Press release

JAKOB Antriebstechnik is presenting its new transfer rail couplings at this year's EuroBlech expo

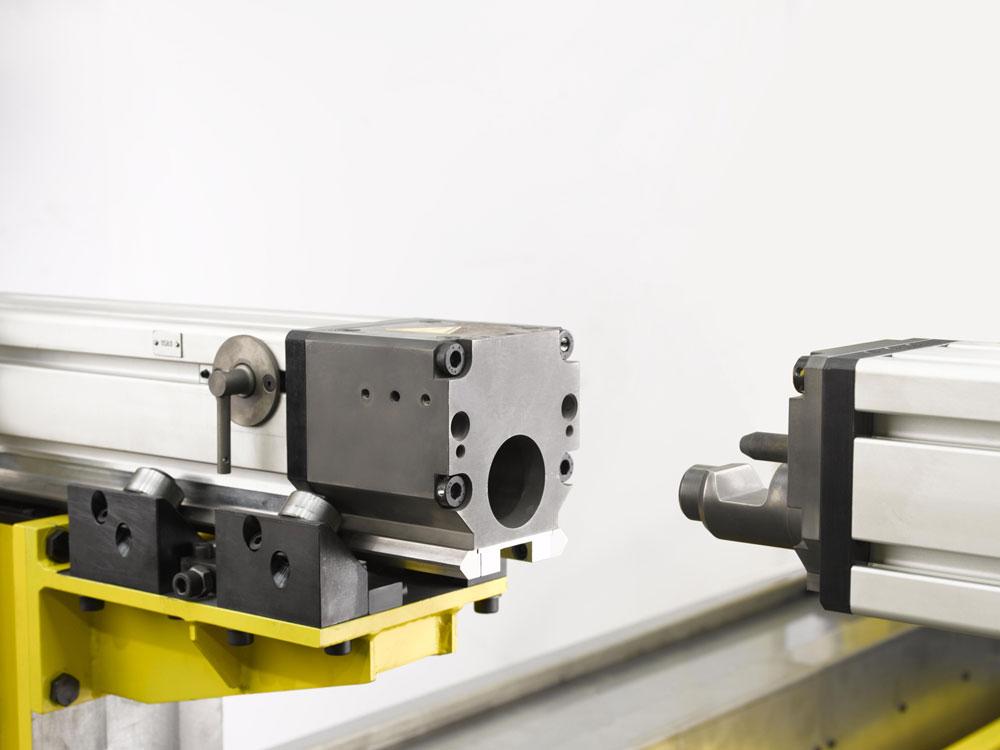

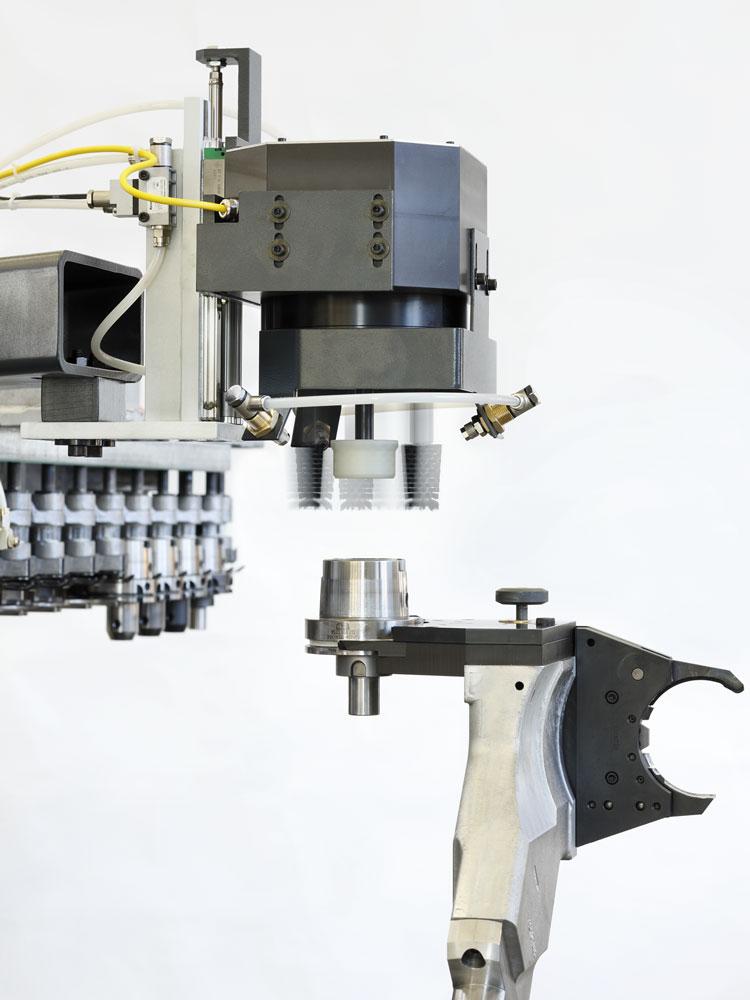

Increased performance thanks to automated set-up processes: due to the large number of different products, modern pressing plants nowadays - more than ever - face the challenge of making tool changes and setting-up processes of systems go off without a hitch. With regard to productivity, it goes without saying that set-up times play an essential role. State-of-the-art transfer rail couplings can contribute to increasing the economic efficiency and safety of the systems. Right on time for this year's International Sheet Metal Working Technology Exhibition 'EuroBlech' in Hanover, Germany, the inventor of the metal bellow coupling - JAKOB Antriebstechnik GmbH - is presenting its trailblazing new development: the pneumatic transfer rail coupling GKZ!'Modern couplings have to meet a large number of different demands', explains Dr. Ing. Arno Wörn, engineer at JAKOB Antriebstechnik. 'First of all, they have to be light but at the same time extremely rigid as well as self-locking during the clamping process.' On top of that, they have to be monitored electrically and operation should be intuitive. Former systems used to opt for a hydraulic or electro-mechanic clamping solution. 'But especially in the event of retrofitting, these versions have adverse effects on economic efficiency', Dr. Wörn points out. As a general rule, it is advisable to use elements which are already available in the system to operate the automatic couplings. 'The hydraulic concept used to result in costly and complex maintenance needs.' After all, additional pumps and supply lines have to be installed. 'On the whole this solution costs a pretty penny.'

The scenario is quite different when electric motors are employed to operate the couplings. The electric drive adds a lot of weight to the coupling. 'The dependence on power becomes a problem during a blackout, though', explains the engineer. 'Due to the high gear ratio, releasing the coupling is difficult then.' Transfer rail couplings manufactured by JAKOB Antriebstechnik evade these disadvantages and thus guarantee highly dynamic transport and precise exchange of tools. The innovative systems are available for axial and vertical set-ups.

The transfer rail couplings type GKZ can be adapted to fit all current transfer rail profiles. Besides the automatic pneumatic coupling system, the portfolio includes a manually operated version as well. The latter is usually secured by a screw. 'The couplings close gaps of up to five millimetres between the active and the passive component automatically', confirms Dr. Wörn. The couplings are scanned electrically and mounted on the transfer rails directly or on a regular adapter plate. In addition, the automatic systems can be equipped with energy couplings. 'Upon locking, they establish the electric and pneumatic connection with the transfer rail.' The advantages are obvious: the pneumatic solution type GKZ is light-weight and not affected by power blackouts - just like a hydraulic system. At the same time, it is a low-maintenance solution with an economic efficiency comparable to couplings with an electric drive. In operation, the transfer rail couplings reduce set-up times and thus increase the productivity of the entire system:

Interested visitors of the EuroBlech 2010 in Hanover are invited to drop in at the booth of JAKOB Antriebstechnik in hall 27, booth E52 to get in-detail information on the new transfer rail couplings.

About JAKOB GROUP:

JAKOB GROUP unites seven medium-sized companies from the driving, clamping, and automation technology as well as from the innovative fields of vacuum, ionic, and plasma technology under its umbrella. The individual companies work independently but feel obliged to cooperate closely. Thanks to this philosophy, customers can profit from multiple synergies.

About JAKOB Antriebstechnik:

For almost 40 years JAKOB Antriebstechnik GmbH has been one of the leading manufacturers of servo and safety couplings. Mechanical clamping elements with an internal force amplifying system are part of the portfolio, too. Thanks to intelligent design, trailblazing technology, and tailor-made solutions, JAKOB Antriebstechnik is estimated and recommended as a reliable partner by customers in Germany as well as abroad.

Contact within the company

JAKOB Antriebstechnik GmbH

JAKOB Antriebstechnik GmbH

Daimler Ring 42 | 63839 Kleinwallstadt | Germany

Phone +49 (0)6022 - 2208 0

info(at)jakobantriebstechnik.de

http://www.jakobantriebstechnik.de

Press contact

knoefler-journalist . media + communications GmbH

Nordring 53-55 | 63843 Niedernberg | Germany

Benjamin Knöfler, Ayenegbe Stephen

Phone +49 (0)6028 - 80729 0

jakob(at)kj-media.com

http://www.knoefler-journalist.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release JAKOB Antriebstechnik is presenting its new transfer rail couplings at this year's EuroBlech expo here

News-ID: 148670 • Views: …

More Releases from JAKOB GRUPPE

Clean clamping solution: tool taper cleaning device by T+S-JAKOB

One of the most important criteria when expecting the treatment of work pieces in state-of-the-art milling machines to go off without a hitch is keeping the tool clamping force at a steady level despite changing tools. Even with properly shielded tool magazines and changers, it is almost impossible to avoid dirt - such as chips or cooling lubricant from the processing chamber - settling on the tool taper. In order…

Focussing power with the new machine vice CENTRO Gripp

Drilling, milling, grinding - when machine processing material, it always comes down to one essential aspect: precision. It goes without saying that the clamping element is of major importance for consistent results. The ALLMATIC-Jakob Spannsysteme GmbH is now presenting its solution boasting extraordinary durability and highest precision. Thanks to the tried and tested 'grip system' developed by the company, clamping unfinished parts as well as already treated workpieces of different…

Superfinish surfaces thanks to trail-blazing clamping technology

Actually, it is not exactly easy to improve a good product. Sometimes it is the small details that make a profound difference. Georg Forster, certified engineer at Supfina Grieshaber GmbH & Co. KG from Wolfach in German Baden-Wuerttemberg, says he knows that from prior experience as well. He is one of the 20 design engineers who develop and improve the systems used for surface treatment and the special Supfina 'superfinishing'…

More Releases for Antriebstechnik

Plastic Rack and Pinion Market Booming Worldwide from 2024 to 2031 |Molinati, Lo …

The Plastic Rack and Pinion Market Trends Overview 2024-2031:

A new Report by Worldwide Market Reports, titled "Plastic Rack and Pinion Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2031," offers a comprehensive analysis of the industry, which comprises insights on the Plastic Rack and Pinion market analysis. The report also includes competitor and regional analysis, and contemporary advancements in the market.

This report has a complete table of contents, figures,…

Wind Turbine Gearbox Market is Booming Worldwide | Chongqing Gearbox, Enercon, E …

Latest Study on Industrial Growth of Wind Turbine Gearbox Market 2023-2028. A detailed study accumulated to offer Latest insights about acute features of the Wind Turbine Gearbox market. The report contains different market predictions related to revenue size, production, CAGR, Consumption, gross margin, price, and other substantial factors. While emphasizing the key driving and restraining forces for this market, the report also offers a complete study of the future trends…

Electric Telescopic Lifting Column Market Is Booming So Rapidly | Baumeister & S …

Comprehensive Exploration of Global Electric Telescopic Lifting Column Market: Recent Study by The Market Insights

The recent study conducted by The Market Insights delves into the global Electric Telescopic Lifting Column market, providing an extensive examination of crucial aspects such as the market's geographical landscape, size, and revenue estimations. This research paper serves as an exhaustive exploration of all factors relevant to the market. Serving as a comprehensive reference, the research…

Portable Stair Climbers Market Size Historical Growth, Analysis, Opportunities a …

Los Angeles, United State: QY Research recently published a research report titled, "Global Portable Stair Climbers Research Report Market 2023". The research study presented in this report offers complete and intelligent analysis of the competition, segmentation, dynamics, and geographical advancement of the global Portable Stair Climbers market. It takes into account the CAGR, value, volume, revenue, production, consumption, sales, manufacturing cost, prices, and other key factors related to the global…

Global Wind Turbine Pitch Systems Market: Emerging Trends, Major Key Players Ost …

According to the report, The global Wind Turbine Pitch Systems market size is expected to reach $1.77 Billion by 2028 growing at the CAGR of 4.98% from 2021 to 2028. The growing need for electricity generated by wind energy, and also increased government initiatives to embrace offshore wind for electricity generation, are the primary factors driving the global wind turbine pitch systems market. Furthermore, throughout the forecast period, the growing…

Global Stationary Lapping Machine Market 2018 - PRAWEMA ANTRIEBSTECHNIK GMBH, SO …

Eminent Market Reports, recently published a detailed market research study focused on the “Stationary Lapping Machine Market” across the global, regional and country level. The report provides 360° analysis of “Stationary Lapping Machine Market” from view of manufacturers, regions, product types and end industries. The research report analyses and provides the historical data along with current performance of the global PP Pipe industry, and estimates the future trend of Stationary…