Press release

Pharmaceutical leaflets - More output by multiple up production

Kupferzell, 25.03.2011:With the model pharmaline S Maximum Machines UG provides machinery to improve output, quality and efficiency in a tremendous way by running a multiple up production.

In many companies the production of pharmaceutical leaflets with just a single fold is done by the traditional method printing – cutting – folding – packaging in a one up production. There is a lot of manual work to finish the products and getting an even package of 500 single folded leaflets. One operator is able to manufacture approx. 6.000 sheet per hour.

The pharmaline S allows in combination with a fitting folding machine an effective multiple up production. Based on the correct sheet size in printing there is no external cutting but in the folding machine the cut and splitting of the products is done effectively in an inline process. With formats like 148x210mm and 148x297mm a four up production in possible. In this case one operator cannot cover the produced volume without the right delivery.

Using the pharmaline S the operator is able to cover up to 8.000 cycles which means up to 24.000 products per hour in a three up production. All products get shingled, pressed and counted. The machine provides even and flat products, easy to stack and doing the final packaging without a lot of manual work. The efficiency is up to 400% of the initial output with just one operator. The machine requires less space. The quality of the products is proven in the final packaging process with significant less stops in continuous operation.

The setup time of the machines is short. They are controlled by plc. All inputs are set at the display. Just the belting has to be set by hand. The operator is informed about errors, jams, open covers and others.

The company Maximum Machines UG was founded in summer 2009 and is located in Kupferzell, Germany. Major activities are special designed machines for postpress like pressing units, stackers, deliveries. They are supplied to OEM customers, to dealers worldwide and to direct customers in Europe with a focus on pharmaceutical print industry.

Press release and any informations:

Achim Bauer

Geschäftsführer

Maximum Machines UG

Telefon 07944 599 168

Telefax 07944 599 170

eMail: achim.bauer@maximum-machines.com

Alte Haller Straße 14

74635 Kupferzell

Germany

http://www.maximum-machines.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pharmaceutical leaflets - More output by multiple up production here

News-ID: 168471 • Views: …

More Releases from Maximum Machines

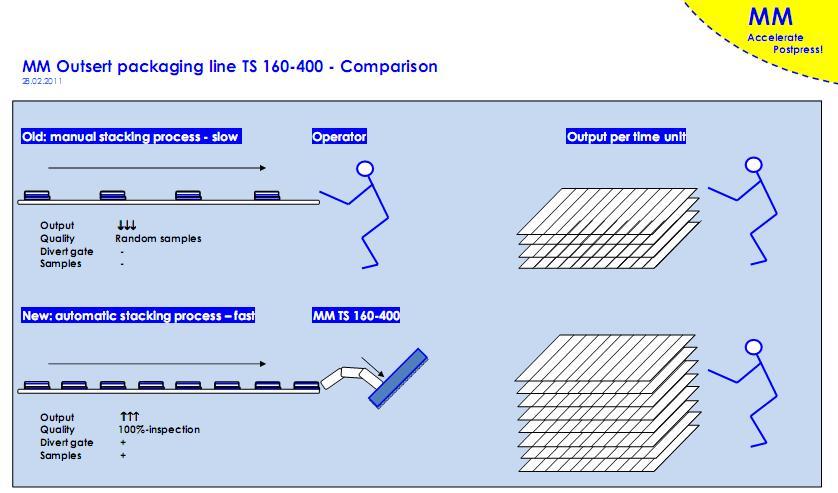

Outserts – Economic inspection and packaging

Kupferzell, 13.04.2011:

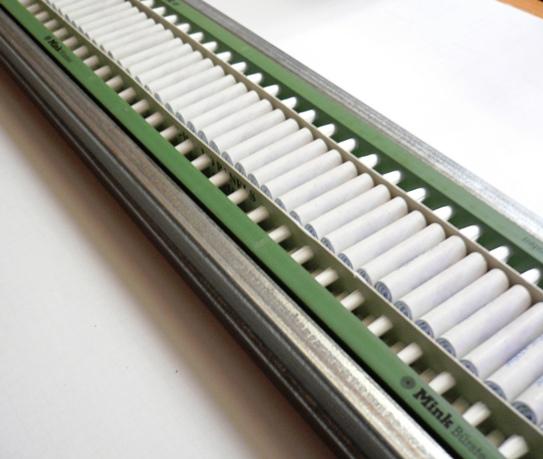

With the model TS 160-400 Maximum Machines UG offers a machine for most economic checking and packaging of pharmaceutical leaflets like outserts in a contninuous process. The customers are printing companies for pharmaceutical leaflets all over the world. The products are folded many times and closed with glue or labels. Outserts are small folded leaflets with a format range of 1“x1“ (25x25mm) up to 4“x6“ (100x150mm). The product…

Inline outsert packaging line TS 160-400

Kupferzell, 09.02.2011:

In January 2011 Maximum Machines UG presented a new designed packaging line for folded and glued outserts in cardboard trays. It is the first machine in the world running fully automatic with this kind of products. The customers are printing companies who are producing pharmaceutical leaflets with a paper weight between 38 and 60 g/m². The so called outserts are an extreme challenge. Out of a single sheet…

New vertical stacker PSV 600

In December 2010 Maximum Machines UG delivered for the first time two pressing units with vertical delivery model PSV 600, equipped with PLC as a standard. Beside the infeed section equipped with segments for easier adjustment and a fast pneumatic batch counter also the new pressing unit, strengthened up for about 30% and already used in the models PU, PSH and PSS is integrated. Result: faster and better is still…

More Releases for Kupferzell

Battery Energy Storage Systems market, worth USD 20.4 billion in 2022, is projec …

The global battery energy storage systems (BESS) market is set to expand significantly over the forecast period, driven by the rising investments in renewable energy projects, the increasing deployment of grid energy storage solutions, and a growing need to enhance grid stability and efficiency. Valued at US$ 20.4 Bn in 2022, the market is expected to grow at a compound annual growth rate (CAGR) of 12.7% from 2023 to 2031,…

Global Battery Energy Storage Systems Market Projected to Hit USD 59.6 Billion b …

The global battery energy storage systems (BESS) market(https://www.transparencymarketresearch.com/battery-energy-storage-system-market.html) is set to expand significantly over the forecast period, driven by the rising investments in renewable energy projects, the increasing deployment of grid energy storage solutions, and a growing need to enhance grid stability and efficiency. Valued at US$ 20.4 Bn in 2022, the market is expected to grow at a compound annual growth rate (CAGR) of 12.7% from 2023 to 2031,…

Battery Energy Storage Systems Industry valued at USD 20.4 Billion in 2022; proj …

The global battery energy storage systems (BESS) market(https://www.transparencymarketresearch.com/battery-energy-storage-system-market.html) is set to expand significantly over the forecast period, driven by the rising investments in renewable energy projects, the increasing deployment of grid energy storage solutions, and a growing need to enhance grid stability and efficiency. Valued at US$ 20.4 Bn in 2022, the market is expected to grow at a compound annual growth rate (CAGR) of 12.7% from 2023 to 2031,…

Battery Energy Storage Systems Industry Valued at USD 20.4 Billion in 2022, Proj …

The global battery energy storage systems (BESS) market(https://www.transparencymarketresearch.com/battery-energy-storage-system-market.html) is set to expand significantly over the forecast period, driven by the rising investments in renewable energy projects, the increasing deployment of grid energy storage solutions, and a growing need to enhance grid stability and efficiency. Valued at US$ 20.4 Bn in 2022, the market is expected to grow at a compound annual growth rate (CAGR) of 12.7% from 2023 to 2031,…

Outserts – Economic inspection and packaging

Kupferzell, 13.04.2011:

With the model TS 160-400 Maximum Machines UG offers a machine for most economic checking and packaging of pharmaceutical leaflets like outserts in a contninuous process. The customers are printing companies for pharmaceutical leaflets all over the world. The products are folded many times and closed with glue or labels. Outserts are small folded leaflets with a format range of 1“x1“ (25x25mm) up to 4“x6“ (100x150mm). The product…

Inline outsert packaging line TS 160-400

Kupferzell, 09.02.2011:

In January 2011 Maximum Machines UG presented a new designed packaging line for folded and glued outserts in cardboard trays. It is the first machine in the world running fully automatic with this kind of products. The customers are printing companies who are producing pharmaceutical leaflets with a paper weight between 38 and 60 g/m². The so called outserts are an extreme challenge. Out of a single sheet…