Press release

New vertical stacker PSV 600

In December 2010 Maximum Machines UG delivered for the first time two pressing units with vertical delivery model PSV 600, equipped with PLC as a standard. Beside the infeed section equipped with segments for easier adjustment and a fast pneumatic batch counter also the new pressing unit, strengthened up for about 30% and already used in the models PU, PSH and PSS is integrated. Result: faster and better is still achievable!The pressing station with vertical delivery PSV 600 for two ups which handles smallest formats due to its belt-distance of 80mm is equipped with driven table-belts switched by an electric coupling. This electric coupling is exactly controlled by the PLC depending on the thickness and the number of the incoming products. This improves the forming of stacks and reduces the tendency for marks on the product because the dynamic pressure inside the stack on the delivery table can be controlled automatically for the first time.

Additionally it is possible to set-up the machine shortly due to the automatic shingle stream control. This automatic shingling guarantees a reliable production without later needs of correction of speed parameters. If the speed or the cadence of the folding machine is changing, the shingle length rests constant. The operator can concentrate completely on the folding machine. An integrated emptying cycle assists in the end of production to run out the products remaining in the machine completely and sets also the production order counter to zero. A shift counter can be set manually, an additional counter counts all produced products.

Due to its line display the used PLC allows the precise indication of i.e. faults like information about jams on different positions, open security doors etc. Therefore the operator can locate the cause of the jams quicker and can correct it in a shorter time. More indications inform about i.e. necessary maintenance as a function of machine operation time. All these informations make sure that no needless maintenance are done, if the operation time of the machine in the past period was lower as expected but also indicates an earlier maintenance if the operation time of the machine was higher than expected. Keeping the machine in a better condition and adjust the cost for maintenance to the real requirements is the result.

Together all improvements result in a delivery which set new standards in its category and all for a unique attractive price! The new operating interface is used in series in all pressing units and deliveries from Maximum Machines. Currently additional improvements like controlling of the length and measured distance of the feed sheets are in test phase. With this, problems in the folding machine can be identified and registered. As result the operator can improve the quality of the products and increase the productivity by optimized adjustment of the folding machine.

Company portrait:

The company Maximum Machines UG domiciled in Kupferzell, Germany, was founded in summer 2009 and is concerned with machinery for print finishing and bookbinderies, especially with pressing units, deliveries and stackers. Our customers are famous manufacturers of folding machines, domestic representatives and foreign distributors all over the world as well as direct customers in Germany and in the European countries.

Press contact and further information:

Achim Bauer

Managing Director

Maximum Machines UG

Phone +49 7944 599 168

Fax +49 7944 599 170

eMail: achim.bauer@maximum-machines.com

Alte Haller Straße 14

74635 Kupferzell

http://www.maximum-machines.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New vertical stacker PSV 600 here

News-ID: 160959 • Views: …

More Releases from Maximum Machines

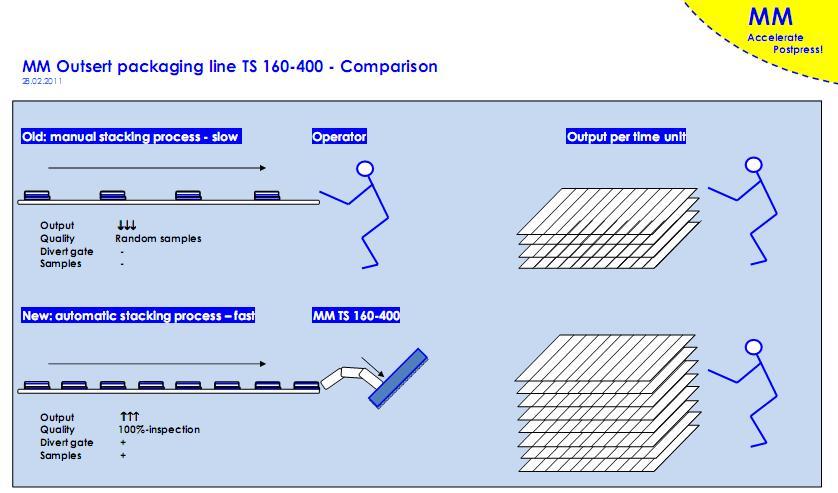

Outserts – Economic inspection and packaging

Kupferzell, 13.04.2011:

With the model TS 160-400 Maximum Machines UG offers a machine for most economic checking and packaging of pharmaceutical leaflets like outserts in a contninuous process. The customers are printing companies for pharmaceutical leaflets all over the world. The products are folded many times and closed with glue or labels. Outserts are small folded leaflets with a format range of 1“x1“ (25x25mm) up to 4“x6“ (100x150mm). The product…

Pharmaceutical leaflets - More output by multiple up production

Kupferzell, 25.03.2011:

With the model pharmaline S Maximum Machines UG provides machinery to improve output, quality and efficiency in a tremendous way by running a multiple up production.

In many companies the production of pharmaceutical leaflets with just a single fold is done by the traditional method printing – cutting – folding – packaging in a one up production. There is a lot of manual work to finish the products and getting…

Inline outsert packaging line TS 160-400

Kupferzell, 09.02.2011:

In January 2011 Maximum Machines UG presented a new designed packaging line for folded and glued outserts in cardboard trays. It is the first machine in the world running fully automatic with this kind of products. The customers are printing companies who are producing pharmaceutical leaflets with a paper weight between 38 and 60 g/m². The so called outserts are an extreme challenge. Out of a single sheet…

More Releases for PSV

Platform Supply Vessels Psv Market Size Analysis by Application, Type, and Regio …

According to Market Research Intellect, the global Platform Supply Vessels Psv market under the Aerospace and Defense category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The market for platform supply vessels (PSVs) is expanding steadily due to a rise in offshore rig…

Hybrid Platform Supply Vessels (PSV) Market Size,Volume,Revenue Trends Analysis …

Global Info Research announces the release of the report "Global Hybrid Platform Supply Vessels (PSV) Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across…

Global Band Saw Machine Market Size 2017 Brother Industrial Sewing Maschines, Da …

Band Saw Machine

A market study ” Global Band Saw Machine Market ” examines the performance of the Band Saw Machine market Size 2017. It encloses an in-depth Research of the Band Saw Machine market state and the competitive landscape globally. This report analyzes the potential of Band Saw Machine market in the present and the future prospects from various angles in detail.

The Global Band Saw Machine Market 2017 report includes…

Global Meat Mincers Market 2017 - Maschinenfabrik Seydelmann, Dadaux SAS, Groupe …

Meat Mincers Market Research Report

A market study based on the "Meat Mincers Market" across the globe, recently added to the repository of Market Research, is titled ‘Global Meat Mincers Market 2017’. The research report analyses the historical as well as present performance of the worldwide Meat Mincers industry, and makes predictions on the future status of Meat Mincers market on the basis of this analysis.

Request For Sample Copy of…

Canada Platform Supply Vessels PSV Offshore Support Vessel Industry 2016 Market …

MarketResearchReports.Biz presents this most up-to-date research on "Canada Platform Supply Vessels PSV Offshore Support Vessel Industry 2016 Market Research Report"

Description

The Canada Platform Supply Vessels PSV Offshore Support Vessel Industry 2016 Market Research Report is a professional and in-depth study on the current state of the Platform Supply Vessels PSV Offshore Support Vessel industry.

The report provides a basic overview of the industry including definitions, classifications, applications and industry chain structure. The…

Global Platform Supply Vessels PSV Offshore Support Vessel Consumption 2016 Mark …

Summary

The Global Platform Supply Vessels PSV Offshore Support Vessel Consumption 2016 Market Research Report is a professional and in-depth study on the current state of the Platform Supply Vessels PSV Offshore Support Vessel market.

First, the report provides a basic overview of the Platform Supply Vessels PSV Offshore Support Vessel industry including definitions, classifications, applications and industry chain structure. And development policies and plans are discussed as well as manufacturing processes…