Press release

Electromagnetic NDT Market is Set to Garner Staggering Revenues by 2026

Nondestructive testing (NDT) is the process of inspecting materials, components and assemblies in order to find discontinuities or differences in their characteristics without damaging the particular system. NDT testing through electric currents or magnetic fields or both to observe the electromagnetic response is termed as Electromagnetic NDT. The basic principle of working for Electromagnetic NDT is induction of an electric current or magnetic field into a conductive part, after which the response of the material with respect to the induced current is evaluated. These techniques are widely used to detect and measure faults, thickness, electrical conductivity, bond or weld integrity and also to perceive the presence of rebar or metals.Stringent government regulations regarding safety and environmental issues are currently driving the market for Electromagnetic NDT. Increasing demand for NDT from the verticals such as industrial, oil & gas, automotive and aerospace, mainly for investigating the integrity of equipment and assets, are further strengthening the market growth. However, factors such as high cost of equipment and technical anomalies are holding back the market growth.

A sample of this report is available upon request @ https://www.futuremarketinsights.com/reports/sample/rep-gb-1415

Market Overview:

NDT differs from the other destructive testing techniques. It is used on most of the materials, components and assemblies which are used during operations, as against destructive testing, which has its application limited to few systems. Destructive tests are generally utilized for examining the physical characteristics of materials such as ductility, tensile strength, yield, impact resistance, fracture toughness and fatigue strength. On the other hand, NDT are used for discontinuities and differences in material properties, which cannot be effectively traced using destructive testing.

Market Dynamics:

Improved sensitivity to small cracks, efficient detection of surface and near surface defects, requirement of minimum part preparation are few of the significant factors driving the growth of Electromagnetic NDT market. Additionally, Electromagnetic NDT enables inspection of complex shapes and sizes of conductive materials, further propelling the adoption of these techniques in the various industry verticals.

However, the Electromagnetic NDT market growth is restrained by the high cost of equipment (which are used at several stages of testing) and lack of skilled technicians. Additionally, technical limitations encountered during Electromagnetic NDT have compelled the industry to look out for the alternatives, in turn restraining the market growth. Some of these limitations include accurate inspection of conductive materials only, significant interference of surface finish, limited depth of penetration, and mandatory requirement of roughness reference standards for setup.

Growing demand of ensuring product reliability, maintain a uniform quality level and lower production costs, during manufacturing and fabrication stages, across various industries is expected to drive the growth of the Electromagnetic NDT market during the forecast period. Additionally, technological advances in the field of electromagnetism and related NDT techniques have increased its deployment in in complex industry operations. For instance, Electromagnetic NDT are being readily used in the inspection of reactor vessels of nuclear power plants, which earlier utilized ultrasonic techniques.

Market Segmentation:

Electromagnetic NDT market is mainly classified on the basis of type and geography.

On the basis of type, Electromagnetic NDT is segmented as:

Eddy Current Testing

Alternating Current Field Measurement (ACFM)

Remote Field Testing (RFT)

Others (Barkhausen Noise Analysis (BNA) method, Ground Penetrating Radar (GPR) and Magnetic Resonance Imaging (MRI))

Among these techniques, eddy-current testing is the most commonly used and is employed for near-surface cracks and corrosion detection, in metallic objects such as tubes and aircraft fuselage.

On the basis of geographies, global market of Electromagnetic NDT is segmented as:

North America

Latin America

Western Europe

Eastern Europe

Asia Pacific Excluding Japan

Japan

Middle East & Africa

To view TOC of this report is available upon request @ https://www.futuremarketinsights.com/toc/rep-gb-1415

Key Market Players:

Key players in the industry include General Electric, Olympus Corporation, NDT Technologies, Institut Dr. Foerster GmbH & Co. KG, Zetec Inc., Magnetic Analysis Corporation and Eddyfi.

About Us

Future Market Insights is the premier provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in London, the global financial capital, and has delivery centres in the U.S. and India.

FMI’s research and consulting services help businesses around the globe navigate the challenges in a rapidly evolving marketplace with confidence and clarity. Our customised and syndicated market research reports deliver actionable insights that drive sustainable growth. We continuously track emerging trends and events in a broad range of end industries to ensure our clients prepare for the evolving needs of their consumers.

Contact Us

U.S. Office

616 Corporate Way, Suite 2-9018,

Valley Cottage, NY 10989,

United States

T: +1-347-918-3531

F: +1-845-579-5705

Email: sales@futuremarketinsights.com

Web:https://www.futuremarketinsights.com/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electromagnetic NDT Market is Set to Garner Staggering Revenues by 2026 here

News-ID: 1064556 • Views: …

More Releases from Future Market Insights

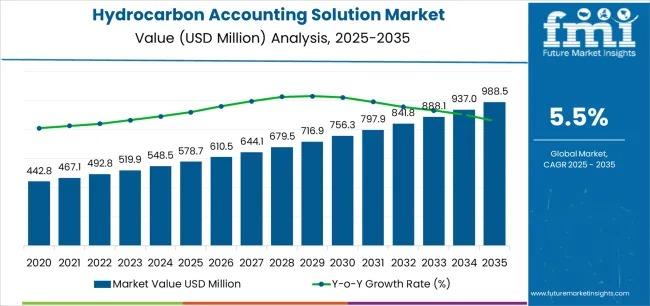

Hydrocarbon Accounting Solution Market Set to Reach USD 988.4 Million by 2035 as …

The global hydrocarbon accounting solution market is projected to expand from USD 578.7 million in 2025 to USD 988.4 million by 2035, registering a steady compound annual growth rate (CAGR) of 5.5%. This expansion reflects a structural shift across the oil and gas industry toward digital platforms capable of delivering accurate production allocation, automated reconciliation, and regulatory compliance in increasingly complex operational environments. As production portfolios expand across unconventional resources,…

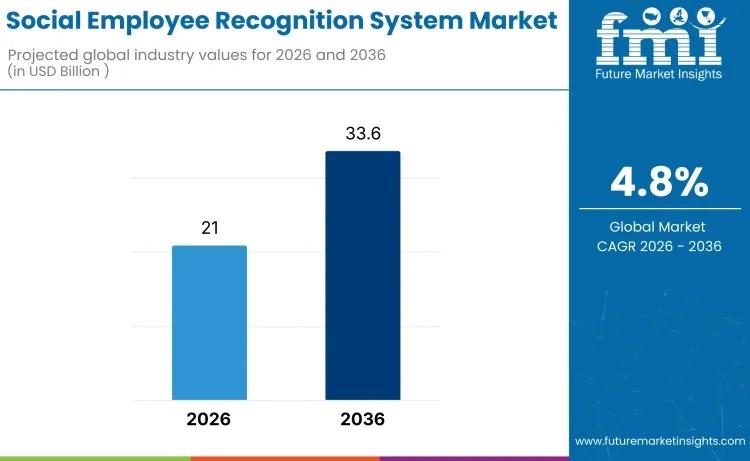

Social Employee Recognition System Market to Reach USD 33.6 Billion by 2036 as D …

The global social employee recognition system market is entering a new phase of strategic expansion, projected to grow from USD 21.0 billion in 2026 to USD 33.6 billion by 2036, reflecting a compound annual growth rate (CAGR) of 4.8%. This sustained growth trajectory highlights the increasing importance of employee engagement technologies in shaping organizational culture, enhancing workforce productivity, and supporting talent retention initiatives across diverse industries.

Organizations worldwide are prioritizing digital…

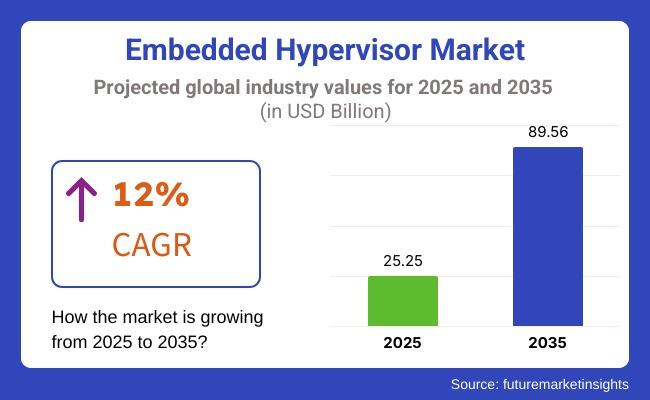

Embedded Hypervisor Market Set for Strong Expansion as Software-Defined Vehicles …

The global embedded hypervisor market is entering a period of accelerated expansion, driven by rising adoption of software-defined architectures across automotive, aerospace, industrial automation, and telecommunications industries. The market is projected to grow from USD 25.25 billion in 2025 to USD 89.56 billion by 2035, advancing at a compound annual growth rate (CAGR) of 12%, reflecting the increasing importance of secure, high-performance virtualization in mission-critical embedded systems.

Embedded hypervisors-specialized software layers…

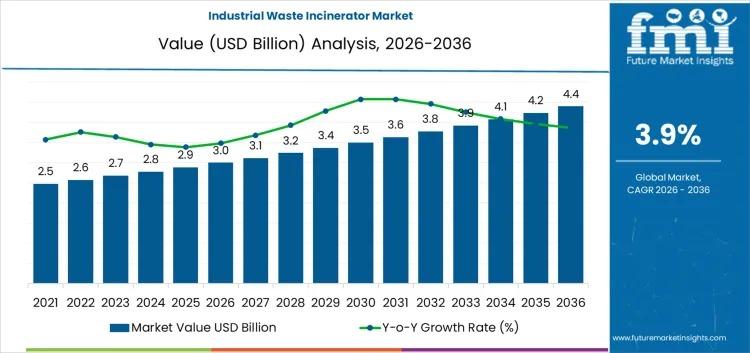

Industrial Waste Incinerator Market to Reach USD 4.4 Billion by 2036 as Industri …

The global industrial waste incinerator market is projected to grow from USD 3 billion in 2026 to USD 4.4 billion by 2036, registering a compound annual growth rate (CAGR) of 3.90% over the forecast period. This steady expansion reflects increasing global pressure on industrial operators to adopt sustainable waste management practices, comply with stringent environmental regulations, and reduce landfill dependence while improving operational efficiency.

As industrial sectors expand production capacity and…

More Releases for NDT

Seamless Digital RT Workflow with DRIVE NDT and D-Tect X from DÜRR NDT

For an optimal digital workflow in radiographic testing (RT), the X-ray inspection software D-Tect X can be integrated with the NDT management software DRIVE NDT. The closely meshed interaction between DRIVE NDT and D-Tect X means that a large part of the process takes place automatically. This not only saves time, but the automatic exchange of data also minimizes the possibility of human error. As all the steps and processes…

Rapid CUI Inspection with the DRA 3543 NDT Flat Panel Detector from DÜRR NDT

NDE Solutions Pty Ltd, located in Adelaide, South Australia with a team of over 60 employees provides non-destructive testing and inspection solutions to the oil and gas, defence, power, and mining industries.

NDE Solutions has been using the DÜRR NDT DRA 3543 digital flat panel since 2021 in combination with Iridium-192 radiation sources to perform Corrosion-Under-Insulation (CUI) radiography for confirming pipe wall loss in oil and gas plants and refineries. The…

DRIVE NDT enables DEKRA to increase its efficiency with digital NDT workflow man …

DEKRA has approximately 48,000 employees and ranks as one of the foremost testing companies worldwide. A pioneering team is introducing the innovative DRIVE NDT to organize non-destructive testing and its peripheral processes at the BAYERNOIL site in Neustadt.

Digital processes are firmly embedded in all industrial fields these days. The resulting advantages are clearly seen by all companies and industries and their potential is also increasingly recognized for non-destructive testing. Benjamin…

Corrosion-Under-Insulation Inspection Made Easy with the CR 35 NDT from DÜRR ND …

Stork Technical Services, located in Kwinana, Western Australia with a team of over 30 employees provides asset integrity and fabric maintenance services to the oil and gas, chemical, power and mining industries.

Stork Technical Services has been using the CR 35 NDT Computed Radiography scanner since 2019 and uses it with Iridium-192 in combination with high-sensitivity white imaging plates to perform Corrosion-Under-Insulation (CUI) radiography and digital gap shots which are…

Applus+ Entrusts DRIVE NDT with Digitization of NDT Workflow

Applus+ Germany is one of the largest providers of non-destructive testing (NDT) services in Germany and with more than 20,000 employees in over 70 countries is one of the largest companies in the industry worldwide.

In order to cement its leading position over the longer term, Applus+ is investing in future technologies. One of the key challenges of the future is the digitalization of all NDT processes. "A key promise is…

HD-CR 35 NDT from DÜRR NDT Increases Efficiency of Oil & Gas RT Inspection Task …

ENOD S.R.L is an NDT service company based in Buenos Aires, serving the energy sector in Argentina since August 1980.

ENOD is one of the largest service providers in Argentina, offering a wide range of inspection methods to fit their customers' needs. They have largely invested in the latest technologies to be one of the pioneers in their local market. A few years ago, they stepped into digital radiography to replace…