Press release

WIRELESS LUBRICATION MONITORING WORLD NEWS!

The WLubeMon monitors that the right amount of lubricant is fed in the right time to the bearing – the fundamental criteria for reliable lubrication system.The system works completely independently and is capable to monitor all types of grease lubrication systems including manual lubrication.

The meter (LubeMon) has been available some years already but with cable transmission. The disadvantages have been high cost of cable installation as well as risk of cable damages.

The WLubeMon comprises a precision grease meter that measures the amount of lubricant fed into the lubrication point. The meter communicates on a regular basis wirelessly with a Control unit. The system provides alarm both for too high and too low volume as well as statistics and log functions.

The Control unit can monitor up till 20 individual meters and has normally a carriage of 75 meters. The condition for each meter is shown clearly on the Control unit. The Control unit is very user-friendly and has a color display

The battery lasts at least 15 years

We are convinced that many expensive bearing break downs will be avoided using this system as the user will be reminded already at the first missed lubrication occasion.

Assalub develops, manufactures and markets equipment for handling of lubricants as well as centralised lubrication systems and components for said systems. All Assalub products are known to represent a very high quality standard. Assalub is a privately-owned company with some forty employees. The company is exclusively devoted to lubrication automation and handling, and has no activity in other areas. The HQ, production, development and the warehouse are all located in Åtvidaberg, Sweden. Åtvidaberg is located 35 km east of Linköping which is the regional capital city – about 200 km south of Stockholm.

ins trade media service - INS Oy/Ab

Iso Roobertinkatu 20-22 Stora Robertsgatan

00120 Helsinki Helsingfors

Finland

Tel. + 358 9 6120 990

Fax + 358 9 6120 9919

eMail:katrin.leinonen(at)ins.fi

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release WIRELESS LUBRICATION MONITORING WORLD NEWS! here

News-ID: 978718 • Views: …

More Releases from ins trade media service

Bio-Gate concludes another cooperation agreement with leading multinational impl …

Medical technology business further strengthened

Coating of orthopaedic revision implants with HyProtect technology

Focus on protection against infections with multi-resistant germs

Nuremberg/Bremen, 5 July 2022 - Bio-Gate AG (ISIN DE000BGAG981), a leading provider in the field of innovative health technologies, has concluded a contract with a leading multinational medical device manufacturer for the coating of orthopaedic implants in human medicine. As part of the cooperation and the joint project management, Bio-Gate is responsible…

Walki introduces a broad portfolio of recyclable materials for the growing froze …

Walki is answering to the growing demand for frozen food by expanding its portfolio of recyclable materials.

The global market for frozen food is expected to grow to 322 billion euros by 2026. Although the demand is growing globally across all age groups, it is especially popular among younger consumers.

"Frozen food is an ideal way to prolong shelf life without losing out on the vitamins. It is also an excellent way…

Dassiet and OrthoPets collaborate to provide safer and easier orthopedic care fo …

The teams combine Dassiet’s clinically proven medical and material innovations with OrthoPets' strong experience in custom pet orthoses to provide human level care for animals.

The material innovation company Dassiet, and the leading, US based pet orthosis manufacturer OrthoPets have started collaboration to create sustainable, safe and user-friendly pet healthcare products. Both companies want to first tackle the issues surrounding veterinary casting, splints, and bandages, and to provide vets, pets and…

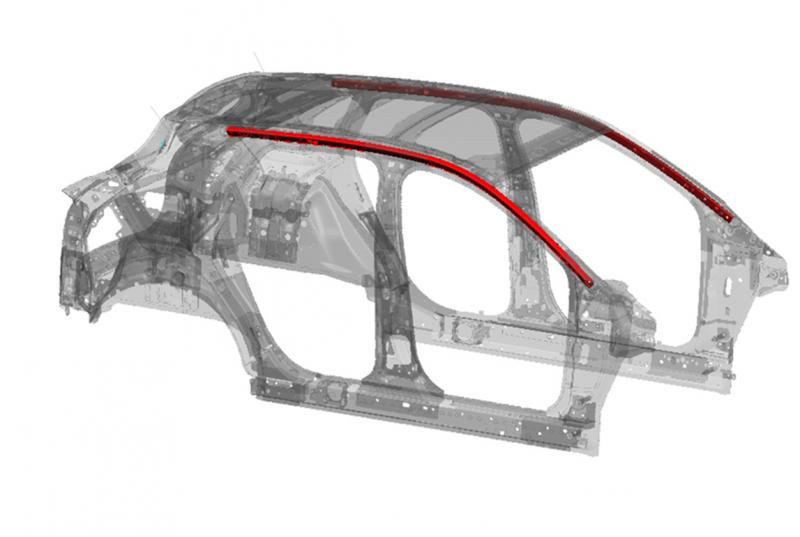

Shape Corp. wins Swedish Steel Prize 2019

The winner of the 20th international Swedish Steel Prize is Shape Corp. from the United States. The prize is awarded for the groundbreaking use of martensitic steel in a 3D formed tube for automotive roof rail applications.

“With great skill, Shape Corp. has shown the way forward and has succeeded in efficiently utilizing a modern material with the highest possible strength level. This shows a major opportunity in challenging other lightweight…

More Releases for Control

Top distributors of Access Control & Entrance Control Solutions

FOR IMMEDIATE RELEASE

CDN Technology Delivers Advanced Security and Workforce Solutions to Leading Enterprises in India

India - CDN Technology, (https://www.cdntechnology.co/) a trusted provider of access control, attendance, and security solutions, is strengthening India's enterprise and institutional security infrastructure with cutting-edge products and robust service delivery.

Specialising in biometric and AI-based face recognition attendance machines, access control systems, boom barriers (https://www.cdntechnology.co/products/boom-barrier), flap barriers, turnstiles, door frame metal detectors, and baggage scanners, CDN Technology…

Taking Control: Automotive Seat Control Modules Market Innovations

According to the recent findings by Persistence Market Research, sales of automotive seat control modules are anticipated to reach a value of US$ 8.95 Billion in 2022 with consistent long-term projections for the market. According to the report, the market will expand at 5.3% CAGR from 2022 to 2032. Automotive seat control modules are seeing increasing sales as customers demand more comfortable seats and various automobile interior accessories.

Integrated systems that…

Insect pest control Market Demand, Overview, Size, Trend, and Cleankill Pest Con …

Global Insect pest control report from Global Insight Services is the single authoritative source of intelligence on Insect pest control market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters' and PESTLE analysis. Report includes in-depth segmentation and market size data by categories, product…

Global Control Valves Market | Control Valves Industry | Covid-19 Impact Global …

Control valves refer to valves used in process industries to regulate process variables, such as flow, pressure, temperature, and fluid level in process industries including water management, chemicals, oil & gas, power generation, pharmaceuticals, automotive, mining, and food & beverages. These valves play a vital role in mounting efficiency, safety, and profitability of these process industries. Moreover, manufacturers of control valves are continually engaged in research & development (R&D) activities…

Turbine Control System Market Report 2018: Segmentation by Component (Sensors, H …

Global Turbine Control System market research report provides company profile for ABB (Switzerland), Siemens (Germany), Honeywell (US), Emerson (US), GE (US) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025, etc. The report also provides…

Global Acoustic Control System Market 2017 Acoustic Control, Oceaneering Interna …

Global Acoustic Control System sales will reach about 1011 billion USD in 2017 from 875 billion USD in 2012 all around the world, with the CAGR of 2.62%. The Leading growing markets are China, Southeast Asia, etc. USA, EU, Oceania, India, etc. is the mature market with low growth rate.

Global Acoustic Control System Market Size, Status and Forecast 2022 provides Market information about Manufacturers, Countries, Type and Application.This Acoustic Control…