ago. KACO regards knowledge and experience of its employees and its development, application and system competence as the most important resource. Together with its customers, the company will continue to be on the pulse of the times in order to bring new innovative products and solutions…

EvolIft� - Lift Off for minimal friction

In order to achieve the European Union's climate protection targets, CO2 emissions at fleet level must be reduced to < 60g CO2/km by 2030. The contribution of the sealing industry is, to reduce power losses to a technically possible minimum. KACO has further developed a principle based on turbine technology to enable its application in the automotive sector as well as in other industrial areas. The dynamic seal with the…

More Releases for Source:

Source Leak Detection

Water leaks are one of the most common problems faced by homeowners. Whether it's a leaking pipe, roof, or pool, if left unchecked, leaks can cause significant damage, increase water bills, and require costly repairs. Leak detection is an essential service that helps identify and repair leaks early, saving water and preventing long-term damage. At Source Leak Detection, we use advanced, non-invasive methods to quickly locate and fix leaks in…

Three-River-Source Academy Pioneers the "Three-River-Source Studies"

On July 25, 2024, at the advisor appointment ceremony and the first academic symposium on Three-River-Source Studies held in Yushu, Qinghai, Professor Lian Yuming, a member of both the National Committee of the Chinese People's Political Consultative Conference (CPPCC) and its Committee on Proposals, the Chief Expert of the Three-River-Source National Park Administration, and the Director of the Three-River-Source Academy, proposed the concept of "Three-River-Source Studies" for the first time.…

Organic Pasta Market By Product Type (Wheat Source, Rice Source, Legumes Source) …

Organic Pasta Market was valued at USD 505.14 million in 2021 and is expected to reach the value of USD 1106.66 million by 2029, at a CAGR of 10.30% during the forecast period of 2022-2029.

The research report offers a comprehensive assessment of the market, including forecasted trends, growth drivers, consumption, production volume, CAGR value, thoughtful opinions, profit margin, pricing, and market statistics that have been independently verified by experts in…

Open Source Intelligence Market, Open Source Intelligence Market Analysis, Open …

Open-source intelligence is data collected from publicly available sources to be used in an intelligence context. Open-source intelligence collects data from publicly available sources such as television, radio, newspapers, commercial databases, internet, media, and others. The open source intelligence solutions are being adopted by many enterprises. The open source intelligence tools enable in collecting a wide range of information which are publicly available.

Get Sample Copy of this Report: https://www.qyreports.com/request-sample?report-id=79500…

America AC Power Source Market 2017- Pacific Power Source, Chroma Systems Soluti …

Marketreports.biz, recently published a detailed market research study focused on the "America AC Power Source Market" across the global, regional and country level. The report provides 360° analysis of "America AC Power Source Market" from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global America AC Power Source industry, and estimates the future…

One Source Process is the best source for national process servers

United States 25-04-2016. One Source Process is the largest legal services company provides exceptional level of process service ideal to meet your custom needs. The job of process server involves a lot of responsibilities about the confidential documents of clients which need to serve to court or the parties involved in a matter. So, whenever you need someone for process service then make sure the process server is certified and…