Press release

Windform®, the most appropriate composite materials for challenging and harsh applications

Windform® has passed the flammability UL 94 HB test and did not show degradation with VUV testingWindform® family of high performance composite materials by CRP Technology are unique in the field of Additive Manufacturing: the excellent thermal and mechanical properties make them the most suitable Laser Sintering materials to meet the demands of the most competitive and advanced sectors.

Windform® composite materials guarantee high standards of flexibility, elasticity, resistance (to damage from vibration, deformation, high and low temperatures, and liquids), and have been rated HB according to the flammability UL 94 test.

They were also exposed to vacuum ultraviolet radiation and did not show degradation.

Laser Sintering polyamide-based carbon fiber reinforced Windform® XT 2.0 and Windform® SP composite materials, along with LS polyamide-based glass-fiber reinforced Windform® GT and Windform® LX 3.0 composite materials, have been tested for their flammability rating.

The “Test for flammability of plastic materials for parts in devices and appliances” UL 94 was carried out on test specimens 1 to 3 mm thickness.

The result of the flammability UL 94 HB test reports Windform® XT 2.0, Windform® SP, Windform® GT and Windform® LX 3.0 have successfully obtained the HB classification.

Samples of Windform® LX 3.0 and Windform® SP were subjected to VUV testing by exposing to ~8 solar equivalents in LEO, with a wavelength range of 115-200 nm VUV radiation from a 30 W Hamamatsu L7292 deuterium lamp for 36 continuous hours.

Test results report “Windform® SP and Windform® LX 3.0 samples did not show degradation with VUV testing”.

Both test results confirm Windform are the most appropriate composite materials for challenging and harsh applications.

CRP Group is headquartered in Modena, Italy. The Group is made up of specialized companies (CRP Technology, CRP Service, CRP Meccanica, plus its US-based partner CRP USA) dedicated to providing clients with the very latest technological solutions. With more than 45 years of experience in the world of F1 and more than 20 years of experience in Additive Manufacturing, CRP Group is distinguished by its know-how in specific application fields including but not limited to: automotive and motorsports, design, aerospace, UAVs, marine, entertainment, defense, and packaging.

In 2010 CRP Group decided to invest in the new field of sustainable vehicles by creating Energica.

CRP Group acted as a technology and financial incubator, and it is still today the lead investor of Energica Motor Company, since it has become an independent entity.

Veronica Negrelli

Press Officer CRP Group

Via Cesare Della Chiesa, 21

41126 Modena

Italy

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Windform®, the most appropriate composite materials for challenging and harsh applications here

News-ID: 1018391 • Views: …

More Releases from CRP Group

CRP at MIA EEMS 2019

CRP will be attending the 2019 MIA EEMS Energy-Efficient Motorsport Conference (9 January, NEC Birmingham, UK) by showcasing the latest end use parts manufactured by cutting-edge Additive and Subtractive Manufacturing technologies for the most demanding sectors

The MIA Entertainment and Energy-Efficient Motorsport Conference (EEMS) in association with AVL RACING at Autosport International, will be held at NEC (Concourse Suites 1 & 2, B40 1NT) Birmingham, UK on the 9th of January…

CRP USA at 2018 SmallSat Conference

For the fourth year in a row CRP USA (www.crp-usa.net) will be attending the Small Satellite Conference and Exhibit at Utah State University, Logan, Utah, from August 4th to August 9th.

The event will be held at the Taggart Student Center, and CRP USA will be exhibiting at booth 43T.

They will be displaying cutting edge solutions for the space industry (http://www.crp-usa.net/aerospace-case-studies/) manufactured in the Windform family of high performance materials…

Updated 3D printed fairing for Ego Corsa

At the last series of tests carried on at the TT Circuit Assen, the 2019 Ego Corsa prototype was on track with a new 3D printed fairing with improved aerodynamics.

The 3D printed fairing was manufactured by CRP Technology via Laser Sintering using Windform XT 2.0 Carbon-fiber reinforced composite material.

“We have had the fairing available in short time” the Energica technical staff states.

Thanks to the professional 3D printing and…

Red Dot 2018: CRP Technology’s know-how helped to win Design Award!

Tundra®, Hexadrone’s first fully modular and easy-to-use drone for industrial and multi-purpose tasks, has won the Red Dot Award 2018 in the drone category.

The evaluation process (static test and assess) has been performed on the 3D printed Tundra® prototype manufactured by CRP Technology via Laser Sintering technology using Windform SP and Windform XT 2.0 Carbon-composite materials.

The award ceremony will be taking place in the Aalto-Theater, Essen (Germany) on…

More Releases for Windform

Excellent Electrical Insulation Performance for Windform Composites

3D printing service bureau CRP Technology's Glass fiber reinforced Windform thermoplastic composites were subjected to dielectric constant and dielectric strength tests, and the results were excellent, exhibiting a dielectric constant of approximately 4 and withstanding peak voltages of at least 2.5 kV/mm.

3D printing service bureau CRP Technology is pleased to inform that their Glass fiber reinforced Windform thermoplastic composites for Selective Laser Sintering, have demonstrated outstanding electrical insulation performance as…

Windform RS and Windform LX 3.0 officially approved for space flight

Carbon fiber reinforced composite Windform RS and Glass fiber reinforced composite Windform LX 3.0 from CRP Technology's Windform TOP-LINE, passed ESA standard screening outgassing tests in accordance with ESA-TEC-PR-002015 (based on ECSS-Q-ST-70-02C): they are officially approved for the construction of applications to launch into Space.

Franco Cevolini, CEO and Technical Director of CRP Technology, says: "Passing the outgassing tests is a crucial factor for those who supply materials to the…

Windform® RS, the outstanding composite material with amazing mechanical proper …

CRP Technology launches a new polyamide-based Carbon fiber filled composite for production-grade PBF 3D printing: the top-of-the-range Windform® RS. Engineer Franco Cevolini, CEO and CTO, CRP Technology: "In the Additive Manufacturing world Windform® RS is unparalleled. We created a material that combines high tensile strength with high elongation at break and low density: Windform® RS is unique of its kind"

CRP Technology, a leading 3D printing company, announces the…

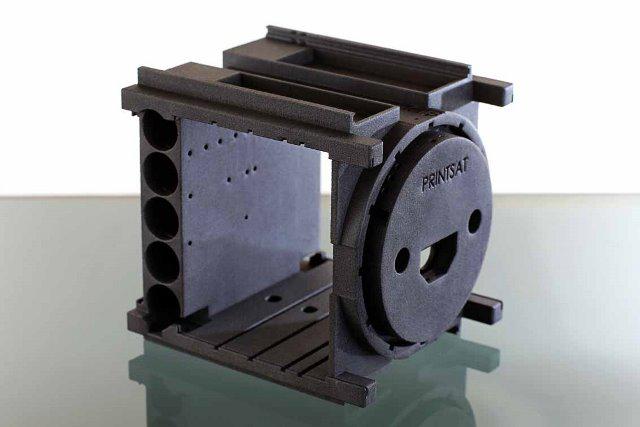

3D printed satellite deployer in Windform XT 2.0 acclaimed for its mechanical fe …

Recently Alba Orbital’s AlbaPod V2 hyped up for its unique design, lightweight, easily integration into space launch vehicles, maintenance of the demanding quality standards for space. These characteristics have also made possible thanks to the use of AM and Windform XT 2.0 Carbon composite material

The European Space Agency (ESA) dedicated an article on Alba Orbital's cutting edge 3D printed satellite dispenser, AlbaPod V2, manufactured by CRP Technology using laser sintering…

CRP Windform FR2, new cutting-edge composite material for Additive Manufacturing

CRP Technology, the long-standing leading company in the field of advanced technologies and professional 3D printing, launches on the market a flame-retardant glass fiber reinforced material for Selective Laser Sintering

CRP Technology's hi-tech advancement is unstoppable. Less than six months after the launch on the market of Windform FR1, the first carbon fiber-reinforced flame-retardant material for professional 3D printing, CRP Technology is presenting a new composite material from the TOP-LINE family…

CRP Technology launches Windform® P2, thermoplastic glass fiber filled material …

CRP Technology, a leading company in the creation of prototypes and final applications in professional 3D printing, launches Windform® P2 material.

Windform® P2 is a glass fiber reinforced thermoplastic polyamide material with excellent mechanical properties for High Speed Sintering process.

Engineer Franco Cevolini, CRP Technology CTO and VP, states: “Windform® P2 is the second polymer from P-LINE, the new Windform® range of materials for high speed production-grade 3D printing, introduced on the…