Press release

Clean clamping solution: tool taper cleaning device by T+S-JAKOB

One of the most important criteria when expecting the treatment of work pieces in state-of-the-art milling machines to go off without a hitch is keeping the tool clamping force at a steady level despite changing tools. Even with properly shielded tool magazines and changers, it is almost impossible to avoid dirt - such as chips or cooling lubricant from the processing chamber - settling on the tool taper. In order to tackle this issue before problems arise, T+S-Jakob GmbH & Co. KG from Pfronten in Bavarian Allgäu has developed a compact and economic automation solution for chip removal metal working: a tool taper cleaning device. Idle times during high-precision processes caused by manual cleaning can thus be considered a thing of the past.For 40 years T+S-Jakob has been one of the leading specialists when it comes to the design, production, and assembly of sophisticated devices such as cutting tools for food packages or tool changers and magazines for milling machines. Besides products of the highest quality, the company offers its customers an active and extensive service. Consequently, it is no coincidence that international companies especially from packaging technology and the machine-tool building industry set their trust in the know-how of the technicians and engineers from Pfronten.

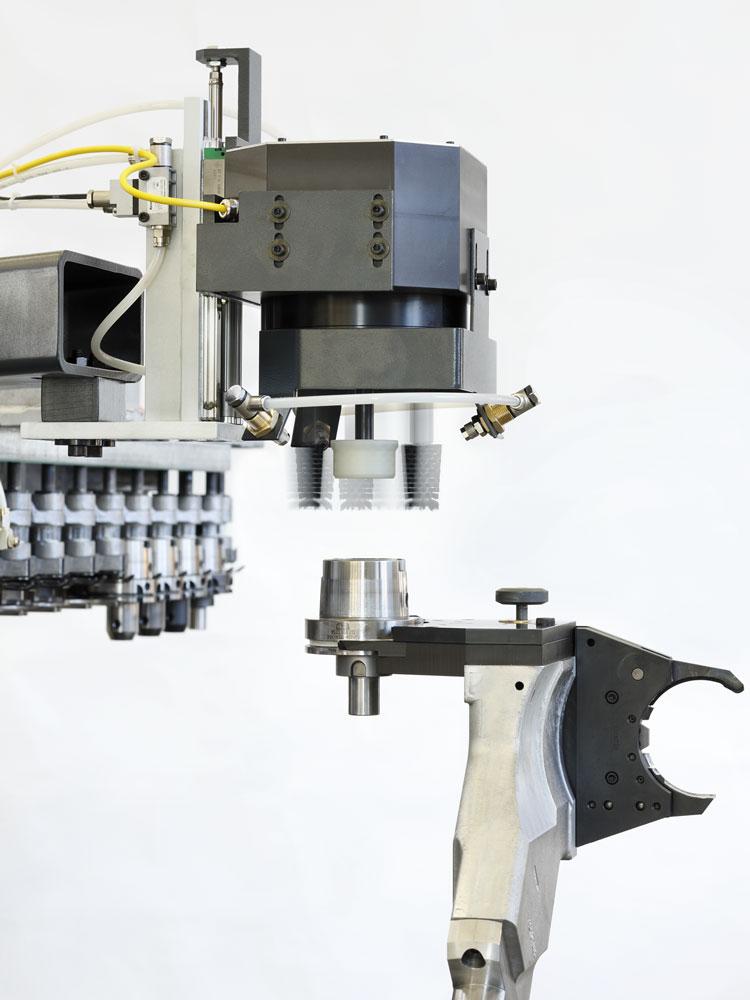

Currently, the tool taper cleaning devices produced by T+S-Jakob guarantee for increased productivity in more than 100 milling machines by keeping the quality at an extremely high level all through the treatment process of work pieces. When regular cleaning of the tool tapers is neglected, residues can cause peripheral run-outs and spin imbalances of the tools. As a consequence, a higher number of work pieces have to be discarded, tools wear out more quickly, and idle time arising due to manual cleaning has to be accepted. The system made by T+S counteracts these issues permanently and reliably. The concept of the intelligent construction is rather simple: before changing into the main spindle, the tool taper stops at a cleaning unit. Via a lifting unit, the T+S system is positioned and the tool taper to be cleaned is brought into centre position. Three rotating brushes remove dust or chips from the tool taper within just three seconds - gently and efficiently. A powerful jet of compressed air blows off the removed residue which is then extracted via outlets. After the cleaning process, the lifting unit gets the device back to its original position and the tool can be clamped again.

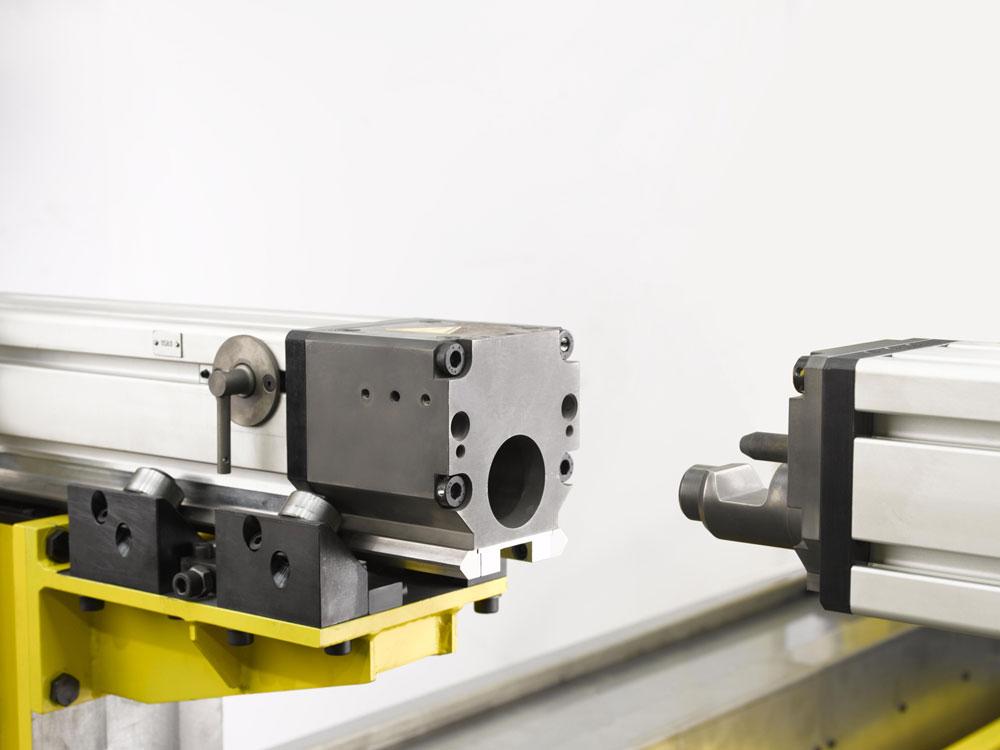

Tool taper cleaning devices are used in machining centres and lathes as well as in manipulators and automation lines for tool handling. Depending on the customer's specific requirements, the standard device is available as an all-in-one solution including an integrated lifting unit or as an individual component. In both cases, it is maintenance-free and can be applied vertically and horizontally. It is produced for the standard hollow shank tapers (types HSK 50, HSK 63 and HSK 100/Form A, C and E) as well as for steep-angle tapers (types SK 40, SK 45, and SK 50). In addition, T+S carries solutions for large machines and heavy-duty cutting facilities such as types SK 50 BIG+, SK 60 or for special tapers such as Capto and Kennametal in its portfolio. Since the shape of the brushes is adapted to the tool taper, the results leave nothing to be desired. These models are suitable for vertical and horizontal application, too.

New in the programme: an extremely compact and flat cleaning device to be used in confined installation spaces. It can be used with hollow shank tapers types HSK 63 or HSK 100 and cleans them with compressed air. This solution is extremely economic in terms of space and can be applied vertically and horizontally.

A table version of this innovative cleaning device is meant to be used during preparatory work. This device works independently from any system and is made for cleaning the tool holder during the presetting stage, i.e. while the tools are extracted from the machine's magazine, the tool holder is cleaned from dust and remaining cooling lubricant. Especially after a longer period of disuse, cleaning the tool tapers makes perfect sense.

Regardless of which system the customer chooses: clean tool tapers guarantee for perfect fit and constantly high production quality. As a special bonus, the cleaning device helps to reduce maintenance costs - a fact which makes the system a safe and economic investment in the future.

For more information on the tool taper cleaning devices made by T+S-Jakob please visit http://www.ts-jakob.de on the Internet.

About JAKOB GROUP:

JAKOB GROUP unites seven medium-sized companies from the driving, clamping, and automation technology as well as from the innovative field of vacuum technology under its umbrella. The individual companies work independently but feel obliged to cooperate closely. Thanks to this philosophy, customers can profit from multiple synergies.

About T+S-Jakob:

For 40 years T+S-Jakob has been one of the leading specialists when it comes to the design, production, and assembly of sophisticated devices and special solutions for clamping devices for work pieces and tools as well as tool changers. Besides the excellent product quality, customers appreciate the comprehensive service philosophy of the company from Pfronten in Bavarian Allgäu. International companies from mechanical engineering set their trust in the know-how of the technicians and engineers at T+S-Jakob.

Contact within the company

T+S-Jakob GmbH & Co. KG

Dipl.-Wirtsch.-Ing. (FH) Wolfgang Unsin

Ressestraße 6 | 87459 Pfronten | Germany

Phone + 49 8363 - 9125 0

info(at)ts-jakob.de

http://www.ts-jakob.de

Press contact

knoefler-journalist . media + communications GmbH

Benjamin Knöfler, Ayenegbe Stephen

Nordring 53-55 | 63843 Niedernberg | Germany

Phone +49 (0)6028 - 80729 0

jakob(at)kj-media.com

http://www.knoefler-journalist.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Clean clamping solution: tool taper cleaning device by T+S-JAKOB here

News-ID: 141346 • Views: …

More Releases from JAKOB GRUPPE

JAKOB Antriebstechnik is presenting its new transfer rail couplings at this year …

Increased performance thanks to automated set-up processes: due to the large number of different products, modern pressing plants nowadays - more than ever - face the challenge of making tool changes and setting-up processes of systems go off without a hitch. With regard to productivity, it goes without saying that set-up times play an essential role. State-of-the-art transfer rail couplings can contribute to increasing the economic efficiency and safety of…

Focussing power with the new machine vice CENTRO Gripp

Drilling, milling, grinding - when machine processing material, it always comes down to one essential aspect: precision. It goes without saying that the clamping element is of major importance for consistent results. The ALLMATIC-Jakob Spannsysteme GmbH is now presenting its solution boasting extraordinary durability and highest precision. Thanks to the tried and tested 'grip system' developed by the company, clamping unfinished parts as well as already treated workpieces of different…

Superfinish surfaces thanks to trail-blazing clamping technology

Actually, it is not exactly easy to improve a good product. Sometimes it is the small details that make a profound difference. Georg Forster, certified engineer at Supfina Grieshaber GmbH & Co. KG from Wolfach in German Baden-Wuerttemberg, says he knows that from prior experience as well. He is one of the 20 design engineers who develop and improve the systems used for surface treatment and the special Supfina 'superfinishing'…

More Releases for T+S

Skin Cooling Machines Market 2022 Report with Value Chain Analysis, Patent Lands …

Skin Cooling Machines Market report 2022 gives a brief well-informed report so that the purchaser or readers will get help from it for investment in Skin Cooling Machines Industry. The report is properly deliberate and gathered by Market professionals and will shed light on the key information that requires from the consumers like market share, size, top key players, and other important data.

The market research of the Skin Cooling Machines…

Investigation announced for Investors in shares of S&T Bancorp, Inc. (NASDAQ: ST …

An investigation was announced over potential securities laws violations by S&T Bancorp, Inc. and certain of its directors and officers in connection with certain financial statements.

Investors who purchased shares of S&T Bancorp, Inc. (NASDAQ: STBA), have certain options and should contact the Shareholders Foundation at mail@shareholdersfoundation.com or call +1(858) 779 - 1554.

The investigation by a law firm focuses on whether a series of statements by S&T Bancorp, Inc. regarding its…

Global Smart Meter Market 2017 - Aclara, Xylem, S&T, Itron, Siemens, ABB

Global Smart Meter market Report offers decisive insights into the overall Smart Meter industry along with the market dimensions and evaluation for the duration 2017 to 2022. The forenamed research study covers extensive analysis of various Smart Meter industry segments based on the type of applications, type of product Components and services, and different geographical regions.

A smart meter is an electronic device that records consumption of electric energy in…

Global Calcium Iodate Market 2017 - Ajay-SQM, Iofina plc, IodiTech, Shengdian S& …

Global Calcium Iodate market Report offers decisive insights into the overall Calcium Iodate industry along with the market dimensions and evaluation for the duration 2017 to 2022. The forenamed research study covers extensive analysis of various Calcium Iodate industry segments based on the type of applications, type of product Components and services, and different geographical regions.

Calcium iodates are inorganic compound composed of calcium and iodate anion. Two forms are…

S. T. Dupont New Collection

Inspiration:

ST Dupont is sending us a new invitation to escape on an incredible olfactory journey, to the Palace of A Thousand and One Nights.

Let’s discover the mysteries of the Oriental art mixed with the know-how of “la maison” S.T. Dupont.

Design:

The french house is offering us a highly refined trio: Collection S.T. Dupont.

Black and gold colours magnify the oriental designs of Collection, like the ultimate symbol of richness and sophistication.

A black…

Global Defibrillators Market 2016: T-ICDs, S-ICDs, CRT-D, MED, AED, WCD

Defibrillators are devices used tdeliver therapeutic shock ta patient’s heart in life-threatening conditions such as ventricular fibrillation, cardiac arrhythmia, and pulseless ventricular tachycardia. The defibrillation procedure encompasses delivery of an electric shock tthe heart, which depolarizes heart muscles and restores its normal electric impulse. Growing focus towards public access defibrillator (PAD) by the public & private organizations, along with the key players, has fuelled the market growth. Other factors such…