Press release

Revolution in civil engineering works through extension of VAG BAIO®plus System

With its new VAG BETA® 200 MMB-Combi Gate Valve, VAG-Armaturen GmbH is introducing an extension of the successful BAIO®plus System. The new system consists of a VAG BETA® 200 SMB Gate Valve and two VAG BAIO®DVS Double-Socket Locks. So, from now on, the assembly and disassembly of flangeless cross junctions will be even faster and easier.For many years now, the DVGW [German Association for Gas and Water] has recommended the general use of flangeless valves in the construction of underground pipelines. Until now, the disadvantage of this method was the fact that if socket connections were used, they could not be detached, i.e. only be disassembled by cutting the pipeline.

By the combination of the new VAG BETA® 200 SMB Gate Valve with the VAG BAIO®DVS Double-Socket Lock, a socket connection has been created which can be disassembled on both sides. This detachable connection becomes possible due to the two halves of the BAIO®DVS Double-Socket Lock. The halves are held together by a clamping ring. By opening the clamping rings on both sides of the gate valve, the valve can be removed without the disassembly of any other components. The time-consuming cutting of pipelines and the subsequent bridging of the gaps by additional fittings is no longer necessary. The big advantage is that the working space required for the refurbishment of a pipeline section is now located inside the cross junction and longer has to be provided outside it.

On the one hand, this saves costs with regard to civil engineering works and on the other, handling the components is made considerably easier.

Besides an integrated gate valve, the VAG BETA® 200 MMB-Combi Gate Valve has two BAIO® spigot ends in the through pipe and a BAIO® Multi-Function Socket in the branch pipe. The BAIO®DVS Double-Socket Lock is equipped with a multi-function socket on both sides for the direct locking of spigot ends or for the connection to pipes made of commonly used materials such as PE, PVC and cast iron.

The evolution of the tried and tested VAG BAIO®plus System is its consistently boltless design which allows the considerably faster and easier assembly and disassembly of cross junctions.

VAG-Armaturen GmbH is a German company with more than 130 years of experience in the design and manufacturing of heavy-duty valves for all kinds of water applications. With nearly 1,000 employees worldwide the valve manufacturer is a globally active company and is setting new standards as a solution and system provider in water and wastewater technology. With over 180 sales representatives, 12 subsidiaries and 4 production facilities VAG is at home around the world.

VAG-Armaturen GmbH

Carl-Reuther-Str. 1

68305 Mannheim

Germany

Press contact: Michaela Wagner

Phone: +49 621 – 749 1680

Fax: +49 621 – 749 1338

Email: M.Wagner@vag-armaturen.com

Internet: www.vag-group.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Revolution in civil engineering works through extension of VAG BAIO®plus System here

News-ID: 85443 • Views: …

More Releases from VAG-Armaturen GmbH

VAG hands over donation to hospital hit by earthquake in Santiago de Chile

Last week, the VAG Group was able to hand over a donation cheque in the amount of € 10,000 to the Dr Felix Bulnes hospital in Santiago de Chile, the hospital which was destroyed by the earthquake.

Built as early as 1940, the hospital now ranges among the city’s largest hospitals and is the place to turn to for over one million inhabitants of the western parts of the city.…

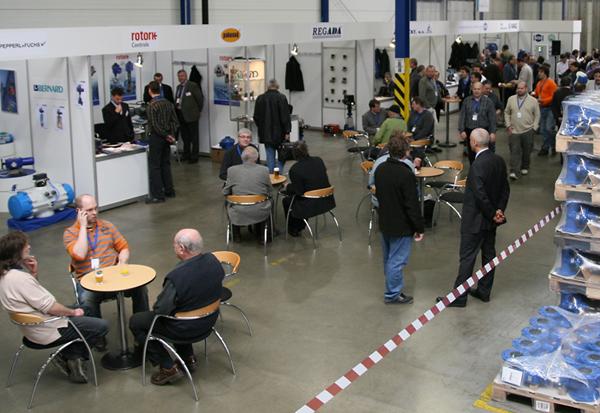

First “Actuator Day” of the VAG Group

On 4 March, the first “Actuator Day” of the VAG Group took place in Hodonín (Czech Republic). On this day, JMA, VAG’s Czech subsidiary, offered seven well-known manufacturers of actuators the possibility of presenting their range of products. Visitors to the in-house trade show included 200 prospective customers from the general industry, water supply industry, generation of energy sector and technology companies.

Manufacturers exhibiting their products included AUMA, REGADA and…

VAG Valves UK, “Building a Stronger Team”

VAG Valves UK in Partnership with Glasgow Caledonian University and Knowledge Transfer Partnerships (KTP) are undertaking a 2 year graduate development programme.

Knowledge Transfer Partnerships is Europe’s leading programme helping businesses to improve their skills base through better use of knowledge and technology that already exists within the UK.

VAG Valves UK along with Glasgow Caledonian University will employ a Graduate Engineer to work on new market opportunities for VAG in the…

First symposium on “Valves in Nuclear Power Plants”

From 9 to 10 February 2010, the first symposium on the subject of valves in nuclear power plants took place at VAG’s Mannheim headquarters.

During the two-day event, guests from ten German nuclear power plant locations attended expert talks, went on a guided tour through VAG’s Visitor Center and were also able to gain insights into the manufacture of special valves at the Mannheim plant.

The expert talks covered all relevant subjects,…

More Releases for VAG

First “Actuator Day” of the VAG Group

On 4 March, the first “Actuator Day” of the VAG Group took place in Hodonín (Czech Republic). On this day, JMA, VAG’s Czech subsidiary, offered seven well-known manufacturers of actuators the possibility of presenting their range of products. Visitors to the in-house trade show included 200 prospective customers from the general industry, water supply industry, generation of energy sector and technology companies.

Manufacturers exhibiting their products included AUMA, REGADA and…

VAG Valves UK, “Building a Stronger Team”

VAG Valves UK in Partnership with Glasgow Caledonian University and Knowledge Transfer Partnerships (KTP) are undertaking a 2 year graduate development programme.

Knowledge Transfer Partnerships is Europe’s leading programme helping businesses to improve their skills base through better use of knowledge and technology that already exists within the UK.

VAG Valves UK along with Glasgow Caledonian University will employ a Graduate Engineer to work on new market opportunities for VAG in the…

VAG-Valves UK awarded Yorkshire Water Framework

VAG-Valves UK and its UK Distribution and Logistics Partner Fusion Provida have recently been awarded the prestigious Yorkshire Water Framework for the supply of Resilient Seated Gate Valves (50mm – 300mm) for three years with an optional addition of two years.

VAG-Valves UK, Yorkshire Water and Fusion Provida recently visited the VAG manufacturing plants in Mannheim and Hodonin to sign the agreement and see firsthand the fantastic production and logistics facilities.

VAG-Valves…

VAG Awarded British Standard Kitemark approval for VAG BS750 Hydrant

VAG-Valves UK Ltd. is pleased to announce the award of the British Standards Institute Kitemark for our BS750 Underground Hydrant.

The award is the culmination of many months of hard work and effort by our manufacturing plants in Mannheim, Germany and Hodonin, Czech Republic.

This award further establishes VAG’s long term commitment to supply products to the UK Water Industry and its dedication to providing products to the highest achievable standards.

Well…

VAG Group also successful in Italy

VAG’s participation in the 9th ACCADUEO Exhibition and Conference in Ferrara (Italy) with over 10,000 visitors once again confirmed the valve manufacturer’s success in the Italian market.

The VAG Group received an overwhelmingly positive feedback from visitors for the products exhibited at the stand and the solutions provided in the areas of water, waste water and industrial applications. Besides giving various presentations on the subject of pressure management, VAG was…

New VAG UseCAD® 6.0

The new, sixth version of VAG UseCAD® is now available, just in time for IFAT. A total of five components were added to the previous version 5.0 that will assist demanding VAG customers in planning projects as well as in searching for specific product information about valves for water and sewage management.

An overview of the new program components:

• 3D images

• VAG screen saver

• Sound volume calculation for plunger valves

• Lay-out program for air and…