Press release

Improve quality control with apps for your digital microscope

Finding the right equipment for quality control can be time consuming. That’s why it is important to find long lasting and agile equipment. One solution is a digital microscope with quality control improving apps that allows the operator to alter the system to meet future requirements without investing in new equipment.With a digital microscope from TAGARNO, the user can purchase apps specifically developed to improve quality control processes for their microscope. This gives the operator access to the latest technology without having to invest in new microscopes all the time.

A wide range of add-on features

Among the apps developed by TAGARNO are:

Image Comparison that allows the operator to compare a reference image of a golden sample with a recent sample from the production line;

Focus Stacking that stacks images taken at different focus heights to create one ultra-sharp image with no blurred or out of focus areas;

TAGARNO Measurement application that enables the operator to perform on-screen measurements and add annotations and text to the image directly on the microscope;

Watermark that allows the user to brand an image with a logo or confidential text. It is also possible to add date, time, field of view plus microscope name and serial number as an imprint on the image;

Verification Lines that enables the operator to quality check an object by placing accurately calibrated vertical and/or horizontal lines as a layer on top of it.

Capture and share images for improved collaboration

With a digital microscope, you can easily capture and share images of your work - both with and without graphics on. The shared documentation material allows for improved collaboration with all supply chain partners and more efficient quality control.

Caption: ”With apps for your digital microscope, you don’t have to purchase new quality control equipment once your processes and requirements change.”

About TAGARNO

TAGARNO's digital microscopes are used for visual inspection and quality control in a variety of industries worldwide. The user-friendly add-on apps enable the operator to customize their digital microscope and update it as needed to fit ever-changing quality control requirements.

Read more about TAGARNO at www.tagarno.com

TAGARNO A/S | Sandøvej 4 | 8700 Horsens | Denmark

Contact TAGARNO Sales and Marketing Coordinator Gitte Engkjær

ge@tagarno.com / +45 76251124

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Improve quality control with apps for your digital microscope here

News-ID: 1530581 • Views: …

More Releases from ins trade media service

Bio-Gate concludes another cooperation agreement with leading multinational impl …

Medical technology business further strengthened

Coating of orthopaedic revision implants with HyProtect technology

Focus on protection against infections with multi-resistant germs

Nuremberg/Bremen, 5 July 2022 - Bio-Gate AG (ISIN DE000BGAG981), a leading provider in the field of innovative health technologies, has concluded a contract with a leading multinational medical device manufacturer for the coating of orthopaedic implants in human medicine. As part of the cooperation and the joint project management, Bio-Gate is responsible…

Walki introduces a broad portfolio of recyclable materials for the growing froze …

Walki is answering to the growing demand for frozen food by expanding its portfolio of recyclable materials.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

"Frozen food is an ideal way to prolong shelf life without losing out on the vitamins. It is also an excellent way…

Dassiet and OrthoPets collaborate to provide safer and easier orthopedic care fo …

The teams combine Dassiet’s clinically proven medical and material innovations with OrthoPets' strong experience in custom pet orthoses to provide human level care for animals.

The material innovation company Dassiet, and the leading, US based pet orthosis manufacturer OrthoPets have started collaboration to create sustainable, safe and user-friendly pet healthcare products. Both companies want to first tackle the issues surrounding veterinary casting, splints, and bandages, and to provide vets, pets and…

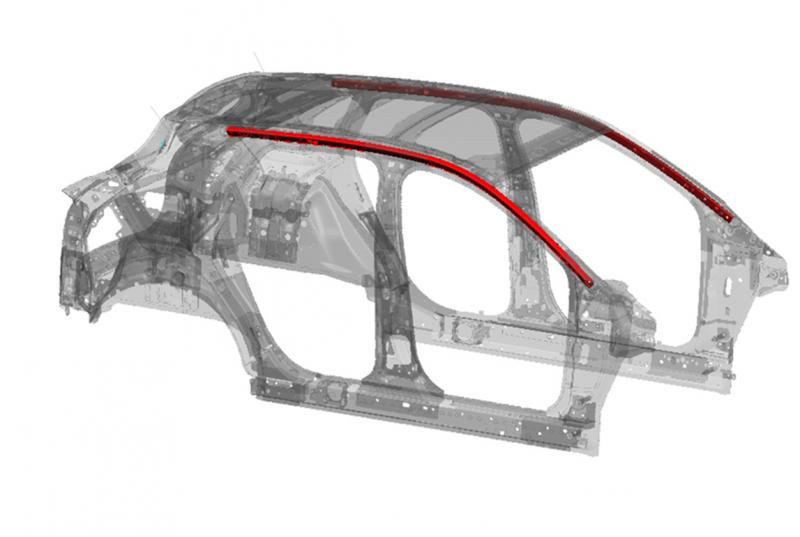

Shape Corp. wins Swedish Steel Prize 2019

The winner of the 20th international Swedish Steel Prize is Shape Corp. from the United States. The prize is awarded for the groundbreaking use of martensitic steel in a 3D formed tube for automotive roof rail applications.

“With great skill, Shape Corp. has shown the way forward and has succeeded in efficiently utilizing a modern material with the highest possible strength level. This shows a major opportunity in challenging other lightweight…

More Releases for TAGARNO

Digital Microscope Market Forecasts (2020-2026) Segmentation By Top Manufacturer …

The global Digital MicroscopeMarket is projected to grow with a striking growth rate of 2.74 % over the forecast period 2020-2026, divulges the latest research report presented by Big Market Research. The report represents a basic overview of the market status, competitor segment with a basic introduction of key vendors, top regions, product types and end industries. This report gives a historical overview of the market trends, growth, revenue, capacity,…

Digital Microscopes Market Forecast till 2026: Olympus Corporation, Nikon Corpor …

A research team at University of Houston, U.S., developed a multicolor fluorescence microscope from a smartphone and a 3-D printer in December 2017. Moreover, researchers at the University of Waterloo in Ontario, developed a low-cost and lens free field-microscope in June 2017, by incorporating artificial intelligence and mathematics models of light to develop 3-D images. Grundium OY — Finland-based manufacturer of multi-camera technology — received an investment of US$ 2.3…

Inspect large PCBs in ergonomically correct working positions

TAGARNO is now announcing a modified digital microscope solution, promoting ergonomically correct working conditions and new possibilities to inspect large PCBs with plenty of work space beneath the camera.

By incorporating a new lens and flex arm, compatible with the TAGARNO FHD ZAP digital microscope solution, the user is now able to be positioned directly in front of the camera, in an optimal working posture due to the placement of…

Prevent quality issues by zooming in on printed circuit boards

Preventing mistakes or defects in manufactured products and avoiding problems when delivering solutions or services to customers are natural concerns to EMS providers. Digital microscopes integrated as part of the Quality Assurance in production and R&D departments can often play an important role to clear these concerns.

When inspecting bare solder boards, connectors or other components, digital microscopes allows the operator to zoom in on the product to either proof…

Automatically count speck and bran in any type of flour

A new way of counting speck and bran in flour samples is paving the way for more efficient and accurate milling processes

There is now a new, accurate and digital way to count the number of speck and bran in flour samples as an alternative to the strenuous manually estimation of the quality levels. The aim is to ensure high quality in the flour production and guarantee efficiency and…

Improve quality control processes using a digital microscope

Inspection of assembled boards, connectors or other SMT components

In the electronics quality control (QC) process by which entities review the quality of all factors involved in production, a visual product inspection is often performed. Here, every product is examined visually, often using a microscope due to the miniaturization before the product is sold into the external market.

Inspectors will be provided with lists and descriptions of unacceptable…