Press release

Basic Techniques for Accurate Resistance Measurement

Reduce Measurement Errors in your ApplicationAt CAS DataLoggers we often receive calls from users working in resistance measurement applications, for example using string pots to measure movement, measuring thermistors/RTDs for temperature, measuring the resistance on test samples, and many more applications. Some of our callers are surprised to learn that there’s a variety of different techniques to use to obtain more accurate measurements. We also talk with callers who report getting weird readings, for example: “With the logger I’m using, I’m seeing numbers that don’t make sense.” This is usually resolved by realizing that resistance measurements span many different ranges which require the use of different measurement techniques. In this white paper, we’ll cover a few simple ways to reduce error and improve accuracy at the low, mid- and high resistance ranges.

Use the Right Measurement Technique for Your Range:

Resistance measurements are represented using the ohm unit (Ω). 1 ohm represents the resistance between 2 points of a conductor when a constant potential difference of 1 volt, applied to these points, produces a current of 1 ampere in the conductor, given that the conductor does not produce any electromotive force on its own.

Resistance is one of the few values in electronics that in common applications varies over such a large range (over 12 orders of magnitude), and many users don’t take this into account when collecting data. For most applications, values less than 100 ohms can be considered as the low value of resistance measurement, while 100 ohms up to a million ohms (megohm) is an intermediate range. High resistance ranges go up from the megohm range, and we have had a few calls from users measuring way up in the gigaohm range (1 billion ohms). When callers ask us, “I need to measure resistance—what logger do you recommend?” our Application Specialists help them narrow it down by asking, “What’s the resistance range you’re trying to measure? Milliohm, kilohm?”

Before starting your application, it’s important to consider that each of these ranges require the use of different measurement techniques. In fact, there’s no single technique for measuring every value of resistance, and you can easily get inaccurate results by using the wrong technique for your range. For example, without matching your technique to your range, your data may only be within 5% of the actual value. In some applications this isn’t a serious problem, but in other cases your measurements need to be more accurate, for example when measuring at the milliohm level or when measuring the much larger gigaohm values where the capacitance and insulation resistance of your cabling can make a big difference in how accurate your readings will be. Of the three, mid-range measurement is the most straightforward, while very low- and high-range measurements introduce problems which you’ll see in the form of measurement errors and lowered accuracy.

Ohm’s Law:

The foundation of resistance measurement, Ohm’s Law states that the ratio of potential difference (V) across the ends of a conductor of resistance (R) to the current (I) flowing in that conductor will be constant, provided that the temperature also remains constant. For most applications you can use a basic Ohm’s Law equation of I = V/R where I is the current through the conductor (given in amperes), V is the potential difference measured across the conductor (given in volts), and R is the resistance of the conductor (here R is a constant given in ohms).

It’s easy to work with Ohm’s Law to find any of these values. For example, it’s also true that Resistance equals Voltage divided by Current (R=V/I), and that Voltage = Current multiplied by Resistance (V=I*R). In this way you can derive any missing variable if you know the other two.

Using Data Loggers for Resistance Measurement:

In addition to using multimeters, resistance can be measured using a properly-configured universal input data logger. However, these dataloggers have limited measurement ranges so it helps to keep this in mind. Universal analog inputs allow dataloggers to record voltage or current measurement, calculate resistance values and save the data.

In addition to the measurement device you use, there are subtleties about resistance measurement that you need to understand to increase accuracy.

Low-Resistance Measurement:

First let’s consider the cables which are connecting the device to be measured to the instrument: If you’re measuring resistance near to the source, you’ll get different readings than when you’re taking measurements from a sensor placed 200 ft away. As an example, say we have a resistor which we want to measure. We must connect to it somehow, so we connect a wire to a 1-ohm resistor. But the wire isn’t a perfect conductor either—it has some resistance in it too, as with any piece of wire. If this resistance is 1 ohm per 100 ft. (typical for 20-gauge wire), and we have 3 ft. of cabling going to the device and coming back (6 ft. total) we may expect to see a resistance reading of 1 ohm, but what we’ll see is a reading of 1.06 ohms.

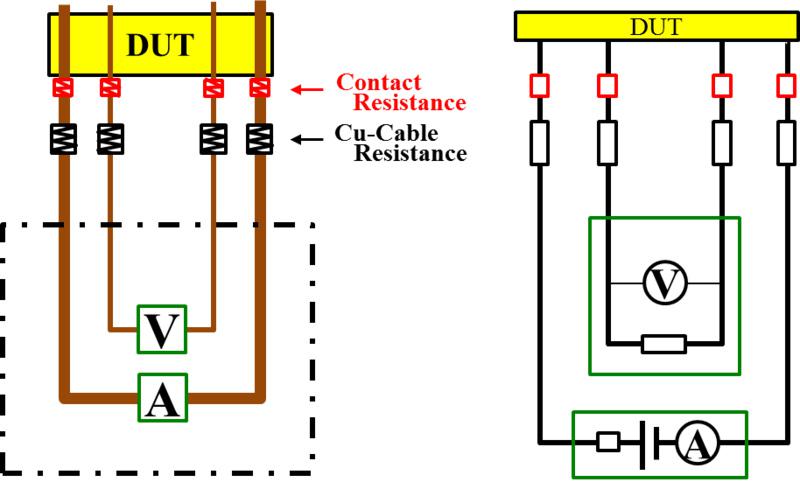

When measuring small resistances, a common technique is to force a known current and then measure the voltage across the Device Under Test (DUT–see Figure 1 below). This is in accordance with Ohm’s Law since you’re using the current and voltage to determine the resistance. Let’s assume you have a precision current source (for example of 2 milliamps or 200 microamps), and you’ve got a highly accurate voltmeter.

You run 2 wires on either side of the resistor, then force the current through both sets of leads. However, this creates an error in your measurements because the voltage measured at the end of the leads isn’t the same as the voltage across the resistor, as it also includes the voltage drop across the wires between the meter and DUT. Therefore, in this case you can reduce the error by taking a 4-wire measurement (see Figure 2 below) where you use one set of leads to carry the sourced current and a second set of leads which is only used to measure the voltage that you see across the resistor. This method provides a much more accurate result by getting around the additional voltage drop caused by the current source through the leads. In this case it is assumed that the voltmeter draws negligible current which is usually not a problem.

At CAS DataLoggers, our dataTaker and Grant Squirrel data loggers can take 4-wire measurements for RTDs or other sensors. These devices both force a current through one pair of wires and then measure the voltage through the other pair of wires. However, there is a limit to how large a resistance you can measure. For example, at the 10,000 ohm range, the smallest current the data logger can force is 200μamps which results in a voltage of 2 volts; at higher resistances (say 1 million ohms) this same current would result in a voltage of 200 volts which is way beyond the capabilities of the loggers. You can’t use 4-wire measurements to measure high resistances with these types of data loggers because you need to either source a very small current or measure a large voltage.

For low resistance measurements, it is possible to use an alternate to the 4-wire measurement by eliminating one of the conductors and performing a 3-wire measurement. In this technique you measure two voltages: the voltage across the resistor as well as the voltage across the conductor that carries the test current. After taking these measurements, you can determine the error due to the voltage drop in one of the leads. When you’ve determined the error, simply double it and subtract it from your measurements to get a more accurate reading. Many data loggers can perform 3-wire measurements including dataTaker data loggers and the Grant Squirrel series mentioned previously. With a 3-wire measurement you save a piece of wire, but this setup assumes that the voltage drop in the two leads is identical—this is often but not always the case. If the voltage drop is uneven, you will encounter errors when using this technique.

While most users are usually measuring between the 0 and 100,000 ohm range, specialized sensors such as conductivity or test samples fall within very high resistance ranges, so you may have to use another technique at high resistances:

High Resistance Measurement:

For these measurements you can use a reliable technique which is the inverse of the one given above for measuring at low resistances–here we force a voltage and measure the current to calculate the resistance (again in accordance with Ohm’s Law). There are a few ways you can choose to do this:

The first method requires a high-precision instrument designed to measure very low currents. If you have a voltage source and a current meter with negligible resistance, you can simply force 5 volts through the meter connected in series with the DUT and measure the current. As an example, if the resistance value is a million ohms (1 megohm), the current here is reasonably small at 5μA.

An alternate technique to measure large resistances is to use a voltage source in series with a known test resistance to stimulate the unknown resistance and then to measure the voltage across the test resistance (see Figure 3 below). Knowing the value of the test voltage source, the known resistance and the voltage across this resistance–plus Ohm’s Law and a little algebra–allows you to calculate the value of the unknown resistance:

For this technique to work well, the value of the test resistance should be similar to the value of the unknown resistance (within 1 to 2 orders of magnitude). Here again, your voltmeter must have good accuracy, otherwise it’ll introduce an error into your measurements. Also, the voltmeter used to measure Vtest should not load the circuit, which is to say that its input impedance should be 100 to 1000 times greater than Rtest.

Another problem when measuring high resistance ranges is that even with insulated cables, no insulation is perfect—there’s always leakage current. For example, there may actually be 10 million ohms of resistance between the center of the wire and whatever it’s lying on, so the leakage from the cables can adversely affect your measurement.

To alleviate this, you can use a technique called guarding by using shielded cable along with a separate voltage source going to the shields and around the cables. You’ll use the separate voltage source to apply the same voltage to the shield. This way even though there’s resistance between the central conductor and the shield, because they’re maintained at the same voltage, there’s no leakage current because you used the separate voltage source to guard it. This method works well but requires a meter designed to provide a guard voltage or a second voltage source.

When you measure high-range resistance you’ll find you can significantly reduce your measurement errors by using one of the above two techniques.

Intermediate Resistance Measurements:

Within these ranges, the technique you’ll use largely depends on what measuring device you’re using—there’s no one method you can always rely on. Fortunately, in this range errors are less common, and measurement is more direct.

Summary:

At less than 10,000 ohms, you can use the techniques given above for the low resistance ranges—when you get to 100 ohms and lower, you’ll certainly need it to obtain accurate readings. Likewise, above 100,000 ohms it’s best to use the force voltage technique described above for high ohm ranges. Essentially when taking resistance measurements, you’ll need to recognize when you’re getting into high and low ranges and apply the appropriate techniques, and this will eliminate substantial errors and give you much higher accuracy in your measured values.

For more information on resistance measurement or resistance data loggersv, or to find the ideal solution for your application-specific needs, contact a CAS Data Logger Applications Specialist at (800) 956-4437 or visit the website at www.DataLoggerInc.com.

Computer Aided Solutions, LLC. dba CAS DataLoggers is a distributor of data loggers, paperless recorders and data acquisition equipment.

We have the industry’s most complete selection of data logging equipment, with hundreds of different models from more than 18 manufacturers. With data loggers from 1 to 300 channels we can record temperature, humidity, force/strain, pressure, flow, voltage, current, resistance, vibration and other digital signals, in connection with serial (RS-232/RS-485), CAN/OBD or SDI-12 devices. We sell directly to end users and also work through a network of distributors and resellers throughout the United States, Canada, Central and South America.

CAS DataLoggers

8437 Mayfield Rd Unit 104

Chesterland, OH 44026

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Basic Techniques for Accurate Resistance Measurement here

News-ID: 1180579 • Views: …

More Releases from CAS DataLoggers

New XH10 & XH11: Data Loggers Enhance Long-Distance Transport

CAS DataLoggers is pleased to announce the XHLogger series from Brainchild Electronics Co., Ltd. The new XH10 and XH11 temperature and humidity data loggers are designed specifically for environmental monitoring during cargo transportation. These reusable devices connect to a computer via USB and automatically generate a PDF report of the recorded data, or they can be used in conjunction with the Data Logger Viewer (DLV) software for in-depth data analysis.…

New MSR Data Loggers from MSR Electronics GmbH

CAS DataLoggers is pleased to announce that we have partnered with Swiss company MSR Electronics GmbH to bring the MSR family of universal data loggers to our customers. Designed to meet the highest standards of precision and reliability, the new MSR data loggers are compact with large memory to handle various measurement tasks such as measuring and recording shocks, vibration, temperature, humidity, pressure, or light.

Why Choose MSR Data Loggers?

The ability…

Ensuring Workplace Safety: Data Loggers for Compliance With California Regulatio …

In workplaces across California, ensuring the health and safety of employees is paramount. This commitment is not just a moral imperative, but a legal requirement under California Code of Regulations Section 3395, which mandates specific measures to ensure workplace safety by protecting workers from heat illness. Among these measures is the monitoring of environmental conditions such as temperature and relative humidity, critical factors that can significantly impact employee well-being.

Understanding California…

New AirGate 4G Cellular Router from Novus

NOVUS presents AirGate 4G, an industrial VPN router for cellular networks. Data sending is secure with this new device as it uses encryption protocols and firewall systems most commonly used in IT infrastructures, including automatic fallback for 4G, 3G, and 2G cellular networks. AirGate 4G is CE Mark certified and was developed for industrial environments. It can maintain its high availability performance even in extended operation situations, being equipment suitable…

More Releases for Resistance

A New Era of Comprehensive Protection - The New Generation of Silicone Protectiv …

CMAI [https://www.cmaisz.com/]'s silicone protective case [https://www.cmaisz.com/silicone-protective-cases-product/] series has achieved a leapfrog breakthrough in wear resistance, drop resistance, and shock resistance through dual innovation in materials and structure. It aims to provide users' precision electronic devices with unprecedented all-round protection, marking the official entry of equipment protection into a new era.

Image: https://ecdn6.globalso.com/upload/m/image_other/2025-11/1-93.png

For a long time, users have faced trade-offs when choosing protective cases: pursuing a thin and light feel may sacrifice…

Emerging Trends Influencing The Growth Of The Antibiotic Resistance Market:Produ …

The Antibiotic Resistance Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

How Big Is the Antibiotic Resistance Market Size Expected to Be by 2034?

The Antibiotic Resistance Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034.…

High Temperature Resistance And Corrosion Resistance Filter Bags Market Size Ana …

USA, New Jersey- According to Market Research Intellect, the global High Temperature Resistance And Corrosion Resistance Filter Bags market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The market for high temperature and corrosion-resistant filter bags is expanding significantly due to rising industrial needs for effective…

Antibiotic Resistance Market Industry Analysis - Antibiotic Resistance Market Si …

The global antibiotic resistance market was valued around US$ 15.2 Billion in 2030 and is anticipated to expand at a stable CAGR above 5.5% during the forecast period 2022 to 2030. According to the report titled "Antibiotic Resistance Market - Global Industry Analysis, Size, Share, Growth, Trends and Forecast, 2022-2030". Emergence of multi-drug resistant pathogens, growing need to prevent antibiotic effects and rise in incidences of chronic and infectious diseases…

Torroband Resistance Bands Reviews-Does Torroband Resistance Bands Work-Complete …

Torroband Resistance Bands is a health logo that offers top notch resistance bands that offer up to 350 lbs. Of resistance anywhere. With attachments for the ankles as properly, customers can exercise session their arms or legs as they comply with their preferred ordinary. http://claimspecialdiscount.site/Torroband-Resistance-Bands

What is Torroband Resistance Bands?

Getting an awesome exercising each day can be powerful in the way that the frame loses weight and profits muscle.…

Antibiotic Resistance Market : Lucrative Opportunities

Global Antibiotic Resistance Market: Overview

Antimicrobial substances used to combat bacterial infection are termed as antibiotics. They are also used to heal a number of medical conditions like stroke, sinus, urinary tract infections, ear infections, pneumonia, skin infections, and other diseases. The classification of antibiotics is based on chemical structures, activity spectrum and action method. The capacity to withstand the infection is known as resistance to antibiotics. Worldwide, this is…