Press release

Running smoothness even at highest speeds. TIRA balancing station in a new railway wheels manufacturing line

The traffic safety of locomotives, rail cars and high-speed trains essentially depends on their wheels. An important criterion is the running smoothness which is affected by unbalances. They arrise when the rotation axis of the wheels does not comply with their axis of inertia in axial direction. Unbalances manifest themselves during the journey by vibrations and cause increased wear on the wheels, wheel bearings and undercarriage components and on the rails. For this reason, railway wheels must be tested for unbalances and be balanced during production and later during maintenance measures. Therefore, a balancing station is part of a new manufacturing line for railway wheels which was built by an internationally leading manufacturer of metal forming machines for a renowned manufacturer of railway wheels. This line has a length of approximately 200 m and contains several workstations where the starting material, cylindrical steel blanks, gradually is shaped, processed, measured and tested. The transportation and the delivery to the stations is automatically carried out by a linear portal, the cycle time is 60 secs. At the end of the line the wheels are tested and, if necessary, balanced in a balancing station for wheel discs which was developed and built by the testing machine manufacturer TIRA.Operating principle

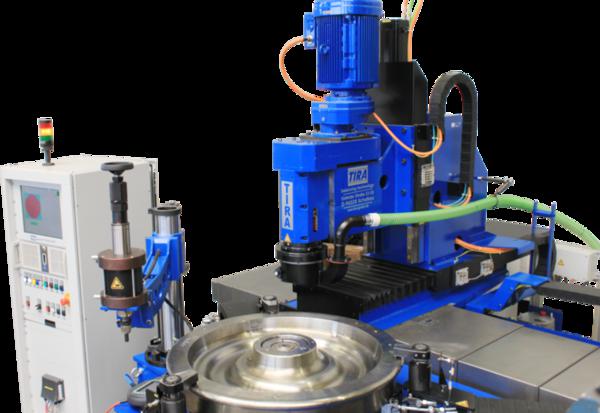

The balancing station consists of two force measuring vertical balancing machines type KV 1200 HA and type KV 1200 F which are essentially identical. The machine mentioned first is integrated in the production line, while the other one is installed off-line. The off-line machine is equipped with a POWERmaster type precision axis system from the Swiss company Otto Suhner, Division Automation. The control of the high performance machining spindle and the slide units, which are all new developments, is precisely adapted to the interaction with the balancing machine. The wheels are put automatically into the in-line balancing machine where the measurement of the unbalance and the turning to the marking position according to the UIC 812-3 and EN 13262 standards are carried out in one clamping. The process is done automatically and controlled by the operator of the complete line at its control desk.

The machine measures piezoelectrically the unbalance behaviour of each loaded wheel. In the case that the unbalance exceeds a predefined tolerance value, the machine determines the position at the wheel where a certain quantity of mass must be milled out in order to compensate the unbalance. As the entire process takes less than 45 secs it lies clearly within the takt of the production line. If the unbalance of a wheel needs more machining because of its size, the wheel is automatically inserted into the off-line balancing machine in order to be processed and finally guided into the manufacturing line again. In this case, the operator who is responsible for the off-line balancing machine has only the task of inserting the wheels into the take-up device, starting on a display the automatic measurement procedure and treatment processes and returning the wheels into the manufacturing line when the processes are terminated.

Using the measured values, the line control also calculates the milling path width, length and depth values which are actually necessary and controls the processing spindle. The chips which are produced during the milling are sucked off. After processing the unbalance behaviour of the wheel is measured again and controlled, and the unbalance position is marked. In this way, the line speed will not be effected. After leaving the balancing station, the wheels pass through a marking station in the manufacturing line and are then fully operational. The TIRA balancing machines are characterized by a fast, precise and clean operation and can be connected to a computer-aided quality (CAQ) management system.

Technical data

Balancing machine (model) KV 1200 HA / KV 1200 F

Wheel disc

Weight, max. (kg) 1500

Outside diameter (mm) 600 – 1350

Machine

Width x depth x height (mm³) 2500 x 4800 x 3250

Loading height (mm) 1100

Balancing speed (1/min) 400

Measuring uncertainty (gm) < 0.4

Cycle time < 45 secs. (KV 1200 HA)

< 4 min (KV 1200 F)

TIRA GmbH develops and manufactures measuring and testing systems. The company founded in 1947 is divided into the special fields vibration testing, material testing and balancing systems. About half of the approximately 130 employees are engineers or technicians. Up today, several thousand of TIRA systems are in use in a wide range of industries. Among the users there are automotive manufacturers and their suppliers, rolling-stock builders, manufacturers of aviation and aerospace equipment, manufacturers of electronic components as well as test centres and research institutes.

TIRA GmbH

Eisfelder Straße 23/25

D 96528 Schalkau

Web: www.tira-gmbh.de

Tel.: +49 (0) 36766 280 - 0

Fax: +49 (0) 36766 280 - 99

E-Mail: info@tira-gmbh.de

Andreas Zehner

Tel. +49 (0) 36766 280 20

E-Mail: andreas.zehner@tira-gmh.de

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Running smoothness even at highest speeds. TIRA balancing station in a new railway wheels manufacturing line here

News-ID: 733029 • Views: …

More Releases from TIRA GmbH

Press release to the oncoming trial against the ex-TIRA employees Mr. Volker S. …

TIRA Gmbh Schalkau wants to officially comment the running investigations of the two former TIRA employees:

It is true that the Attorney General investigates and will charge the former managing director Mr.Volker S. and the former sales manager Mr.Peter K. with suspicion of espionage for a foreign power as well as with the violation of foreign trade and financial laws. The trial will be held at the Higher Court of the…

More Releases for Balancing

Field Balancing Services Market Size, Share, Trends, Competitive Landscape, Regi …

The Field Balancing Services Market research report not only assists newly entered businesses but also assists businesses of all levels, shapes, scope, experience levels and sizes. This report also provides a way for key organizations to further expansion and business growth. Potential areas are spotted in this market research report for the business expansion. This research report reveals important insights into the market scenario to enable key players to take…

Balancing Machines Market |Balancing for Success: Maximizing Productivity with t …

In the past few years, the Balancing Machines market experienced a huge change under the influence of COVID-19 and Russia-Ukraine War, the global market size of Balancing Machines reached the predicted milestone in 2022 with the rising CAGR from 2017-2022. Facing the complicated international situation, the future of the Balancing Machines market is full of uncertain. Report predicts that the global Balancing Machines market size will expected to achieve a…

Exponential Growth Expected for Field Balancing Services Market With Complete SW …

Global Field Balancing Services Market Research Report provides a key analysis of the market status of the Field Balancing Services with the best facts and figures, meaning, definition, SWOT analysis, expert opinions, and the latest developments across the globe. The report also calculates the market size, Sales, Price, Revenue, Gross Margin, Market Share, cost structure, and growth rate. The report considers the revenue generated from the sales of This Report…

Automatic Positioning Balancing Machine Market Analysis and Growth: by Key Manuf …

Automatic Positioning Balancing Machine Market Research Report 2019 delivers detailed analysis of market and future prospects of Automatic Positioning Balancing Machine market and the report provide a fundamental analytical guide on the trends and advancements in this industry. Further, it gives details, prerequisite, and features of Automatic Positioning Balancing Machine market that boost the growth of the Automatic Positioning Balancing Machine industry.

Get Sample Copy of this Report -https://www.orianresearch.com/request-sample/808273

Market Overview: The…

Balancing Valves Market Report 2018: Segmentation by Type (Automatic Balancing V …

Global Balancing Valves market research report provides company profile for Oventrop, IVAR Group, Honeywell, Armstrong, Grinnell, Nibco, IMI Hydronic, Danfoss, Frese A/S, Caleffi, VIR Group, Crane Fluid Systems and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018…

Single Vertical Balancing Machine Market Report 2018: Segmentation by Type (Manu …

Global Single Vertical Balancing Machine market research report provides company profile for Schiak, Beijing Keeven, Balance United, Shanghai Jianping, BalanStar, BalanceMaster, Nan Jung, CEMB, SCHENCK, KOKUSAI Co., Ltd., DSK, Haimer, CWT and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…