Press release

Carbide Inserts Market Shares And Strategies Of Key Players 2017 - 2025

Inserts are large-sized pieces of abrasive materials obtained by sintering a precursor powder into a consolidated mass. They are available in various shapes such as disks, rhombus, and triangles. The shape of the insert required in a tool is determined by the type of application. Commonly used cutting tool inserts are manufactured from ceramics (such as ceramic aluminum oxide and ceramic iron oxide) and carbides (such as silicon carbide (carborundum) and boron carbide).Carbide inserts, also known as cemented carbides, are composite materials. They are exceptionally hard materials employed in various industrial applications. For instance, they are used as cutting tool materials. Carbide inserts are manufactured as composites of carbide compounds cemented by a binder metal. Carbides that are commonly utilized in the manufacture of inserts include silicon carbide, boron carbide, and tungsten carbide. Sometimes, titanium carbide and tantalum carbide are also used as aggregates in carbide inserts.

Browse Research Report With Complete TOC @ https://www.transparencymarketresearch.com/carbide-inserts-market.html

Carbide inserts undergo coating in order to increase the life of carbide tools. Commonly used coatings are titanium nitride (TiN), titanium carbide (TiC), titanium carbide-nitride (Ti(C)N), and titanium aluminum nitride (TiAlN). Typically, lubricity and/or hardness of the tool increases when coatings are applied. Coating enables the clean pass of the cutting edge of a tool through the material. Temperature accompanying the cutting process also decreases due to coatings. This increases the tools’ life.

Deposition of coatings is typically carried out with the help of the thermal chemical vapor deposition (CVD) method. Certain applications require deposition of coatings with the mechanical physical vapor deposition (PVD) method. Deposition of coatings is an intricate process; complications in the process can result in adhesion failure of the coating.

Carbide inserts and other tools are able to withstand higher temperatures vis-à-vis standard high-speed steel tools at the point of contact between the cutter and work-piece. This enables carbide inserts to perform better surface finish of the work-piece and faster machining process.

In comparison, other typical materials employed in the manufacture of machining tools (including inserts) are cheaper than carbide. Furthermore, carbide is more brittle. This increases its susceptibility for chipping and breaking. In order to avoid this, the cutting tip is formed in the shape of a small insert, which is mounted on the tool body made from another material (such as carbon tool steel). This also provides the benefit of using carbide at the cutting interface without the high cost and brittleness of making the entire tool out of carbide.

In terms of material, the carbide inserts market can be segmented into silicon carbide, boron carbide, tungsten carbide, and others. Based on application, the market can be divided into grinding, cutting, polishing, milling, drilling, and others.

Request a PDF Brochure with Research Report Analysis @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=37331

In terms of geography, the carbide inserts market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific is the hub for a large number of manufacturers of carbide inserts. In terms of consumption as well as growth potential, Asia Pacific dominated the global carbide inserts market. The region is expected to continue its dominance in the near future. This can be ascribed to the technological advancements in automotive, medical, and aerospace industries in developing countries in Asia Pacific. Latin America and Middle East & Africa are likely to account for comparatively minor shares of the global carbide inserts market due to the lack of manufacturing facilities and their export-oriented economies. Europe is estimated to experience higher consumption of carbide inserts than North America.

Key players operating in the carbide inserts market include MITSUBISHI MATERIALS Corporation, Sandvik Coromant, Sandvik Hyperion, 3M, Carborundum Universal Ltd., Kennametal, Saint-Gobain, Element Six, KYOCERA Precision Tools Inc., and ISCAR LTD.

About Us

Transparency Market Research (TMR) is a market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants, use proprietary data sources and various tools and techniques to gather, and analyze information. Our business offerings represent the latest and the most reliable information indispensable for businesses to sustain a competitive edge.

Each TMR syndicated research report covers a different sector - such as pharmaceuticals, chemicals, energy, food & beverages, semiconductors, med-devices, consumer goods and technology. These reports provide in-depth analysis and deep segmentation to possible micro levels. With wider scope and stratified research methodology, TMR’s syndicated reports strive to provide clients to serve their overall research requirement.

US Office Contact

90 State Street, Suite 700

Albany, NY 12207

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Email: sales@transparencymarketresearch.com

Website: https://www.transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Carbide Inserts Market Shares And Strategies Of Key Players 2017 - 2025 here

News-ID: 991553 • Views: …

More Releases from Transparency Market Research

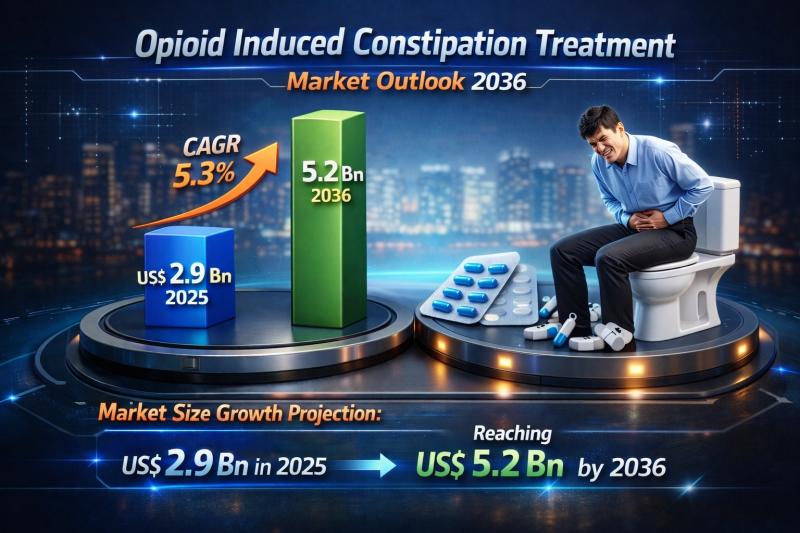

Global Opioid Induced Constipation Treatment Market Set to Reach USD 5.2 Billion …

The global opioid induced constipation (OIC) treatment market is witnessing steady and sustained growth as healthcare systems worldwide place increasing emphasis on comprehensive pain management and supportive care. Valued at US$ 2.9 billion in 2025, the market is projected to reach US$ 5.2 billion by 2036, expanding at a compound annual growth rate (CAGR) of 5.3% from 2026 to 2036. Growth is primarily fueled by the rising prevalence of chronic…

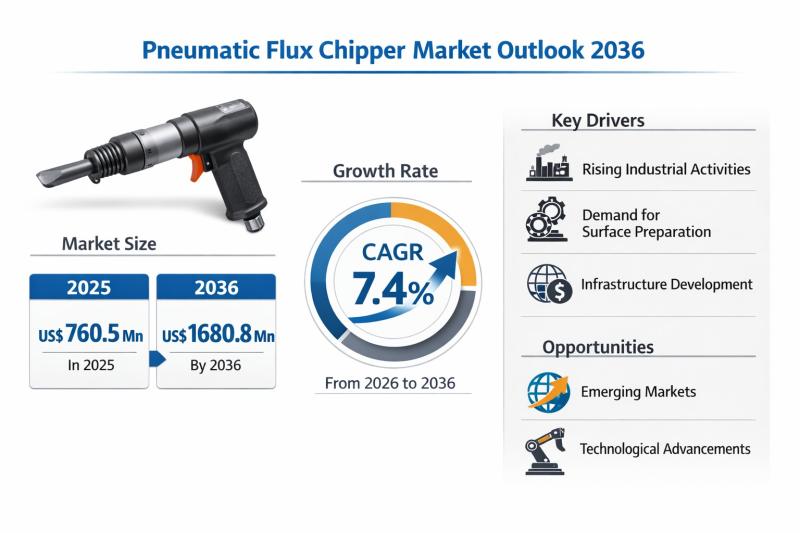

Pneumatic Flux Chipper Market Expanding at 7.4% CAGR Through 2036 - By Product T …

The global Pneumatic Flux Chipper Market is set to witness sustained and resilient growth over the next decade, underpinned by expanding heavy manufacturing activities, rising welding and fabrication demand, and continuous investments in industrial infrastructure across emerging and developed economies. According to the latest industry analysis, the market was valued at US$ 760.5 Mn in 2025 and is projected to reach US$ 1,680.8 Mn by 2036, expanding at a compound…

AI in Automotive Market Outlook 2036: Global Industry to Surge from US$ 19.8 Bil …

The AI in automotive market is entering a phase of exponential expansion, supported by rapid digitization of vehicles, growing safety mandates, and consumer demand for intelligent mobility. The global market was valued at US$ 19.8 Bn in 2025 and is projected to reach US$ 244.4 Bn by 2036, registering a remarkable CAGR of 27% from 2026 to 2036.

This growth trajectory reflects the transition of automobiles from mechanically driven products to…

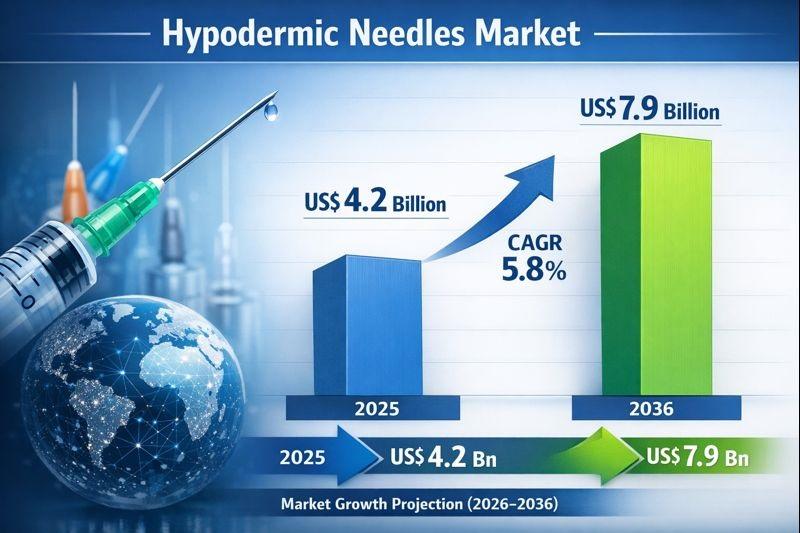

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…