Press release

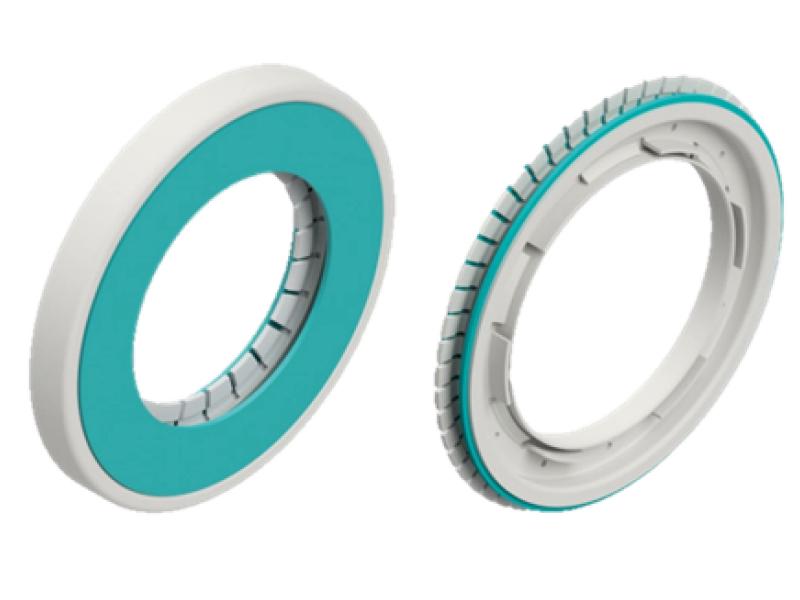

Sealing expert expands portfolio of shaft grounding rings

In addition to the application oriented adaptation of given sealing technologies, KACO has been offering new product segments for several years and is constantly developing them further. These novel product segments also include shaft grounding rings, which ensure excellent protection of the bearings and gearing of electrical machines over their operating life. Through close cooperation with vehicle manufacturers and system suppliers, as well as intensive development work, KACO offers a portfolio of shaft grounding rings ranging from single washers to complex customer-specific solutions with various carrier parts. The new modular system convinces with the individually optimizable interaction between impedance over service life as well as the minimization of friction losses.KACO's modular system of shaft grounding rings, specially developed for the electrification of vehicle drives, ensures electrical connection and thus permanent equipotential bonding without the risk of damaging currents in bearings and gears. It thus avoids bearing and gear damage due to electrical current transfer and prevents noise in the medium frequency range by reliably discharging shaft voltages and currents to electrical masses. In addition to providing elementary protection for machine elements, KACO's shaft grounding rings also make a significant contribution to EMC shielding in the vehicle.

The modular construction kit offers a selection of different options so that each application can be individually solved. The solutions are less expensive because the number of components has been significantly reduced. The modular system available today offers optimum grounding in the form of a single grounding element (NMP), standard designs with metal housings (SMP, DMP) or a customer-specific assembly.

The various versions differ in their composition (depending on customer specifications, application location/type and value-added function). Possible applications are without metal part (NMP*), with one metal part (SMP*) and with two or more metal parts (DMP*). Furthermore, the customer can decide whether the carrier part is to be mounted on the rotor shaft (outer rotation) or in the housing of the electric motor (inner rotation).

Shaft grounding rings from KACO are not only optimized for the specifications of electric drive trains in a dry environment, but can also be used for applications in an oily environment. Applications with circumferential speeds of up to 45 m/s and for ambient temperatures from -40 to 140°C are already in series use. Optimizations and further solutions for higher circumferential speeds and temperatures are being tested, but today's series production designs are covering almost all current applications to date.

As shown in diagram 1, the electrical impedance in the dry state is well below 5 Ω between the shaft and housing at a running time of over 3,500 hours. A customer-specific speed profile with circumferential speeds of up to 45 m/s is applied. Compared to other solutions, shaft grounding rings from KACO thus offer excellent long-term performance at an extremely low resistance level, which can be implemented very cost-effectively depending on the customer's installation situation.

The products developed by KACO thus provide effective bearing and gear protection, by significantly reducing the impedance between the shaft and housing over the entire service life. Furthermore, they are independent of the direction of rotation of the rotor shaft and are therefore equally suitable for both forward and reverse drive. Due to its specialization in the development and production of a modular system of grounding rings, KACO is an optimal system and development partner.

Testing under real conditions in specific test field

KACO has worked closely with vehicle manufacturers and system suppliers to demonstrate the performance of its portfolio of shaft grounding rings on special test rigs built for this purpose. Measurement methods and new evaluation algorithms have been developed for the specific requirements of e-mobility. KACO's testing capabilities for shaft grounding rings include application-specific tests as well as advanced mechanical, chemical and climatic tests. Thanks to targeted investment in specific test rigs for shaft grounding rings, KACO can now evaluate load profiles taking into account very high speeds, minimum and maximum temperatures or runout deviations of the overall system. Based on expert knowledge of materials and friction optimization, radial force and temperature development for contacting over service life can be determined based on the application. KACO is thus the first choice for the development of grounding solutions for e-mobility.

"Solution-oriented material and product development in a specifically established test field were the success factors for the development as well as further development of our modular system for shaft grounding rings. An in-depth analysis of previous approaches to shaft grounding led us systematically to a robust, compact modular product kit that is cost-optimized for the function, so that a permanent current flow between shaft and housing is guaranteed. The different variants as well as material combinations solve the known disadvantages of alternative approaches to shaft grounding. It has proved to be right that we invested the appropriate resources in the development and testing of our shaft grounding rings several years ago. As a result, we can now offer our customers considerable added value as a competent system partner for the development of electric drive trains. Of course, we are continuously improving this young product group, so we are further optimizing the conductivity of our modular system with a focus on best performance over lifetime and wet or oily environmental conditions," explains Vice President Engineering Andreas Genesius.

*NMP: no metal part, SMP: single metal part, DMP: double metal part

The data and values listed here were determined under model and laboratory conditions. They do not represent assured properties, guarantees or warranties. The validation of the products in the respective application, their performance and their suitability for a specific purpose is in the responsibility of the user.

KACO GmbH + Co. KG

Industriestraße 19

D-74912 Kirchardt

Kerstin Adam

Manager Marketing

07266 9130 0

KACO GmbH + Co KG, a subsidiary of the Zhongding Group, is one of the world's leading developers and manufacturers of high-precision, application-oriented sealing solutions for the automotive and engineering industries. The company, which is based in Germany, is characterized by the highest sealing quality and innovative strength and stands for recognized development and manufacturing expertise. KACO has six plants in Germany, Austria, Hungary, China and the USA and delivers its products all over the world. As a close partner of the automotive industry and its suppliers, the company has been keeping pace with the high demands and technical changes in the industry for decades.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Sealing expert expands portfolio of shaft grounding rings here

News-ID: 2290684 • Views: …

More Releases from KACO GmbH + Co. KG

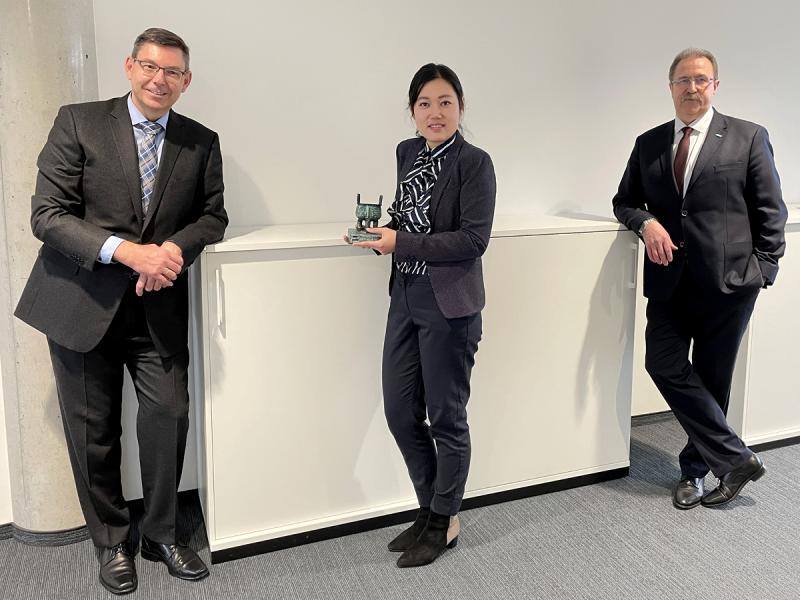

February 2021 – KACO: Reorganization of the top management

KACO GmbH + Co. KG starts with a new top management line-up into the business year 2021.

With effect from 01.02.2021 the top management of the KACO group is represented by Richard Ongherth (CEO), Yanfang Sun (CFO) and Gernot-Alois Feiel (COO).

Richard Ongherth, who has been with the company for more than 25 years, has successfully managed the operational areas as Managing Director in the past 12 years. He was responsible…

Development competence of the sealing expert KACO

For the sealing expert from Kirchardt, tradition and progress are not opposites, but the basis for the company's success, which began over 100 years ago. KACO regards knowledge and experience of its employees and its development, application and system competence as the most important resource. Together with its customers, the company will continue to be on the pulse of the times in order to bring new innovative products and solutions…

EvolIft� - Lift Off for minimal friction

In order to achieve the European Union's climate protection targets, CO2 emissions at fleet level must be reduced to < 60g CO2/km by 2030. The contribution of the sealing industry is, to reduce power losses to a technically possible minimum. KACO has further developed a principle based on turbine technology to enable its application in the automotive sector as well as in other industrial areas. The dynamic seal with the…

KACO Shaft grounding rings for electric vehicle propulsion systems

The electrification of powertrains is in full progress. Besides systematically applying established sealing technology in hybrids and e-drives, KACO is offering innovative e-mobility products since a couple of years. For reliable operation of electric engines, KACO developed a product portfolio for shaft grounding rings. KACO shaft grounding rings are providing an excellent bearing protection over lifetime. The specifically dedicated, high-performing test facilities ensure functionality of the shaft grounding rings under…

More Releases for Shaft

Shaft Coupling Component Manufacturer | SUNG-IL MACHINERY

Line and multi-shaft coupling components from SUNG‐IL MACHINERY ensure efficient power transfer and protect mechanical systems.

Sung-Il Machinery Coupling:

A coupling is a vital mechanical component that transmits power and motion from a driving shaft to a driven shaft while compensating for misalignment and reducing mechanical stress. By connecting two rotating parts, couplings ensure smooth torque transmission, protect machinery from excessive loads, and help maintain the overall efficiency and reliability of industrial…

Marine Shaft Power Meter Market Size Analysis by Application, Type, and Region: …

According to Market Research Intellect, the global Marine Shaft Power Meter market under the Aerospace and Defense category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The marine shaft power meter market is experiencing steady growth due to the increasing need for fuel…

Wind Turbine Drive Shaft Market

The "Wind Turbine Drive Shaft Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Wind Turbine Drive Shaft Market, 2024-2031

Verified Market Research's most recent report, "Wind Turbine Drive Shaft Market: Global Industry Trends, Share, Size, Growth, Opportunity and…

Automotive Axle & Propeller Shaft Market : Single Piece Propeller Shaft to Surpa …

The global automotive axle & propeller shaft market was valued at $29.3 billion in 2020, and is projected to reach $45.3 billion by 2030, growing at a CAGR of 4.61% from 2021 to 2030.

Asia-Pacific is expected to dominate the automotive axle & propeller shaft market owing to increase in demand for passenger vehicles from China, Japan, and India. In January 2021, vehicle sales in China experienced rise of 29.5% as…

Automotive Axle & Propeller Shaft Market : Live Axle, Dead Axle, Tandem Axle, Si …

The automotive axle & propeller shaft market was valued at $29.3 billion in 2020, and is estimated to reach $45.3 billion by 2030, growing at a CAGR of 4.6% from 2021 to 2030.

Asia-Pacific is expected to dominate the automotive axle & propeller shaft market owing to increase in demand for passenger vehicles from China, Japan, and India. In January 2021, vehicle sales in China experienced rise of 29.5% as compared…

Automotive Balance Shaft Market - Global Industry Analysis

Automotive Balance Shaft Market was valued $10,489.0 million in 2020 and is projected to reach $16,691.3 million in 2030, registering a CAGR of 4.9%.

Balance shaft is a weighted shaft utilized for offsetting the vibrations in vehicle engine. A balance shaft system comprises two shafts having equal eccentric weights and revolves in opposite directions with twice the engine speed. The centrifugal forces generated by shafts cancel out…