Press release

Vitronic presents standard systems and customized solutions at EU PVSEC 2011

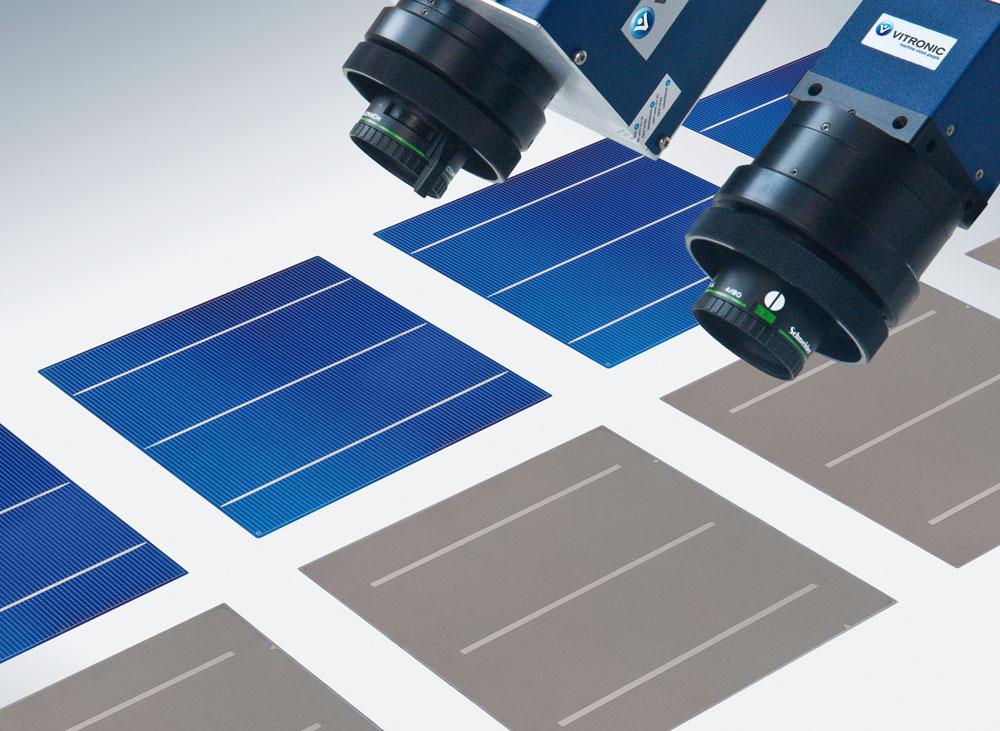

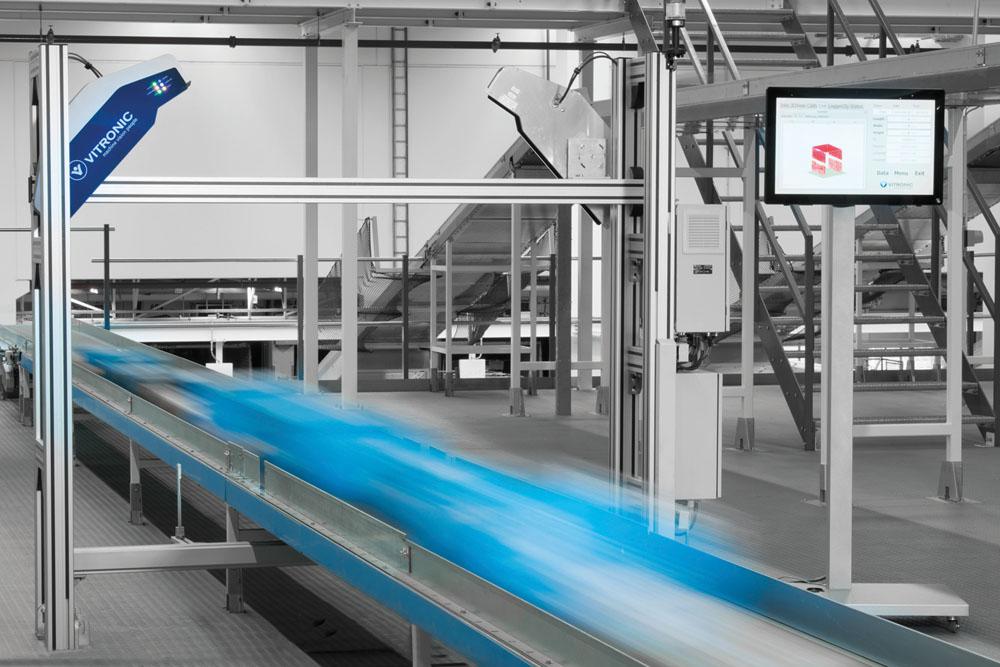

At the 26th European Photovoltaic Solar Energy Conference and Exhibition from September 5 - 9, 2011 in Hamburg/Germany, VITRONIC is presenting camera-based inspection systems for the quality control of solar cells, wafers and modules. This allows the implementation of customized solutions for complex challenges and specific requirements.VITRONIC is a leading supplier of camera-based inline inspection systems for photovoltaics, with almost 1,000 VINSPECsolar systems installed for 40 customers around the world. VINSPECsolar solutions are not only suitable for carrying out standard tasks in the quality control of solar cells, wafers and modules efficiently and safely, but also for complex inspection processes, sophisticated system integrations and flexible upgrades, where other systems struggle.

With their high-resolution camera technology, VINSPECsolar systems reliably recognize defects including micro cracks, inclusions, holes, corner and edge breakage, as well as grid line interruptions, paste marks and color deviations. They ensure that variations in quality are quickly recognized so that the product quality can be kept at a consistently high level. Tried-and-tested intelligent classification software makes it possible to sort reliably by color class, A and B quality or rejection rate.

In addition, VINSPECsolar solutions allow valuable data to be collected during quality control in order to optimize processes - for example by recognizing deviations in the production process or improving the integration of modified processes.

The particular flexibility of the inspection system is also shown by the fact that more than 100 of the current generation of solar cell types have been calibrated and this information is being used by a range of customers on a daily basis - a tremendous challenge in light of the significant differences between different solar cells, for example in terms of print layout and surface texture.

Additional information on VITRONIC VINSPECsolar systems in photovoltaics can be found here: http://www.vitronic.de/en/industry/photovoltaic/

Visit VITRONIC at the EU PVSEC from September 5 - 9, 2011 in Hamburg: Hall 3, Booth B1U

Since 1984, machine vision expert VITRONIC in Wiesbaden has been supplying standard products with customer-specific up-gradeable modules all the way to customized special solutions. These are developed, manufactured and sold by VITRONIC themselves. This way, customers receive turn-key systems from one supplier - from hardware to software. VITRONIC is one of the world's leading machine vision companies. VITRONIC had more than 340 employees in 2010.

VITRONIC Dr.-Ing. Stein

Bildverarbeitungssysteme GmbH

Hasengartenstr. 14

65189 Wiesbaden, Germany

www.vitronic.com

Tel: +49 (0)611–7152-0

Fax: +49 (0)611–7152-133

Press contact: Lucas Goebel

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Vitronic presents standard systems and customized solutions at EU PVSEC 2011 here

News-ID: 182618 • Views: …

More Releases from VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH

Automatic Weld Seam Inspection VIRO WSI with a New Sensor: More Compact – Fast …

Wiesbaden, April 24, 2019 – For over two decades, VITRONIC’s automated weld seam inspection system VIRO WSI has been successfully used by the automotive industry and its suppliers. With newly developed sensors, the inspection system is now faster and more compact than its predecessor and is optimized for MIG/MAG as well as laser seams. Thereby, the inspection system of the technology leader VITRONIC is ideally suited for all…

VITRONIC GmbH and TNT Nederland BV announce global partnership

VITRONIC delivers state-of-the art technology with identification and measurement applications throughout the TNT Nederland BV (TNT) service chain

VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GmbH and TNT have entered into a long-term global partnership to equip hubs, gateways and service centers with the latest machine vision technology for data capture of all transported items. The initial project, which covers over 100 sites throughout Europe, consists of systems that read barcodes, measure the volume…

Automated 3D Volume Measurement and Defect Detection

Every millimeter counts: VOLUMEChd measures the volume of any moving object in the field of intralogistics.

The new VOLUMEChd 3D volume measurement system from VITRONIC precisely measures rectangular and irregularly shaped objects in the field of intralogistics and reliably detects defects on boxes. This makes it possible, for example, to automate invoicing, optimize the utilization of transport fleets and avoid warehouse technology malfunctions.

Developed by VITRONIC, the VOLUMEChd 3D volume measurement system…

Automatic barcode reading with SAP connection

Automatic barcode reading with SAP connection

Seamless logistics processes – VITRONIC and SMILOG offer a complete system for barcode reading and data integration in SAP applications.

VICAMsnap! camera systems from VITRONIC are used for automatic data capture, for example, in material flow management and warehousing, in goods receipt processes, by post and parcel services and in the retail trade. Together with logistics expert SMILOG, VITRONIC now offers a complete solution for automatic…