Press release

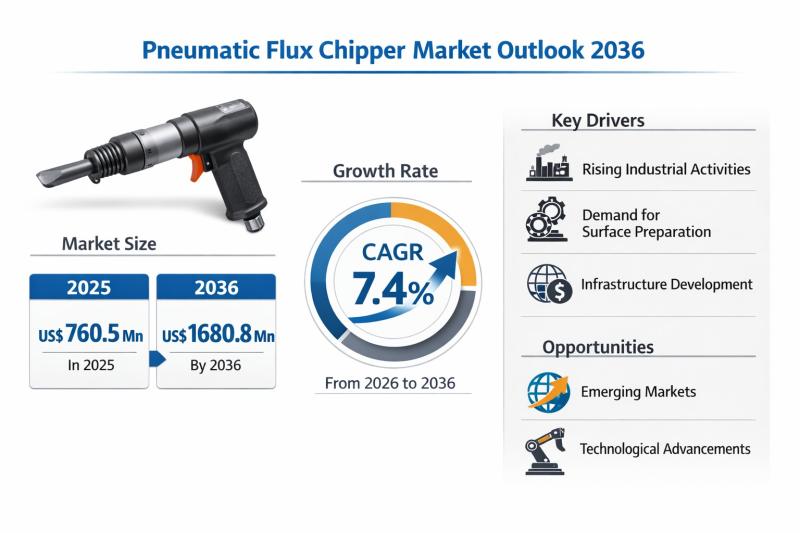

Pneumatic Flux Chipper Market Expanding at 7.4% CAGR Through 2036 - By Product Type / By Impact Frequency | China • India • Japan • U.S.

The global Pneumatic Flux Chipper Market is set to witness sustained and resilient growth over the next decade, underpinned by expanding heavy manufacturing activities, rising welding and fabrication demand, and continuous investments in industrial infrastructure across emerging and developed economies. According to the latest industry analysis, the market was valued at US$ 760.5 Mn in 2025 and is projected to reach US$ 1,680.8 Mn by 2036, expanding at a compound annual growth rate (CAGR) of 7.4% from 2026 to 2036.Review critical insights and findings from our Report in this sample -

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86929

Pneumatic flux chippers continue to play a critical role in post-weld surface finishing, ensuring weld integrity, inspection readiness, and compliance with stringent industrial quality and safety standards. Their durability, simplicity, and suitability for harsh industrial environments make them indispensable across a wide range of end-use industries.

Market Overview

A pneumatic flux chipper is a compressed-air-powered industrial hand tool used to remove welding slag, spatter, and residual flux from welded joints. These tools are widely adopted in environments where arc welding and flux-based welding processes are prevalent.

Pneumatic flux chippers are preferred over electric alternatives due to their:

• High impact force and consistent performance

• Lower risk of overheating and sparking

• Simple mechanical design with fewer failure points

• Compatibility with centralized compressed air systems

Available in straight and pistol-grip configurations, these tools are designed to meet varying ergonomic and operational requirements. Accessories such as vibration-dampening systems, noise-reduction attachments, and replaceable chisels further enhance their industrial appeal.

The market's relevance remains strong despite advancements in automation, as manual and semi-automated welding processes continue to dominate heavy industrial fabrication worldwide.

Key Market Growth Drivers

Expansion of Heavy Manufacturing & Fabrication

The growth of heavy manufacturing and metal fabrication industries remains the primary driver of the pneumatic flux chipper market. Industries such as shipbuilding, rail infrastructure, steel production, and power equipment manufacturing rely extensively on welding processes, necessitating efficient slag removal.

Rising industrial output in Asia Pacific-particularly in China and India-has resulted in sustained demand for rugged pneumatic tools. Fabrication contractors prefer pneumatic flux chippers due to their compatibility with large-scale compressed air systems and ability to operate continuously under demanding conditions.

Long Tool Life & Low Maintenance Costs

Another critical growth driver is the long operational life and low maintenance requirements of pneumatic flux chippers. Unlike electric or battery-powered tools, pneumatic chippers feature simpler mechanical construction, reducing downtime and lifecycle costs.

Key advantages include:

• Minimal electronics and circuitry

• Field-replaceable consumables such as chisels and seals

• Lower maintenance frequency in harsh environments

These benefits align well with procurement strategies of large industrial operators focused on minimizing operational disruptions and long-term ownership costs.

Emphasis on Safety, Ergonomics, and Productivity

Increasing occupational safety regulations and productivity expectations are driving demand for ergonomic, low-vibration pneumatic tools. Manufacturers are investing in lightweight materials, vibration-dampening designs, and improved noise control to enhance operator comfort and compliance with workplace safety norms.

Explore our report to uncover in-depth insights -

https://www.transparencymarketresearch.com/pneumatic-flux-chipper-market.html

Analysis of Key Players - Key Player Strategies

The global pneumatic flux chipper market is moderately consolidated, with several established manufacturers competing on durability, performance, and after-sales support. Leading companies include:

• APT Pneumatics Pvt. Ltd.

• Atlas Copco Group(Chicago Pneumatic)

• ATS ELGI

• Fuji Industrial Tools

• GISON Machinery Co., Ltd.

• HMT Air Tools

• JS Products Inc. (Steelman)

• MIGHTY SEVEN

• NITTO KOHKI CO., LTD.

• RalliWolf Industries Ltd.

• Sumake Industrial Co., Ltd.

• Toku Pneumatic Tool Mfg. Co., Ltd.

• Uryu Seisaku, Ltd.

• YOUN FA Pneumatic Co., Ltd.

Competitive Strategies Observed:

• Product durability and performance differentiation through hardened alloy steel and corrosion-resistant coatings

• Expansion of regional manufacturing footprints to reduce lead times and logistics costs

• Strong distributor and service networks to support after-sales requirements

• Focus on rental-friendly and heavy-duty tool designs

Manufacturers are also aligning closely with fabrication contractors and industrial customers to develop application-specific solutions.

Market Challenges & Opportunities

Challenges

Despite strong fundamentals, the market faces certain challenges:

• Competition from electric and battery-powered tools in light-duty

applications

• Price sensitivity in developing economies

• Dependence on industrial capital expenditure cycles

However, these challenges are largely mitigated by the continued dominance of pneumatic tools in heavy-duty and hazardous environments.

Opportunities

Key opportunities include:

• Growing infrastructure investment in Asia Pacific, the Middle East, and Africa

• Modernization of fabrication shops in emerging economies

• Integration with semi-automated welding lines

• Rising demand from construction equipment and industrial maintenance sectors

Manufacturers that invest in ergonomic innovation, regional expansion, and strong service support are well-positioned to capitalize on these opportunities.

Key Player Strategies

Leading players are adopting a mix of organic and inorganic strategies to strengthen their market presence:

• Development of ergonomic, low-vibration chippers

• Introduction of energy-efficient and noise-reduced designs

• Expansion into rental and maintenance markets

• Strategic partnerships with distributors and large fabrication contractors

Localization of manufacturing and assembly facilities is increasingly seen as a critical competitive lever, particularly in Asia Pacific and the Middle East.

Recent Developments

• In December 2025, Nitto Kohki announced the opening of a new manufacturing facility in Fukushima, Japan, featuring advanced automation, energy-efficient infrastructure, and workforce training initiatives to boost productivity and sustainability. This development is expected to positively impact the Global Pneumatic Flux Chipper market by strengthening production capacity, improving supply efficiency, and supporting long-term demand through enhanced manufacturing capabilities and regional industrial growth.

• In February 2025, Toku America Inc. participated in the American Rental Association (ARA) Show held in Las Vegas, where it showcased its STRIKER hydraulic breakers, equipment attachments, and handheld pneumatic tools. This development is significant for the Global Pneumatic Flux Chipper market, as it highlights rising manufacturer focus on rental-friendly, high-performance pneumatic tools, supporting market expansion through increased adoption in construction and industrial maintenance sectors.

Investment Landscape and ROI Outlook

The pneumatic flux chipper market presents a stable and attractive investment landscape, characterized by:

• Predictable replacement demand

• Long product lifecycles

• Strong linkage with infrastructure and industrial growth

Return on investment (ROI) is supported by recurring demand from fabrication-intensive industries and the relatively low risk of technological obsolescence.

Investors and manufacturers benefit from steady cash flows driven by consumables, spare parts, and service contracts.

Market Segmentations

By Product Type

• Straight

• Pistol

The straight segment dominated the market with 60.5% share in 2025, driven by superior impact energy transfer and suitability for heavy-duty applications.

By Impact Frequency

• Below 3,000 BPM

• 3,000 - 6,000 BPM

• 6,000 - 10,000 BPM

• Above 10,000 BPM

By End-use

• Metals & Steel Fabrication

• Marine Vessel & Shipbuilding

• Oil & Gas

• Power Generation

• Automotive

• Others (Railways, etc.)

By Distribution Channel

• Direct Sales

• Indirect Sales

By Region

• Asia Pacific (Dominant with 39.7% share in 2025)

• North America

• Europe

• Middle East & Africa

• Latin America

Asia Pacific leads due to its dense industrial base, government-led infrastructure spending, and high utilization of pneumatic tools in heavy manufacturing.

Why Buy This Report?

• Comprehensive market size and forecast analysis (2021-2036)

• In-depth evaluation of drivers, trends, challenges, and opportunities

• Detailed competitive landscape and company profiles

• Strategic insights for manufacturers, investors, distributors, and policymakers

• Actionable intelligence to support business expansion and investment decisions

Buy this Premium Research Report for exclusive, in-depth insights -

https://www.transparencymarketresearch.com/checkout.php?rep_id=86929<ype=S

FAQs

1. What is driving the growth of the pneumatic flux chipper market?

The market is driven by expanding heavy manufacturing, rising welding activity, long tool life, low maintenance costs, and increasing infrastructure investments.

2. Which region dominates the global market?

Asia Pacific dominates the market, accounting for 39.7% of global revenue in 2025.

3. Which product type holds the largest market share?

Straight pneumatic flux chippers lead the market due to their durability and suitability for heavy-duty applications.

4. What challenges does the market face?

Key challenges include competition from electric tools and sensitivity to industrial capital expenditure cycles.

5. What is the market outlook through 2036?

The market is expected to grow steadily at a CAGR of 7.4%, reaching US$ 1,680.8 Mn by 2036, supported by long-term industrial and infrastructure growth trends.

Explore Latest Research Reports by Transparency Market Research:

Warehousing & Sorting System Market - https://www.transparencymarketresearch.com/warehousing-sorting-system-market.html

Refrigerated Warehouse Automation Market - https://www.transparencymarketresearch.com/refrigerated-warehouse-automation-market.html

Flap Wheels Market - https://www.transparencymarketresearch.com/flap-wheels-market.html

Planetary Roller Screw Market - https://www.transparencymarketresearch.com/planetary-roller-screw-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Follow Us: LinkedIn| Twitter| Blog | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Pneumatic Flux Chipper Market Expanding at 7.4% CAGR Through 2036 - By Product Type / By Impact Frequency | China • India • Japan • U.S. here

News-ID: 4348185 • Views: …

More Releases from Transparency Market Research

AI in Automotive Market Outlook 2036: Global Industry to Surge from US$ 19.8 Bil …

The AI in automotive market is entering a phase of exponential expansion, supported by rapid digitization of vehicles, growing safety mandates, and consumer demand for intelligent mobility. The global market was valued at US$ 19.8 Bn in 2025 and is projected to reach US$ 244.4 Bn by 2036, registering a remarkable CAGR of 27% from 2026 to 2036.

This growth trajectory reflects the transition of automobiles from mechanically driven products to…

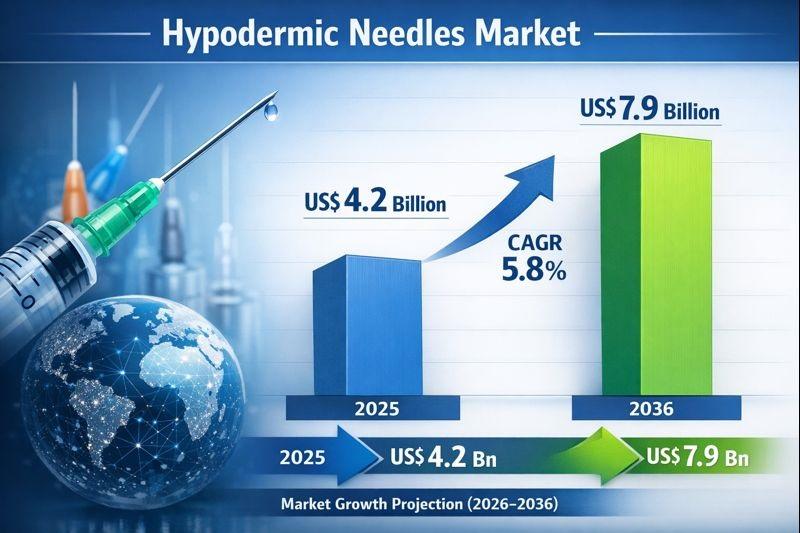

Hypodermic Needles Market to Reach US$ 7.9 Billion by 2036 on Rising Injectable …

The global hypodermic needles market was valued at approximately US$ 4.2 billion in 2025 and is projected to reach around US$ 7.9 billion by 2036, expanding at a CAGR of nearly 5.8% from 2026 to 2036, driven by the rising prevalence of diabetes, cancer, and chronic diseases, growing demand for injectable drugs and biologics, and the expansion of global vaccination and immunization programs; increasing adoption of safety-engineered and disposable needles,…

Connected Car Market to Reach US$ 467.2 Billion by 2036, Driven by Rising Adopti …

The global connected car market is entering a high-growth phase as vehicles increasingly evolve into software-defined, data-driven mobility platforms. Valued at US$ 100.8 billion in 2025, the market is projected to reach an impressive US$ 467.2 billion by 2036, expanding at a robust CAGR of 12.3% from 2026 to 2036. This growth is fueled by rapid advancements in automotive connectivity, rising consumer demand for intelligent features, and strong integration of…

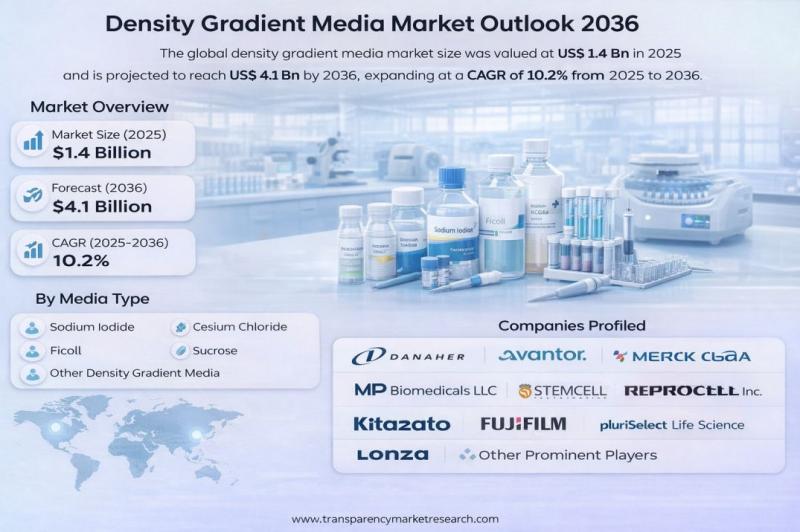

Density Gradient Media Market to Reach US$ 4.1 Billion by 2036, Driven by Rapid …

The global density gradient media market was valued at US$ 1.4 Billion in 2025 and is projected to reach US$ 4.1 Billion by 2036, expanding at a robust CAGR of 10.2% from 2025 to 2036. The market's rapid growth is primarily driven by increasing demand for rapid infectious disease screening, expanding cell therapy and immunology research, and continuous technological advancements improving sensitivity and multiplexing in laboratory workflows.

Access key findings and…

More Releases for Pneumatic

Pneumatic And Semi-Pneumatic Wheels Market Size by Type, Application, and Region …

USA, New Jersey- According to Market Research Intellect, the global Pneumatic And Semi-Pneumatic Wheels market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

Because they are used so extensively in sectors including automotive, material handling, construction, and agriculture, the pneumatic and semi-pneumatic wheel markets are seeing…

Pneumatic Chisel Hammers Market Size, Share and Forecast By Key Players-Bosch, N …

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- According to the MRI Team's Market Research Intellect, the global Pneumatic Chisel Hammers market is anticipated to grow at a compound annual growth rate (CAGR) of 7.77% between 2024 and 2031. The market is expected to grow to USD 23.07 Billion by 2024. The valuation is expected to reach USD 38.95 Billion by 2031.

Because pneumatic chisel hammers are so widely used in the metalworking, automotive, and construction industries, the market for…

Pneumatic Conveying System

Altomech is a renowned company that specializes in the design and manufacturing of advanced pneumatic conveying systems. Pneumatic conveying systems are vital in various industries for the efficient and dust-free transfer of bulk materials like powders, granules, and other particulate matter. Altomech has gained recognition for its innovative solutions and cutting-edge technology, making it a trusted partner for industries ranging from food and pharmaceuticals to chemicals and plastics.

Key Features and…

Pneumatic Comfort Takes the Wheel : Unveiling the Automotive Pneumatic Comfort S …

According to a recent report published by Allied Market Research, titled, "Automotive Pneumatic Comfort Seat System Market by Vehicle Type, Propulsion Type, and Function: Global Opportunity Analysis and Industry Forecast, 2020-2030," The global automotive pneumatic comfort seat system market was valued at $1.11 billion in 2020, and is projected to reach $2.03 billion by 2030, registering a CAGR of 6.5%.

North America dominates the market in terms of revenue, followed by…

Pneumatic Tourniquet

The global Pneumatic Tourniquet market is estimated to attain a valuation of US$ 1 Bn by the end of 2032, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 8% during the forecast period, 2022-2032.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders of…

Fact.MR Pneumatic Equipment Market Segmented By Product Type - pneumatic valves, …

Expanding Horizons in Healthcare and Food Sectors

Pneumatic equipment market has been gaining significant traction because of its utilization in nearly every field and broad application in the end-user industries. The use of pressurized gas for motion is called pneumatics, and upon compressing atmospheric air, there are equipment that can efficiently maintain a sustainable supply. The equipment that carry out such mechanisms to obtain movement are pneumatic equipment. Various pneumatic equipment…