Press release

Focussing power with the new machine vice CENTRO Gripp

Drilling, milling, grinding - when machine processing material, it always comes down to one essential aspect: precision. It goes without saying that the clamping element is of major importance for consistent results. The ALLMATIC-Jakob Spannsysteme GmbH is now presenting its solution boasting extraordinary durability and highest precision. Thanks to the tried and tested 'grip system' developed by the company, clamping unfinished parts as well as already treated workpieces of different geometries is possible without any ado. Just like it is the case with the models T-Rex and TITAN, the exchangeable jaws of the new machine vice CENTRO Gripp with central clamping offer a maximum of flexibility.For almost 40 years ALLMATIC has been a synonym for competent performance and service as well as for highest quality. Customers appreciate this uncompromising approach. Today the company from Swabian Unterthingau is one of the worldwide leading manufacturers of clamping elements. From high-pressure clamping sets for conventional milling machines to complex clamping elements for flexible production centres: the experts in their industry always come up with the perfect solution for practically every field of application.

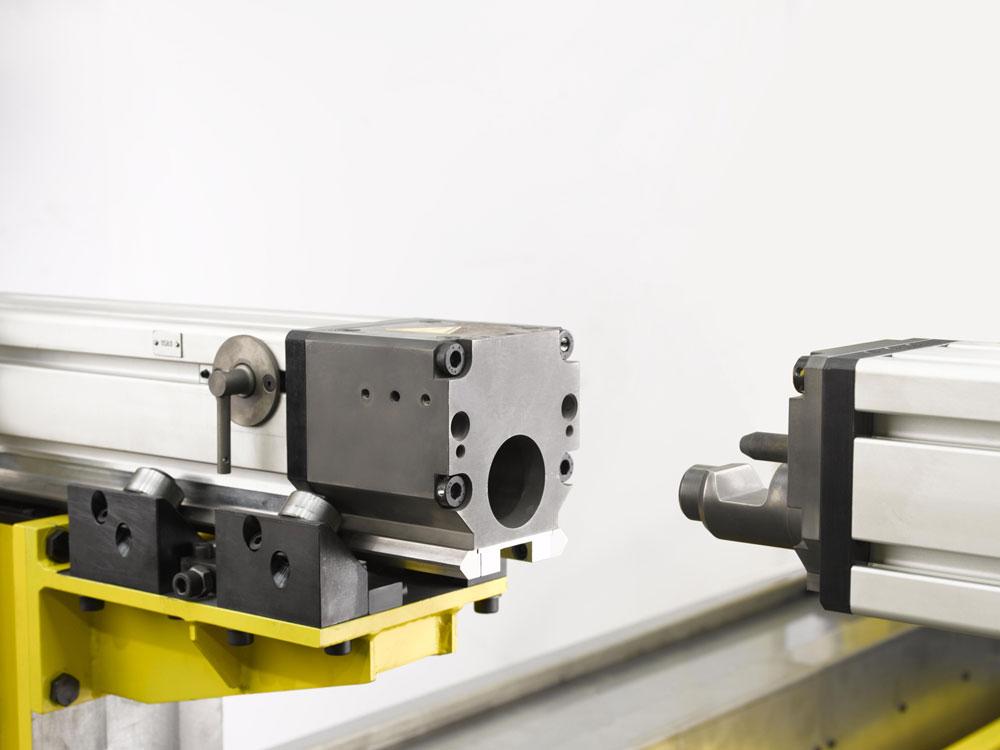

CENTRO Gripp gives evidence of ALLMATIC's incessant innovation spirit when it comes to developing elements which promise professional workpiece clamping. Just like all other products of the company's portfolio, the new all-round talent wins customers over with its high precision and product quality. Thanks to central clamping, the machine vice allows for great comfort during operation. The ideal access to the workpiece and the secure and interlocking clamping are extremely favourable aspects for treating five sides of workpieces. The clamping element can be built in horizontally which qualifies it for being used in vertical CNC milling machines. The bores in the clamping shoulders allow for mounting it right to the machine table. Its compact dimensions make it the first choice for five-shaft machining centres.

Absolute precision: the centre of the new machine vice is adjustable. The position of the workpiece is retained within close boundaries. In case of angular workpieces, the clamping element guarantees for excellent repeating accuracy. Depending on which clamping jaws are used, treated workpieces or unfinished parts of different kinds can be safely clamped. Possible fields of application are flame or saw cutting of cast pieces. In addition, the flexible system allows for embossing and clamping in just one operational step - without the need to fall back on an extra tool.

The vice is clamped with a torque wrench up to a maximum torque of 70 Nm. The clamping range is locked by relocating the exchangeable clamping jaws. By the way: the clamping jaws are another special feature of the clamping element. Thanks to the mobile step or pull-down jaws for clamping pre-machined workpieces as well as to the inserts with spiked ends and the pendulum jaws for unfinished parts with complex geometries, there is hardly a scenario which could not be realized with CENTRO Gripp. Depending on the grip stud insert, clamping ranges from ten to 300 millimetres are possible. Even large workpieces can be clamped safely - even in case of massive chip removal.

Quality has always played an elementary role at ALLMATIC. As a matter of course, the engineers from Swabia have focussed on extraordinary product quality of CENTRO Gripp, too. Hardened and ground slideways guarantee for long and safe operation without material fatigue. The fully enclosed maintenance-free high-pressure spindle easily stands the test for many years. Large lateral outlets facilitate chip removal and maintenance. No need to say, that the jaws as well as the grip stud inserts are made of high-quality material. This extremely high quality always guarantees perfect results.

For more information on CENTRO Gripp made by ALLMATIC please visit http://www.allmatic.de on the Internet.

About JAKOB GROUP:

JAKOB GROUP unites seven medium-sized companies from the driving, clamping, and automation technology as well as from the innovative fields of vacuum, ionic, and plasma technology under its umbrella. The individual companies work independently but feel obliged to cooperate closely. Thanks to this philosophy, customers can profit from multiple synergies.

About ALLMATIC-Jakob:

ALLMATIC-Jakob Spannsysteme GmbH has produced high-quality and high-precision clamping elements for almost 40 years. From high-pressure clamping sets for conventional milling machines to complex clamping elements: the company from Swabian Unterthingau offers the perfect solution for many different fields of application. Its high standards in product quality and its competent service make ALLMATIC a reliable partner in professional workpiece clamping.

Contact within the company

ALLMATIC-Jakob Spannsysteme GmbH

Jägermühle 10 | 87647 Unterthingau

Phone +49 (0) 8377 929 - 0

info(at)allmatic.de

http://www.allmatic.de

Press contact

knoefler-journalist . media + communications GmbH

Benjamin Knöfler, Ayenegbe Stephen

Nordring 53-55 | 63843 Niedernberg | Germany

Phone +49 (0)6028 - 80729 0

jakob(at)kj-media.com

http://www.knoefler-journalist.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Focussing power with the new machine vice CENTRO Gripp here

News-ID: 137853 • Views: …

More Releases from JAKOB GRUPPE

JAKOB Antriebstechnik is presenting its new transfer rail couplings at this year …

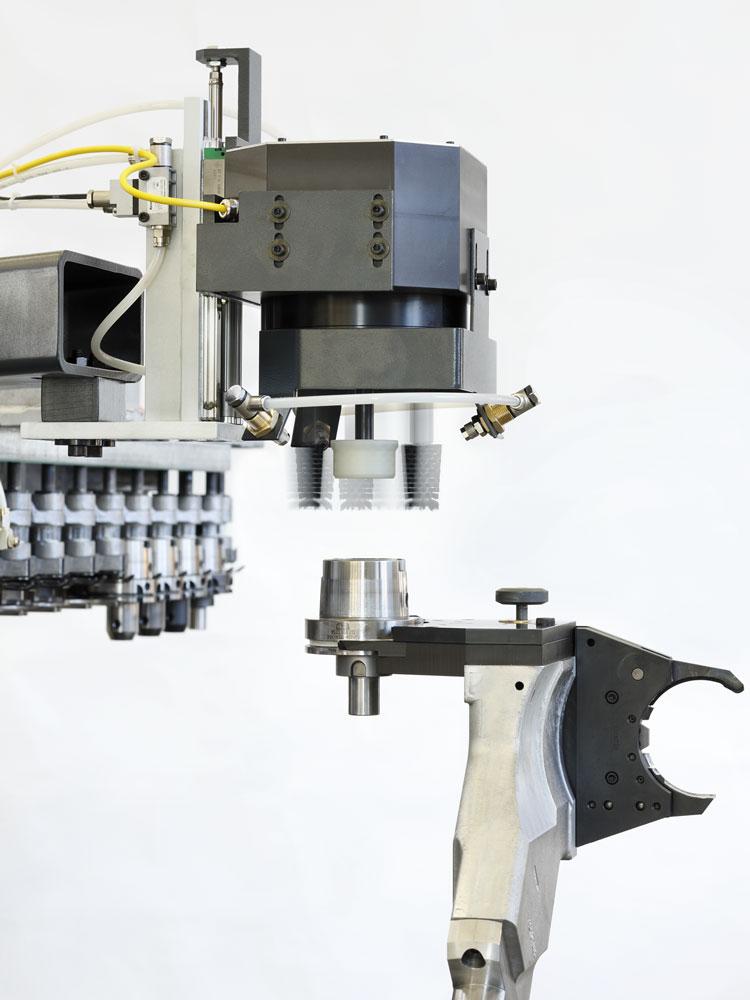

Increased performance thanks to automated set-up processes: due to the large number of different products, modern pressing plants nowadays - more than ever - face the challenge of making tool changes and setting-up processes of systems go off without a hitch. With regard to productivity, it goes without saying that set-up times play an essential role. State-of-the-art transfer rail couplings can contribute to increasing the economic efficiency and safety of…

Clean clamping solution: tool taper cleaning device by T+S-JAKOB

One of the most important criteria when expecting the treatment of work pieces in state-of-the-art milling machines to go off without a hitch is keeping the tool clamping force at a steady level despite changing tools. Even with properly shielded tool magazines and changers, it is almost impossible to avoid dirt - such as chips or cooling lubricant from the processing chamber - settling on the tool taper. In order…

Superfinish surfaces thanks to trail-blazing clamping technology

Actually, it is not exactly easy to improve a good product. Sometimes it is the small details that make a profound difference. Georg Forster, certified engineer at Supfina Grieshaber GmbH & Co. KG from Wolfach in German Baden-Wuerttemberg, says he knows that from prior experience as well. He is one of the 20 design engineers who develop and improve the systems used for surface treatment and the special Supfina 'superfinishing'…

More Releases for CENTRO

Best Ways a Personal Injury Lawyer El Centro Explains Class Actions

Legal harm does not always affect people one by one. Sometimes the same issue impacts dozens or even hundreds of individuals. When that happens, people often hear about group lawsuits and want clear answers. A personal injury lawyer El Centro https://millerlegalcenter.com/ residents speak with can explain how class actions work and when they apply.

This article focuses on understanding eligibility, participation, decision making, and outcomes. It is written for people who…

Led by Aldo Corbo, Centro Dentale Corbo to Expand with New International Supplie …

Image: https://www.abnewswire.com/uploads/110d20915208dbd6efd7230ff620bdd4.png

Aldo Corbo [https://www.centrodentalecorbo.it/], the CEO of the popular dental center Centro Dentale Corbo, has announced that in 2024, the center will be focusing on expanding its dental center nationally by adding new international suppliers.

Speaking to the media, Aldo Corbo said, "The key to entrepreneurial success is the audacity to look for new paths."

Centro Dentale Corbo has made of its dental services with its unique protocols and patents, specifically designed…

Revolutionize The Bedroom with Luxurious Matrimonial Bed Sheets from Centro Scam …

Carpenedolo - Centro Scampoli, a leading provider of premium home textile products, is thrilled to announce the launch of its exquisite collection of matrimonial bed sheets, designed to elevate your sleep experience to new heights of comfort and luxury.

At Centro Scampoli, we understand the importance of a good night's sleep and the role that high-quality bedding plays in achieving it. That's why we have poured our expertise and passion into…

Demand Side Platform Software Market is Going to Boom | Centro, Dataxu, Choozle

Advance Market Analytics published a new research publication on “Demand Side Platform Software Market Insights, to 2027″ with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market associated stakeholders. The growth of the Demand Side Platform Software market was mainly driven by the increasing R&D spending across the world.

Some of the…

Media Planning Software Global Market 2018: Key Players – comScore, SAP, Centr …

Media Planning Software Industry

Description

Wiseguyreports.Com Adds “Media Planning Software -Market Demand, Growth, Opportunities and Analysis Of Top Key Player Forecast To 2023” To Its Research Database

This report focuses on the global Media Planning Software status, future forecast, growth opportunity, key market and key players. The study objectives are to present the Media Planning Software development in United States, Europe and China.

Media planning software is a type of software used by advertisers…

Celebrate, Beautify and Unify Tucson - Barrio Centro Community Mural Unveiling

The Barrio Centro Association and Tucson Arts Brigade invite the entire community to celebrate the unveiling of the Barrio Centro Community Mural on Saturday, June 18th from 6:30 - 8:30 pm at Lucky Wishbone, 2712 E. 22nd Street. Join us for this free, fun-filled family event with food, music, speakers and performances. Trio Centrál will be playing Latin Jazz and Serenata will be playing Ranchera and Bolleros.

The…