Press release

Steel Reinforcement Specialist Launches Friction Welded Coupler

The HT Welded Coupler for re-bar is based on technology widely used in aerospace and automotive industries.

“In the past, to create a coupled joint, both bars have to be threaded – one end receiving a coupler in the factory, the other end being positioned and screwed-in on-site. Our system requires no threading. We friction weld the couplers to the re-bar in the factory so they are simply screwed together on site in one quick and efficient process. You don’t even need a torque wrench.” commented Hy-Ten director Richard Webster.

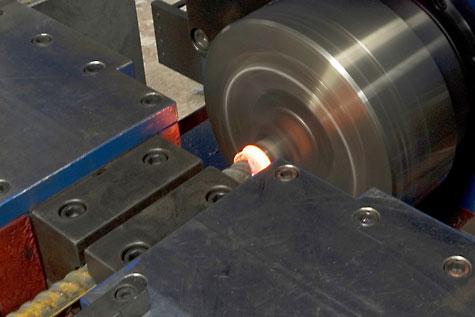

Hy-Ten has invested a substantial sum in researching, perfecting and setting up the new process. Using a dedicated machine, couplers are rotated at high speed. The re-bar is offered up to the coupler and the friction between the surfaces scours and heats the metal surfaces to fusing point.

Extensive trials by the Certification Authority for Reinforcing Steel (CARES) have proven the strength of the union after testing multiple samples to destruction. Ultimate failure was in the re-bar and not the joint, with forces as high as 630 Newton’s being applied to break the bar. The CARES technical approval certificate can be seen at www.ukcares.com/TAPDF/5031.pdf.

Hy-Ten has already tested and obtained approval for bar diameters from 16 to 40mm with tests on 50mm bar pending. The company began offering the new system in August and has already noted strong interest from construction contractors and consultants. “Productivity improvement and significant cost saving are driving contractor interest,” commented Richard Webster. “Importantly, the material savings make this system a more economic alternative for 25mm bars and larger, as the friction welded joint is cheaper than the corresponding lap length,” he concluded.

More Information

High resolution images on the web at www.ainsmag.co.uk/hy246/4802hy1a-welded-coupler.htm

Information on Friction Welding

Friction welding (FW) is a solid state welding process that uses mechanical interaction between components and a lateral force to generate localised heat to weld them together. During the localised heating there is some displacement of plasticised material, but no actual melt of metal occurs. Technically therefore the process is not welding but forging.

Material can be joined in a fraction of the time required compared to tradition gas or arc welding. Moreover, because heating and plasticisation is extremely localised and there is no actual melt the metallurgical properties of the materials remain largely unaffected and their inherent strength is maintained.

Friction welded couplings are widely used in high rise buildings in areas of the world subject to earthquake. Applications in aerospace involve the jointing of dissimilar metals in components, copper and aluminium for example. In car manufacture the valve heads and stems in pushrods are commonly jointed this way.

Bamtec is a system of steel reinforcement for flat concrete slabs developed in Germany. Hy-Ten, one of the UK’s major reinforcement manufacturers, is the exclusive supplier of Bamtec in the UK and Ireland. The system gives significant savings in steel, manpower and time, allowing contracts to proceed more efficiently.

Richard Webster, Director, Tel. +44 (0)151 525 1745 Fax. +44 (0)151 523 2252

Hy-Ten Ltd, Bridle Road, Bootle, Merseyside, L30 4UG, UK

E-mail: rkw@hy-ten.co.uk Web: www.hy-ten.co.uk

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Steel Reinforcement Specialist Launches Friction Welded Coupler here

News-ID: 152927 • Views: …

More Releases from Hy-Ten Ltd

Bamtec Roll-Out Concrete Reinforcement Speeds Completion of Biosciences Incubato …

The Stevenage Biosciences Catalyst has got off to a flying start with the aid of Hy-Ten’s innovative Bamtec concrete reinforcement system. Floor plates on the 9000 square metre campus were constructed more quickly and with less reinforcement material than by conventional methods. Moreover, the new building has lower embedded energy and CO2, less labour was required and rebar fixers were able to complete the task with less strain…

Positional Couplers From Hy-Ten Extends Frictional Welded Coupler Ranges for Con …

Hy-Ten, a pioneer in the UK in the use of friction welded coupler technology for structural reinforcement of concrete, has extended the technique to embrace a new positional coupler range. Fully tested and certified by CARES, the certification authority for reinforcement steels, the couplers are available now.

Director Richard Webster commented, “Friction welded couplers were added to our range just 12 months ago. Engineers and contractors have enthusiastically…

Largest Concrete Frame Building Completed On-Time With Bamtec Prefabricated Stee …

One of the largest concrete frame structures in the UK, the Forth Valley Royal Hospital, was completed on time with the aid of Bamtec, an off-site fabricated steel carpet of floor slab reinforcement. Bamtec is manufactured exclusively by steel reinforcement specialist Hy-Ten in the UK. The use of this reinforcement system also significantly reduced the steel required and in direct consequence the carbon footprint of the project.

The construction…

Prefabricated Roll-Out Steel Reinforcement for Luton Academies Construction

Barnfield South Academy and Barnfield West Academy in Luton have been completed and handed over on time, thanks in part to the use of Hy-Ten’s rollout steel reinforcement system, Bamtec. This has been used for concrete floor construction enabling main contractor Wates Construction to keep on-track despite dreadful weather.

Wates Construction decided to adopt the Bamtec system for concrete floor reinforcement to make time in the schedule. Academies…

More Releases for Welded

How to choose Seamless Pipe vs Welded Pipe vs Spiral Welded Pipe

Seamless pipe, welded pipe, and spiral welded pipe are the three most common types. They may appear similar in appearance, but the differences are profound in essence, with the core distinction indeed stemming from manufacturing processes.

Comparison Table

FEATURE DIMENSION

SEAMLESS STEEL PIPE

LONGITUDINALLY WELDED PIPE

SPIRAL WELDED PIPE

Manufacturing Process

Solid billet piercing and rolling, no weld seam.

Steel plate/sheet is curved and welded along a longitudinal straight seam.

Steel strip is coiled at a spiral angle, forming…

Welded Parts Applications & Manufacturing

Welded parts [https://www.simis-manufacturer.com/products/], with their reliable connection performance and structural strength, are widely used in various industries.

In the mechanical manufacturing industry, it is often used in the manufacturing of core components such as machine tool beds, construction machinery frames, and pressure vessels. Through welding, multiple metal components are connected into a whole to meet the equipment's requirements for structural stability and load-bearing capacity. For example, the boom of an excavator…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is experiencing notable growth due to increased demand for high-performance components in industries requiring…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is witnessing steady growth due to the rising demand for precision-engineered components in high-performance…

Welded Bellows Market Size Analysis by Application, Type, and Region: Forecast t …

According to Market Research Intellect, the global Welded Bellows market under the Internet, Communication and Technology category is expected to register notable growth from 2025 to 2032. Key drivers such as advancing technologies, changing consumer behavior, and evolving market dynamics are poised to shape the trajectory of this market throughout the forecast period.

The welded bellows market is experiencing steady growth due to increasing demand across high-precision industries such as aerospace,…

Carbon welded steel pipe factory

LSAW Carbon Steel Pipe

Pipe Type:LSAW Steel Pipe,Longitudinally Submerged Arc Welding Pipe ,DSAW Steel Pipe,Welded Steel Pipe

Specification: Outside Diameter:355.6mm-2320mm

Wall Thickness:5.0mm-60mm

…